Signal transmission optical module

A signal transmission and optical module technology, applied in the field of optical communication, can solve the problem that the package thickness does not meet the market demand of ultra-thin products, and achieve the effect of reducing thickness, reducing signal loss and short optical path transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

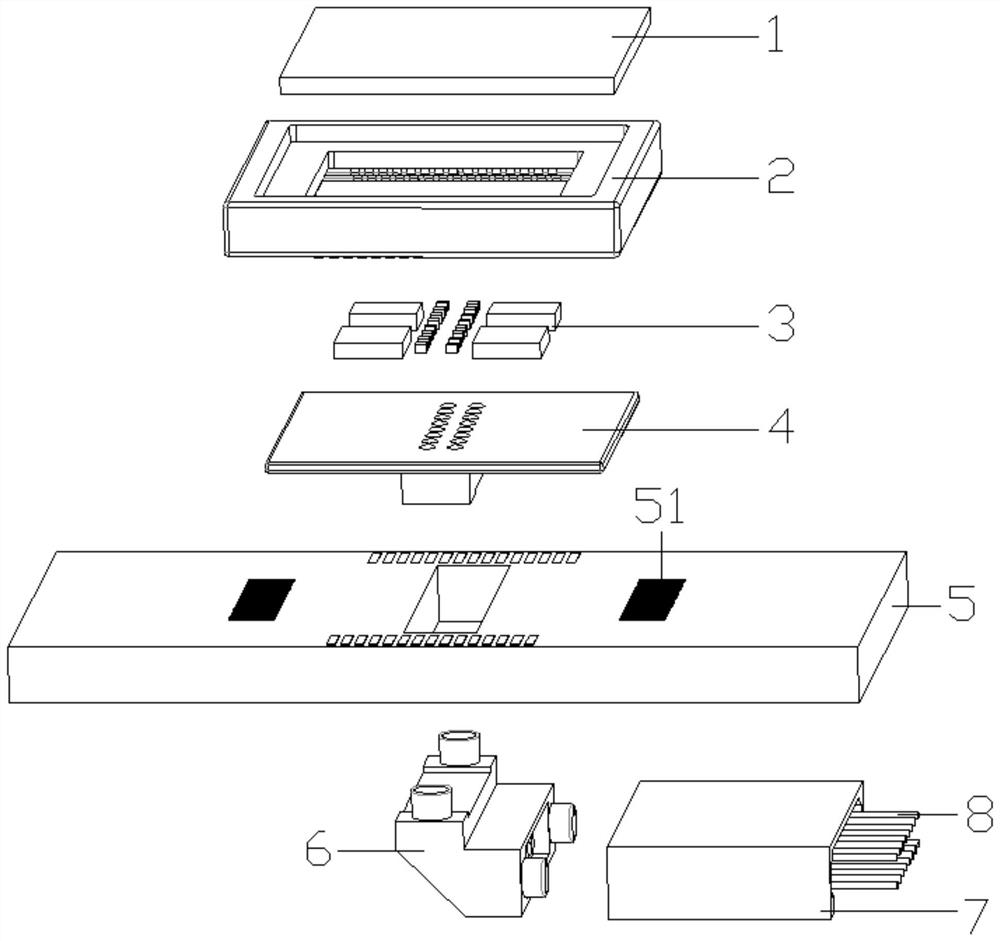

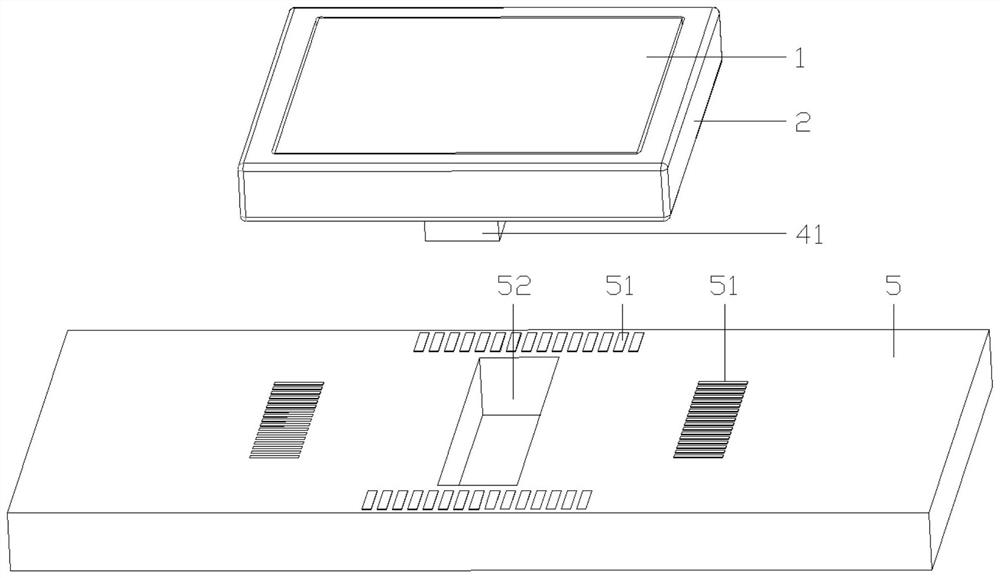

[0041] Such as Figure 9 As shown, the first lens module 4 is integrated with a first lens 9, and the optical fiber carrier 7 is integrated with a second lens 10. The light emitted by the photoelectric conversion chip 32 is collimated through the first lens 9 and passed through the second lens 10. The light received by the fiber group 8 is collimated by the second lens 10 and then focused onto the photoelectric conversion chip 32 by the first lens 9 . At this time, the fiber carrier 7 is perpendicular to the PCB board 5 .

no. 2 example

[0043] Such as Figure 8 As shown, the optical module also includes a second lens module 6, the lens area 41 is provided with a positioning hole 42, the second lens module 6 is assembled with the first lens module 4 through the positioning hole 42, and the first lens module 4 A first lens 9 is integrated on the top, and a 90-degree corner block 11 and a second lens 10 are integrated on the second lens module 6. The 90-degree corner block 11 is a right-angled triangular prism, and the planes of the first lens 9 and the second lens 10 are Respectively parallel to the two right-angled surfaces of the 90-degree corner block 11, so that the light collimated by the first lens 9 passes through the 90-degree corner block 11 and enters the second lens 10 after turning 90 degrees, and the light emitted by the photoelectric conversion chip 32 passes through the After the first lens 9 is collimated and turned by 90 degrees through the 90-degree corner block 11, it is focused into the opti...

no. 3 example

[0045] Such as Figure 8 As shown, the optical module also includes a second lens module 6, the lens area 41 is provided with a positioning hole 42, the second lens module 6 is assembled with the first lens module 4 through the positioning hole 42, and the first lens module 4 A first lens 9 is integrated on the top, a 90-degree corner block 11 is integrated on the second lens module 6, a second lens 10 is integrated on the optical fiber carrier 7, the 90-degree corner block 11 is a right-angled triangular prism, and the first lens 9 and The planes of the second lens 10 are respectively parallel to the two right-angle surfaces of the 90-degree corner block 11, so that the light collimated through the first lens 9 enters the second lens 10 after turning 90 degrees through the 90-degree corner block 11. This implementation Compared with the second embodiment, only the second lens 10 is separated from the second lens module 6, and the transmission principle of the optical path is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com