Raw material composition of calcium fortified milk, calcium fortified milk and preparation method thereof

A raw material composition, calcium fortification technology, applied in the preservation of milk, milk preparations, other dairy products, etc., can solve the problems of inability to pass high temperature destructive storage experiments, low calcium content in milk, etc. Improved bone health, rich and smooth taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This embodiment provides a preparation method of calcium fortified milk.

[0043] The whole raw milk was filtered with an ultrafiltration membrane, and the membrane filtration temperature was 2°C. The retentate was used for subsequent production. The protein content in the retentate was 3.6g / 100mL, and the fat content was 4.0g / 100mL.

[0044] The raw material formula is shown in the table below in the present embodiment.

[0045] raw material technical indicators Amount added (wt%) colostrum basic protein Protein content ≥ 80% 0.0095 Micronized Milk Mineral Salt Particle size 0.173 Vitamin D Vitamin D3 content 100000~120000IU / g 0.001 gellan gum High acyl gellan gum 0.025 Compound emulsifier Soy lecithin: mono-, diglyceride fatty acid ester: sodium hexametaphosphate = 1:3:1 0.15 retentate Protein 3.6g / 100mL, fat 4.0g / 100mL margin total 100

[0046] The preparation method is carried out sequentially...

Embodiment 2

[0053] This embodiment provides a preparation method of calcium fortified milk.

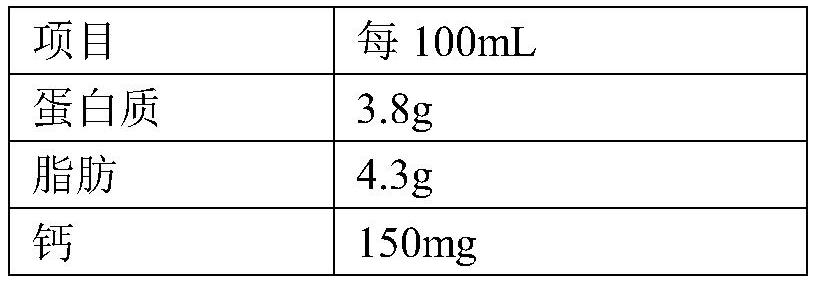

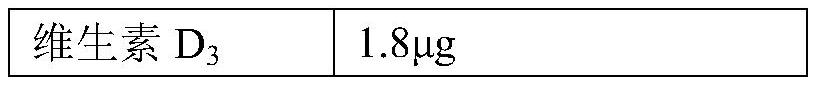

[0054] Whole raw milk was filtered with an ultrafiltration membrane at a temperature of 6°C, and the retentate was used for subsequent production. The protein content in the retentate was 3.8g / 100mL, and the fat content was 4.3g / 100mL.

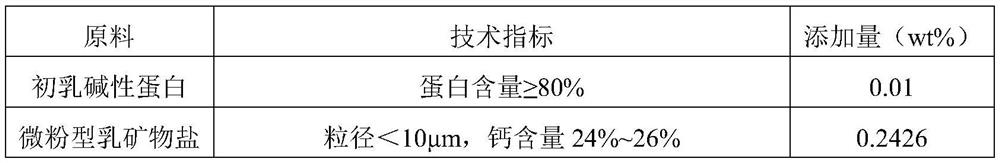

[0055] The raw material formula is shown in the table below in the present embodiment.

[0056] raw material technical indicators Amount added (wt%) colostrum basic protein Protein content ≥ 80% 0.01 Micronized Milk Mineral Salt Particle size 0.355 Vitamin D Vitamin D3 content 100000~120000IU / g 0.0012 gellan gum High acyl gellan gum 0.027 Compound emulsifier Soy lecithin: mono-, diglyceride fatty acid ester: sodium hexametaphosphate = 1:4:1 0.20 retentate Protein 3.8g / 100mL, fat 4.3g / 100mL margin total 100

[0057] The preparation method is carried out sequentially according to the followin...

Embodiment 3

[0064] This embodiment provides a preparation method of calcium fortified milk.

[0065] The whole raw milk was filtered with an ultrafiltration membrane, and the membrane filtration temperature was 4°C. The retentate was used for subsequent production. The protein content in the retentate was 3.8g / 100mL, and the fat content was 4.3g / 100mL.

[0066] The raw material formula is shown in the table below in the present embodiment.

[0067] raw material technical indicators Amount added (wt%) colostrum basic protein Protein content ≥ 80% 0.0095 Micronized Milk Mineral Salt Particle size 0.1465 Vitamin D Vitamin D3 content 100000~120000IU / g 0.001 gellan gum High acyl gellan gum 0.026 Compound emulsifier Soy lecithin: mono-, diglyceride fatty acid ester: sodium hexametaphosphate = 1:3:1 0.15 retentate Protein 3.8g / 100mL, fat 4.3g / 100mL margin total 100

[0068] The preparation method is carried out sequentiall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com