Antioxidant for thin film encapsulation, composition and application of composition

A thin-film encapsulation and antioxidant technology, which is applied in the field of thin-film encapsulated antioxidants and compositions, can solve the problems of decreased flatness of inorganic films, adverse effects of devices, and rises.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

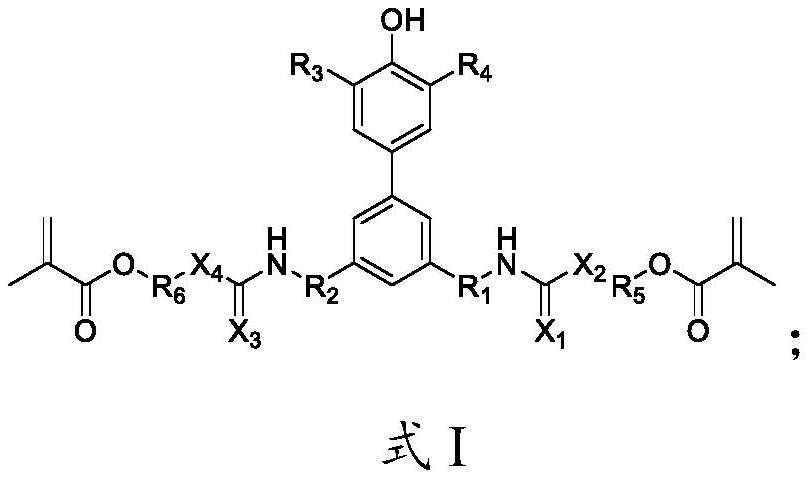

[0044] This antioxidant embodiment provides a kind of antioxidant for film encapsulation, and its synthetic route is as follows:

[0045]

[0046] Concrete, the preparation method of this antioxidant comprises the following steps:

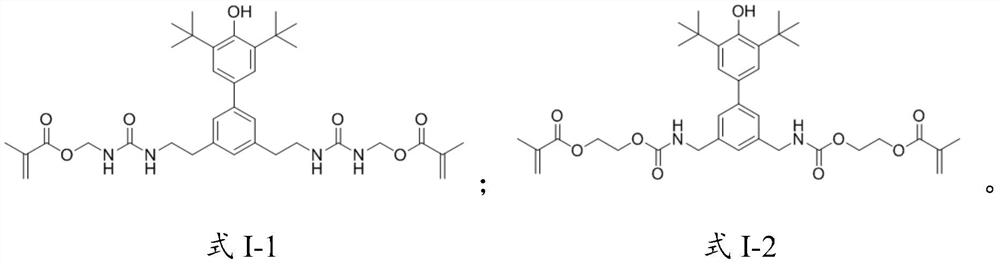

[0047] Add 78 g of 3',5'-bis(2-aminoethyl)-3,5-di-tert-butyl-4-biphenol and 66 g of isocyanate methyl methacrylate to dissolve in 300 mL of toluene, and add 0.6 g Dibutyltin dilaurate was stirred while heating at 60° C. for 4 hours; then, the temperature was cooled to room temperature, and the solvent was removed using a vacuum distiller to obtain 106 g of an antioxidant. The structural formula of this antioxidant is as follows:

[0048]

[0049] This antioxidant is detected and analyzed, and the specific results are as follows:

[0050] HPLC purity: greater than 90%.

[0051] Mass spectrum: calculated value 650.82; found value 650.03.

[0052] Elemental analysis:

[0053] Calculated values: C: 66.44%; H: 7.74%; N: 8.61%; O: 17.21%.

[...

Embodiment 2

[0056] This antioxidant embodiment provides a kind of antioxidant for film encapsulation, and its synthetic route is as follows:

[0057]

[0058] Concrete, the preparation method of this antioxidant comprises the following steps:

[0059] Add 83 g of 3',5'-bis(2-aminoethyl)-3,5-di-tert-butyl-4-biphenol and 61 g of isocyanate methyl methacrylate to dissolve in 300 mL of toluene, and add 0.6 g Dibutyltin dilaurate was stirred while heating at 60° C. for 4 hours; then, the temperature was cooled to room temperature, and the solvent was removed using a vacuum distiller to obtain 106 g of an antioxidant. The structural formula of this antioxidant is as follows:

[0060]

[0061] This antioxidant is detected and analyzed, and the specific results are as follows:

[0062] HPLC purity: greater than 90%.

[0063] Mass Spectrum: Calculated 652.79; Tested 651.68.

[0064] Elemental analysis:

[0065] Calculated: C: 66.24%; H: 7.41%; N: 4.29%; O: 22.06%.

[0066] The test val...

Embodiment 3

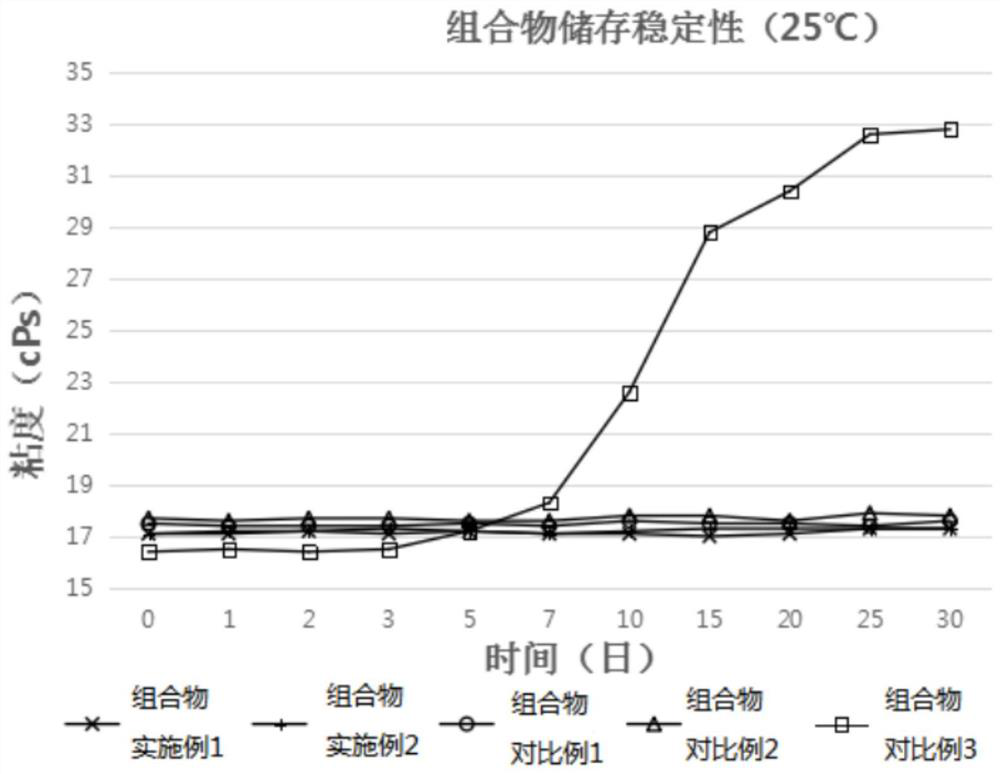

[0078] This composition example provides a composition for film encapsulation, and its preparation method includes the following steps: 0.5g of the antioxidant provided in the above antioxidant example 1, 99g of 2-phenoxyethyl acrylic acid, 0.5 g of 2,2'-diethoxyacetophenone was put into the reactor and stirred for 30 minutes, and then filtered through a 0.45 μm Teflon filter to obtain a composition for film encapsulation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com