Down feather flocculus production process

A production process and technology of down, which is applied in the field of down flakes, can solve the problems of thick down flakes, easy drilling, not suitable for processing down jackets, etc., and achieve good warmth retention effect and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A down batting, comprising the following components in weight percentage: 15% of acrylic rubber powder, 10% of glue, 35% of down and 40% of down.

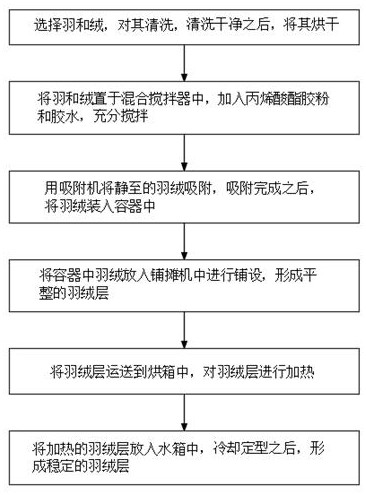

[0030] A production process of down flakes, comprising the following steps:

[0031] ①. Select feather and velvet, wash them, and dry them after cleaning;

[0032] ②. Put the feather and down in a mixing mixer, add acrylic rubber powder and glue, and stir thoroughly;

[0033] 35% feathers and 40% cashmere are placed in a mixing mixer, 15% acrylate rubber powder and 10% glue are added, the rotation speed of the mixing mixer is 1000r / min, the stirring time is 0.5h, and the rest time is 1h, forming Down.

[0034] ③. Use an adsorption machine to absorb the static down. After the adsorption is completed, put the down into the container;

[0035] Use an adsorption machine to absorb the down from the mixing agitator by means of vacuum adsorption, and then put the absorbed down into a container, and the container can be a cloth b...

Embodiment 2

[0043] A down batting, comprising the following components in weight percentage: 15% of acrylic rubber powder, 10% of glue, 35% of down and 40% of down.

[0044] A production process of down flakes, comprising the following steps:

[0045] ①. Select feather and velvet, wash them, and dry them after cleaning;

[0046] ②. Put the feather and down in a mixing mixer, add acrylic rubber powder and glue, and stir thoroughly;

[0047] 35% feathers and 40% cashmere are placed in a mixing mixer, 15% acrylate rubber powder and 10% glue are added, the rotation speed of the mixing mixer is 1000r / min, the stirring time is 0.5h, and the rest time is 1h, forming Down.

[0048] ③. Use an adsorption machine to absorb the static down. After the adsorption is completed, put the down into the container;

[0049] Use an adsorption machine to absorb the down from the mixing agitator by means of vacuum adsorption, and then put the absorbed down into a container, and the container can be a cloth b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com