A method for preparing spherical powder of high-strength titanium alloy for additive manufacturing

A spherical powder, additive manufacturing technology, applied in the field of powder metallurgy, to achieve the effect of simplifying the method, improving the service life and increasing the atomization speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

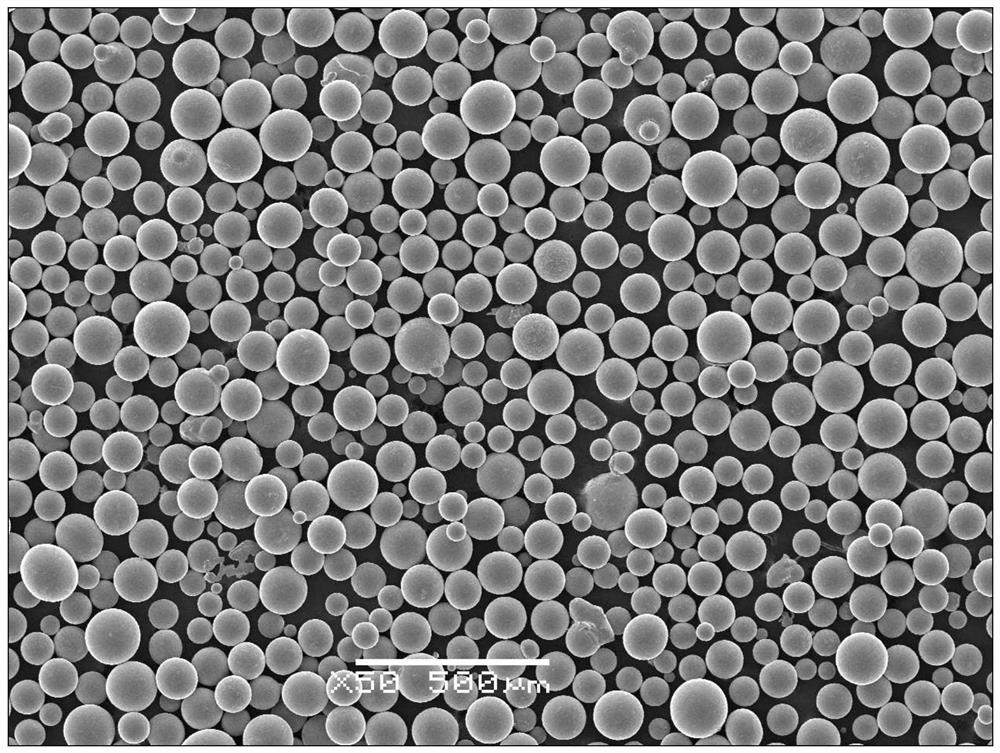

Image

Examples

Embodiment 1

[0030] This embodiment includes the following steps:

[0031] Step 1, finishing the titanium alloy electrode rod; the composition of the titanium alloy electrode rod is Ti-1Al-8V-5Fe, the tensile strength is 1458MPa, and the diameter is 80mm; the process of the finishing process is: before and after Male and female thread processing, surface finishing, fine grinding and straightening;

[0032] Step 2. Put the finished titanium alloy electrode rod into the dynamic seal of the plasma rotary electrode atomization powder making equipment in step 1, and vacuum the plasma rotary electrode atomization powder making equipment to atomize the plasma rotary electrode The vacuum degree in the milling equipment is 0.8×10 -3 Pa; the dynamic seal adopts a ball bearing structure, and the sealing ring of the dynamic seal is made of polyurethane;

[0033] Step 3. Introduce the mixed gas into the plasma rotary electrode atomization powder making equipment after vacuuming in step 2, and then st...

Embodiment 2

[0038] This embodiment includes the following steps:

[0039] Step 1, finishing the titanium alloy electrode rod; the composition of the titanium alloy electrode rod is Ti-1Al-8V-5Fe, the tensile strength is 1453MPa, and the diameter is 90mm; the process of the finishing process is: before and after Male and female thread processing, surface finishing, fine grinding and straightening;

[0040] Step 2. Put the finished titanium alloy electrode rod into the dynamic seal of the plasma rotary electrode atomization powder making equipment in step 1, and vacuum the plasma rotary electrode atomization powder making equipment to atomize the plasma rotary electrode The vacuum degree in the milling equipment is 0.9×10 -3 Pa; the dynamic seal adopts a ball bearing structure, and the sealing ring of the dynamic seal is made of polyurethane;

[0041] Step 3. Introduce the mixed gas into the plasma rotary electrode atomization powder making equipment after vacuuming in step 2, and then st...

Embodiment 3

[0045] This embodiment includes the following steps:

[0046] Step 1, finishing the titanium alloy electrode rod; the composition of the titanium alloy electrode rod is Ti-1Al-8V-5Fe, the tensile strength is 1448MPa, and the diameter is 70mm; the process of the finishing process is: before and after Male and female thread processing, surface finishing, fine grinding and straightening;

[0047] Step 2. Put the finished titanium alloy electrode rod into the dynamic seal of the plasma rotary electrode atomization powder making equipment in step 1, and vacuum the plasma rotary electrode atomization powder making equipment to atomize the plasma rotary electrode The vacuum degree in the milling equipment is 0.7×10 -3 Pa; the dynamic seal adopts a ball bearing structure, and the sealing ring of the dynamic seal is made of polyurethane;

[0048] Step 3. Introduce the mixed gas into the plasma rotary electrode atomization powder making equipment after vacuuming in step 2, and then st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com