Preparation method of novel anti-static anti-ultraviolet fiber

An anti-ultraviolet and anti-static technology, applied in the direction of conductive/anti-static filament manufacturing, fiber treatment, fiber chemical characteristics, etc., can solve the problems of affecting the scope of use, limiting the scope of application, additional pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

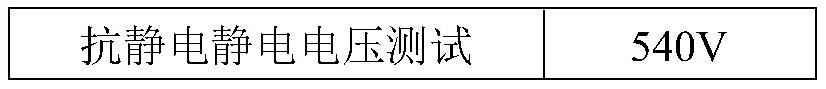

Examples

Embodiment 1

[0025] The mass ratio of PET and PA6 is 1:2.

[0026] Preparation of PA6 antibacterial functional material: The conductive zinc oxide nanopowder deposited on the surface of titanium dioxide and PA6 polyester material are prepared by twin-screw melt blending and extruding into spinning-grade chips with antistatic function. The twin-screw processing temperature is 255 °C, the screw speed is 300r / min, the particle size of the nano-functional powder is 80nm, and the weight percentage of the nano-functional powder in the PA6 functional slice is 2%.

[0027] Preparation of PET anti-ultraviolet functional materials: compound UV1020 anti-ultraviolet and weather resistance additives and dibutyltin according to the mass ratio of 10:1, dissolve them in ethylene glycol, carry out polymerization by in-situ polymerization, and then pelletize to prepare spinning grade slices, the polymerization temperature is 282°C, and the content of the anti-ultraviolet compound reagent in the PET function...

Embodiment 2

[0034] The mass ratio of PET and PA6 is 1:2.

[0035] Preparation of PA6 antibacterial functional material: The conductive zinc oxide nanopowder deposited on the surface of titanium dioxide and PA6 polyester material are prepared by twin-screw melt blending and extruding into spinning-grade chips with antistatic function. The twin-screw processing temperature is 255 °C, the screw speed is 300r / min, the particle size of the nano functional powder is 80nm, and the weight percentage of the nano functional powder in the PA6 functional slice is 4%.

[0036] Preparation of PET anti-ultraviolet functional materials: compound UV1020 anti-ultraviolet and weather resistance additives and dibutyltin according to the mass ratio of 10:1, dissolve them in ethylene glycol, carry out polymerization by in-situ polymerization, and then pelletize to prepare spinning grade slices, the polymerization temperature is 282°C, and the content of the anti-ultraviolet compound reagent in the PET function...

Embodiment 3

[0043] The mass ratio of PET and PA6 is 1:2.

[0044] Preparation of PA6 antibacterial functional material: The conductive zinc oxide nanopowder deposited on the surface of titanium dioxide and PA6 polyester material are prepared by twin-screw melt blending and extruding into spinning-grade chips with antistatic function. The twin-screw processing temperature is 255 °C, the screw speed is 300r / min, the particle size of the nano-functional powder is 80nm, and the weight percentage of the nano-functional powder in the PA6 functional slice is 6%.

[0045] Preparation of PET anti-ultraviolet functional materials: compound UV1020 anti-ultraviolet and weather resistance additives and dibutyltin according to the mass ratio of 10:1, dissolve them in ethylene glycol, carry out polymerization by in-situ polymerization, and then pelletize to prepare spinning grade slices, the polymerization temperature is 282°C, and the content of the anti-ultraviolet compound reagent in the PET function...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com