Synthetic method and application of glycidyl methacrylate

A technology of glycidyl ester and methacrylic acid, which is applied in the field of synthesis of glycidyl methacrylate, can solve the problems of large recovery solvent loss and complicated process, and achieve the effects of increasing income, simple synthesis, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

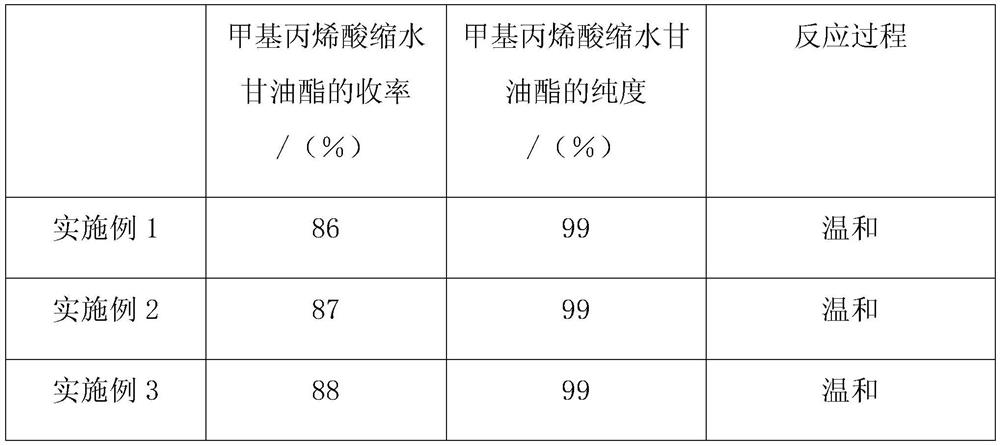

Embodiment 1

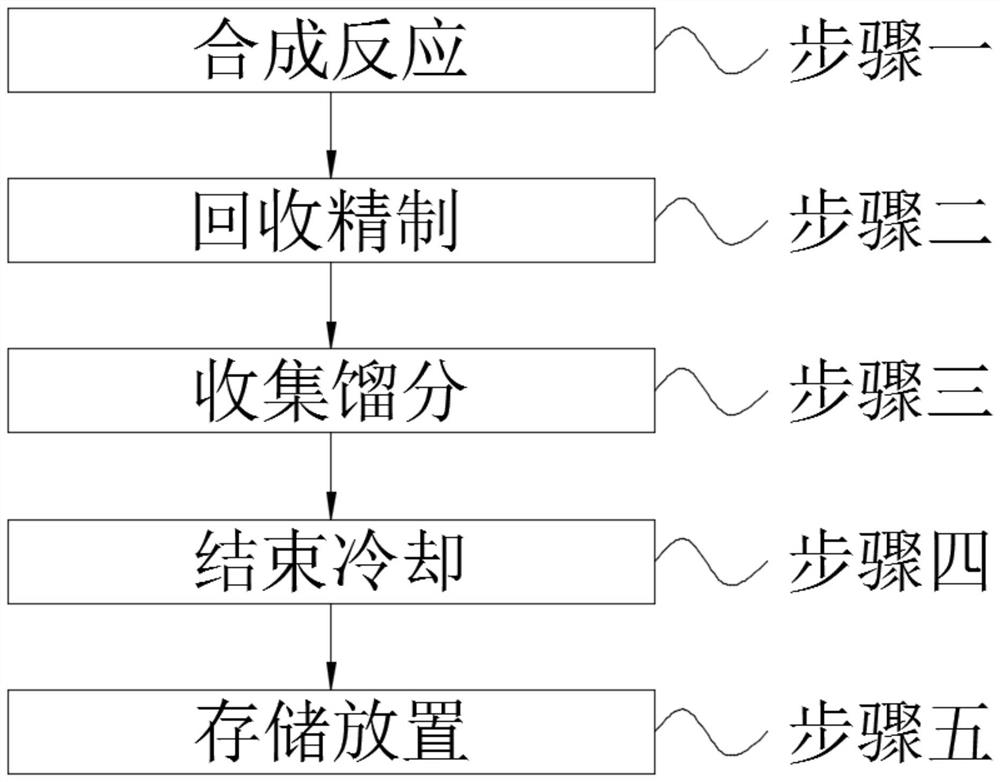

[0028] A synthesis method and application of glycidyl methacrylate, including step 1, synthesis reaction; step 2, recycling and refining; step 3, collecting fractions; step 4, finishing cooling; step 5, storing and placing;

[0029] Wherein in above-mentioned step one, synthetic reaction comprises the following steps:

[0030] 1) Manually prepare a 500L stirred tank, add 108kg sodium methacrylate, 270kg epichlorohydrin and 1.5kg PEG400, the molar ratio of epichlorohydrin to sodium methacrylate is 1.0:0.8-3.0, and the catalyst is methane 0.3-4% of sodium acrylate;

[0031] 2) Warm up to 60°C under stirring, keep warm for 5 hours, and the reaction is complete;

[0032] Wherein in above-mentioned step 2, recovering refining comprises the following steps:

[0033] 1) after the completion of the reaction, open the vacuum vacuum rectification to 10mmHg;

[0034] 2) Start the tower kettle to stir and heat up to reflux, adjust the reflux ratio;

[0035] Wherein in above-mentioned ...

Embodiment 2

[0041] A synthesis method and application of glycidyl methacrylate, including step 1, synthesis reaction; step 2, recycling and refining; step 3, collecting fractions; step 4, finishing cooling; step 5, storing and placing;

[0042] Wherein in above-mentioned step one, synthetic reaction comprises the following steps:

[0043] 1) Manually prepare a 500L stirred tank, add 108kg sodium methacrylate, 270kg epichlorohydrin and 1.5kg PEG800, the molar ratio of epichlorohydrin to sodium methacrylate is 1.0:0.8-3.0, and the catalyst is methyl 0.3-4% of sodium acrylate;

[0044] 2) Warm up to 60°C under stirring, keep warm for 5 hours, and the reaction is complete;

[0045] Wherein in above-mentioned step 2, recovering refining comprises the following steps:

[0046] 1) after the completion of the reaction, open the vacuum vacuum rectification to 10mmHg;

[0047] 2) Start the tower kettle to stir and heat up to reflux, adjust the reflux ratio;

[0048] Wherein in above-mentioned s...

Embodiment 3

[0054] A synthesis method and application of glycidyl methacrylate, including step 1, synthesis reaction; step 2, recycling and refining; step 3, collecting fractions; step 4, finishing cooling; step 5, storing and placing;

[0055] Wherein in above-mentioned step one, synthetic reaction comprises the following steps:

[0056] 1) Manually prepare a 500L stirred tank, add 108kg sodium methacrylate, 270kg epichlorohydrin and 1.5kg PEG1000, the molar ratio of epichlorohydrin to sodium methacrylate is 1.0:0.8-3.0, and the catalyst is methane 0.3-4% of sodium acrylate;

[0057] 2) Warm up to 60°C under stirring, keep warm for 5 hours, and the reaction is complete;

[0058] Wherein in above-mentioned step 2, recovering refining comprises the following steps:

[0059] 1) after the completion of the reaction, open the vacuum vacuum rectification to 10mmHg;

[0060]2) Start the tower kettle to stir and heat up to reflux, adjust the reflux ratio;

[0061] Wherein in above-mentioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com