Production method of high-purity spermine and co-production of high-purity trimethyl thiophosphate by-product

A technology of pure trimethyl thiophosphate and trimethyl thiophosphate, which is applied in the production field of high-purity spermine and co-production of high-purity trimethyl thiophosphate by-product, and can solve the problem of difficult removal of spermine, etc. problems, to achieve the effect of simple equipment and simplified process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

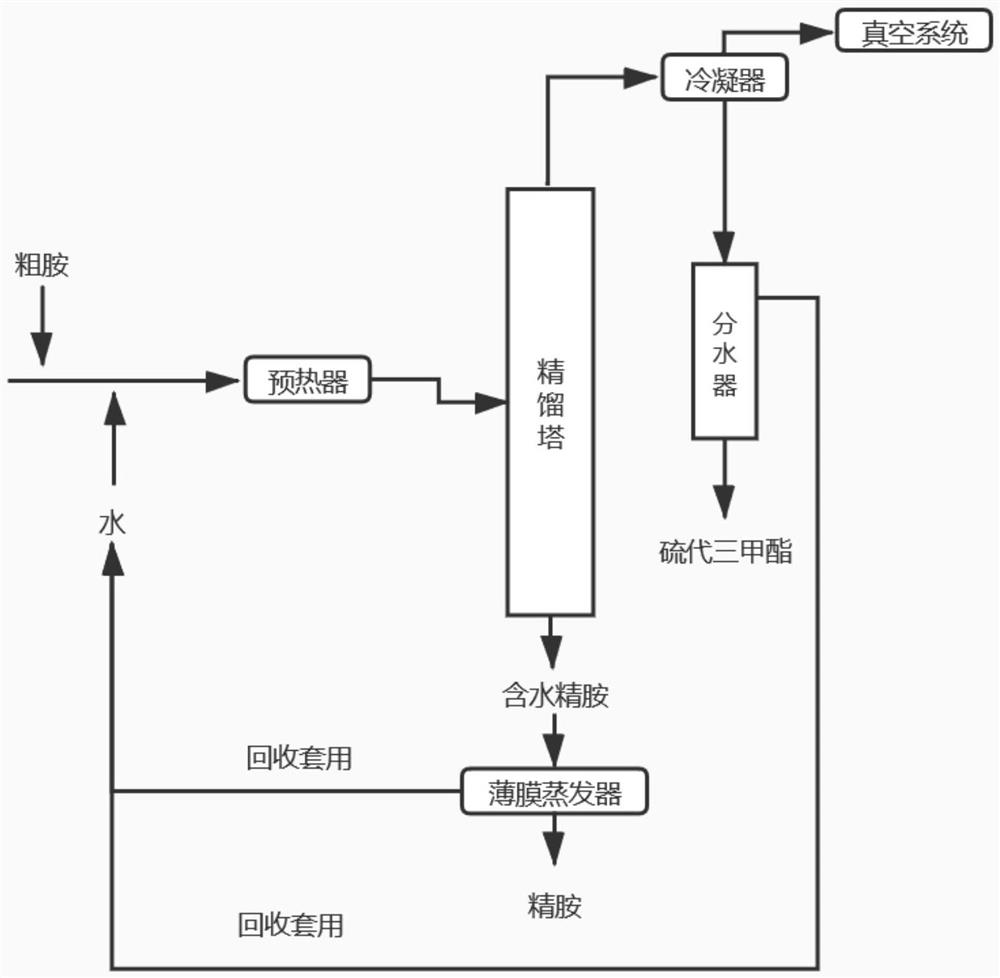

[0017] 1) After preheating the product crude amine from the trichloride to 0.2 times the heat exchanger to 40 ° C, the reduced pressure rectification column is entered from the middle of the reduced pressure rectification column. Among them, the composition of the crude amine is: 80 ~ 90% by weight of the aminethromine (O, O-dimethylthiometryamide), 5 to 10% by weight of trimethyl ester and 2 to 5 wt% water, wherein Trimethyl phosphate is by-product. The amine is then produced by ammonia, catalyzed isomer, acylated, and has the final product acetamin phosphorus.

[0018] 2) Set the top of the rectification tower to -0.009MPa, the top temperature of the tower is 30 ° C, the gas phase of the reduced pressure distillation is discharged from the top of the tower, and the colored condenser is condensed, and the condensate enters the die. After the moisture was separated, the upper separated water phase was used to obtain a top-level oil phase thiophosphate trimethyl ester content was 9...

Embodiment 2

[0021] 1) After preheating the product crude amine from the trichloride and 0.2 times the water to 50 ° C, the reduced pressure rectification column is entered from the middle of the reduced pressure rectification column. The composition of the crude amine is: 80 ~ 90 wt% of the amtroine (O, O-dimethylthylphopphipamide), 5 to 10% by weight of trimethyl phthalate and 2 to 5 wt% water;

[0022] 2) Set the rectification tower top pressure to -0.010 MPa, the top temperature of the tower is 40 ° C, the gas phase of the reduced pressure distillation is discharged from the top of the tower, and the colored condenser is condensed, and the condensate enters the water supply. After the moisture was separated, the upper separated water phase was used to recover, the above the lower oil phase phosphoric acid trimethyl ester was 97.6%, and the trimethyl phthalate recovery of thiophosphate was 78%;

[0023] 3) The liquid phase of the reduced pressure distillation is discharged from the bottom o...

Embodiment 3

[0025] 1) After preheating the product crude amine from the trichloride to 0.4 times the water through the heat exchanger to 50 ° C, the reduced pressure rectification column is entered from the middle of the reduced pressure rectification column. The composition of the crude amine is: 80 ~ 90 wt% of the amtroine (O, O-dimethylthylphopphipamide), 5 to 10% by weight of trimethyl phthalate and 2 to 5 wt% water;

[0026] 2) Set the top of the rectification tower to -0.015 MPa, the top temperature of the tower is 40 ° C, the gas phase of the reduced pressure distillation is discharged from the top of the tower, and the condensate is condensed, and the condensate enters the water supply. After the moisture was separated, the upper separated water phase recovery sleeve, the above-yielded lower oil phase thiophosphate is 97.6%, and the trimethyl phthalate recovery of thiophosphate is 80%;

[0027] 3) The liquid phase of the reduced pressure distillation is discharged from the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com