Preparation method and application of rice bran powder

A technology of rice bran powder and rice bran, which is applied in the field of preparation of rice bran powder, and can solve problems such as poor absorption and poor taste of rice bran powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

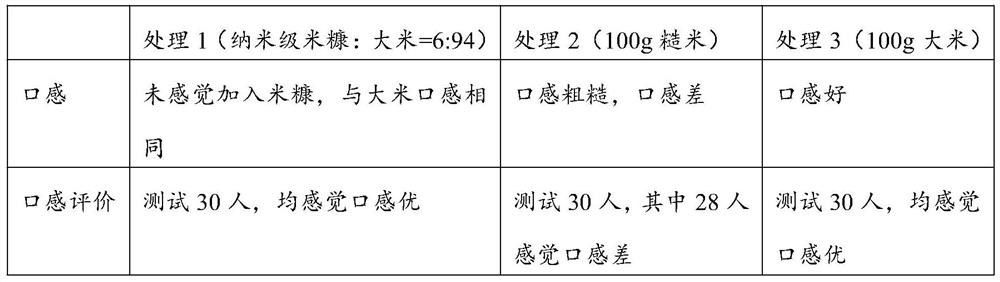

Examples

preparation example Construction

[0018] The invention provides a preparation method of rice bran powder, comprising the following steps:

[0019] The rice bran is microwaved to obtain stable rice bran;

[0020] The stabilized rice bran is subjected to nano-pulverization to obtain rice bran powder.

[0021] In the present invention, the rice bran is subjected to microwave treatment to obtain stable rice bran. In the present invention, the frequency of the microwave treatment is preferably 2000-2800 Hz, more preferably 2100-2700 Hz; the microwave treatment time is preferably 5-60 min, more preferably 7-54 min; The surface temperature is preferably 60 to 70°C, more preferably 62 to 68°C. In the present invention, the moisture content of the stabilized rice bran is preferably 5 to 7%. The invention can achieve the effects of killing enzymes, sterilization and dehydration after microwave treatment, and can solve the problem that rice bran is not easy to store; further, the invention adopts specific microwave tr...

Embodiment 1

[0038] Purification of rice bran: first remove the rice husk, then remove heavy metals and soil ash by using a paddy removal equipment, and finally use a rice polisher to grind to obtain purified rice bran for use;

[0039] Microwave treatment: The fresh rice bran is purified by microwave treatment. Treatment conditions: microwave frequency is 2450Hz, material surface temperature is 60°C, and treatment time is 45 minutes. Stabilized rice bran with sterilization, sterilization and moisture content of 6% was obtained.

[0040] Nano-pulverizing treatment: adding the stabilized rice bran into a nano-pulverizer for pulverization to obtain nano-scale rice bran with a particle size of 150-900 nm. The time for pulverizing rice bran was 240 min, and the temperature was 37 °C.

[0041] Product packaging: The nano-scale rice bran powder with a particle size of 150-900nm is packaged into 5g small packages.

Embodiment 2

[0043] Making Rice Bran Yogurt:

[0044] Using a household yogurt machine, add 5% sucrose in fresh milk, heat and sterilize, and add nano-scale rice bran powder (the rice bran powder prepared in Example 1) at 0%, 2%, 5%, 7%, 10%, 15% to obtain a mixed material, the bacterial source is commercially available Mengniu yogurt, and the inoculation amount is 10% of the mixed material. Fermentation at 37°C for 16 hours (the fermenting bacteria are Lactobacillus bulgaricus and Streptococcus thermophilus, the inoculation ratio is 1:1), and after being cooked at 4°C for 24 hours, rice bran yogurt with different rice bran concentrations was obtained and tasted. 15 people participated, and all agreed that The yogurt with rice bran tasted better, 10 people thought 7% tasted good, and 5 people thought 10% tasted good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com