Bicontinuous nanoporous carbon material co-doped with nitrogen and oxygen, its preparation method and application

A nanoporous carbon and co-doping technology, which is applied in the field of preparation of nanoporous carbon materials, can solve the problems of restricting practical applications, affecting the electrochemical performance of porous carbon materials, affecting the porous structure, etc., achieving low cost and excellent electrochemical performance , highly controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

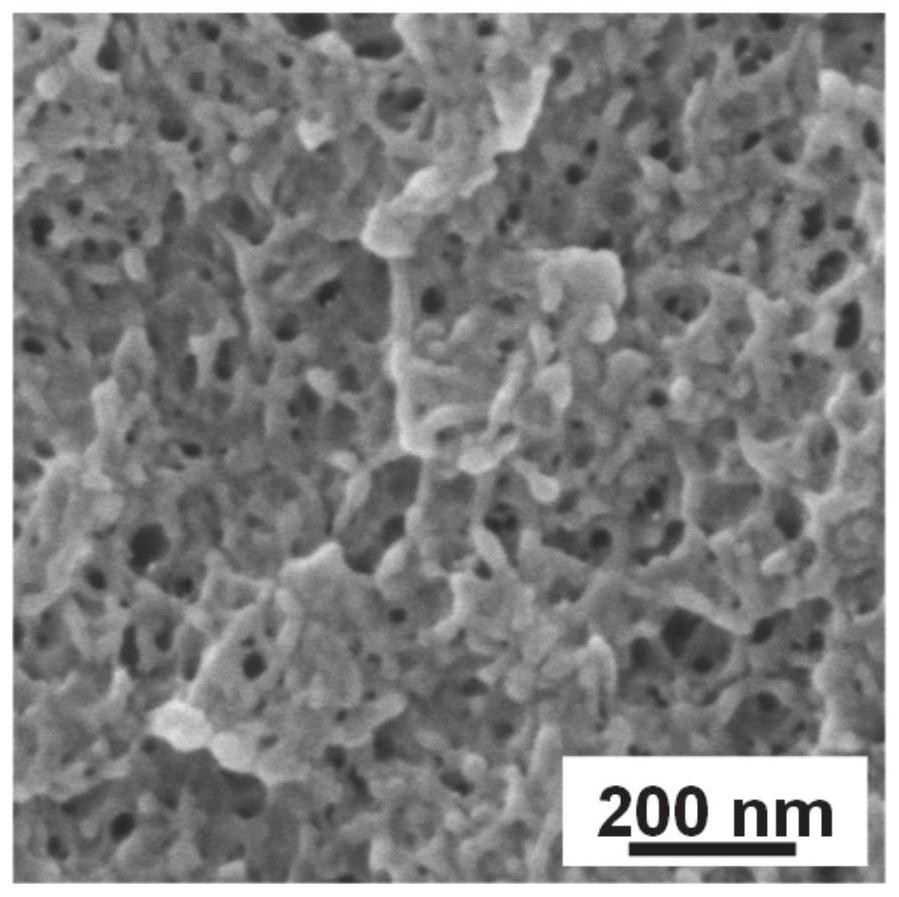

[0041] This embodiment provides a kind of better preparation method, and its steps are as follows:

[0042] (1) Polyacrylonitrile is fully dissolved in dimethyl sulfoxide to form a homogeneous solution and then dried to obtain a polyacrylonitrile film precursor;

[0043] (2) The polyacrylonitrile film precursor is placed in an autoclave connected to a carbon dioxide cylinder, and the polyacrylonitrile film is fully saturated with carbon dioxide gas by controlling the temperature and pressure of the autoclave;

[0044] (3) rapidly release the carbon dioxide in the autoclave, and immerse the saturated polyacrylonitrile film in the water bath for 50~70s in the step (2) to obtain the polyacrylonitrile nanoporous foam;

[0045] (4) Pre-oxidize and carbonize the polyacrylonitrile nanoporous foam to obtain a bicontinuous nanoporous carbon material co-doped with nitrogen and oxygen.

[0046] The present invention uses the nitrogen-oxygen co-doped bicontinuous nanoporous carbon materi...

Embodiment 1

[0053] The preparation method of the nitrogen-oxygen co-doped bicontinuous nanoporous carbon material involved in this embodiment comprises the following steps:

[0054] (1) Fully dissolve polyacrylonitrile in dimethyl sulfoxide to form a uniform solution, and the mass ratio of the two is 1:9. Pour the uniform solution into a petri dish, and dry it at 60°C for 24 hours to obtain a polyacrylonitrile film precursor;

[0055] (2) Place the polyacrylonitrile film precursor in an autoclave connected to a carbon dioxide cylinder, and keep the temperature and pressure of the autoclave at 40°C and 17.24MPa respectively for 4 hours to make the polyacrylonitrile film Fully saturated with carbon dioxide gas;

[0056] (3) Rapidly release the carbon dioxide in the autoclave (the pressure relief rate is about 90MPa s -1 ), and immerse the saturated polyacrylonitrile film in a water bath at 80° C. for about 1 min to obtain polyacrylonitrile nanoporous foam in step (2);

[0057] (4) The ab...

Embodiment 2

[0062] The preparation method of the nitrogen-oxygen co-doped bicontinuous nanoporous carbon material involved in this embodiment comprises the following steps:

[0063] (1) Fully dissolve polyacrylonitrile in dimethyl sulfoxide to form a uniform solution, and the mass ratio of the two is 1:9. Pour the uniform solution into a petri dish, and dry it at 60°C for 24 hours to obtain a polyacrylonitrile film precursor;

[0064] (2) Place the polyacrylonitrile film precursor in an autoclave connected to a carbon dioxide cylinder, and keep the temperature and pressure of the autoclave at 40°C and 17.24MPa respectively for 4 hours to make the polyacrylonitrile film Fully saturated with carbon dioxide gas;

[0065] (3) Rapidly release the carbon dioxide in the autoclave (the pressure relief rate is about 90MPa s -1 ), and immerse the saturated polyacrylonitrile film in a water bath at 80° C. for about 1 min to obtain polyacrylonitrile nanoporous foam in step (2);

[0066](4) The abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com