Iron-nitrogen co-doped carbon and MXene compound as well as preparation method and application thereof

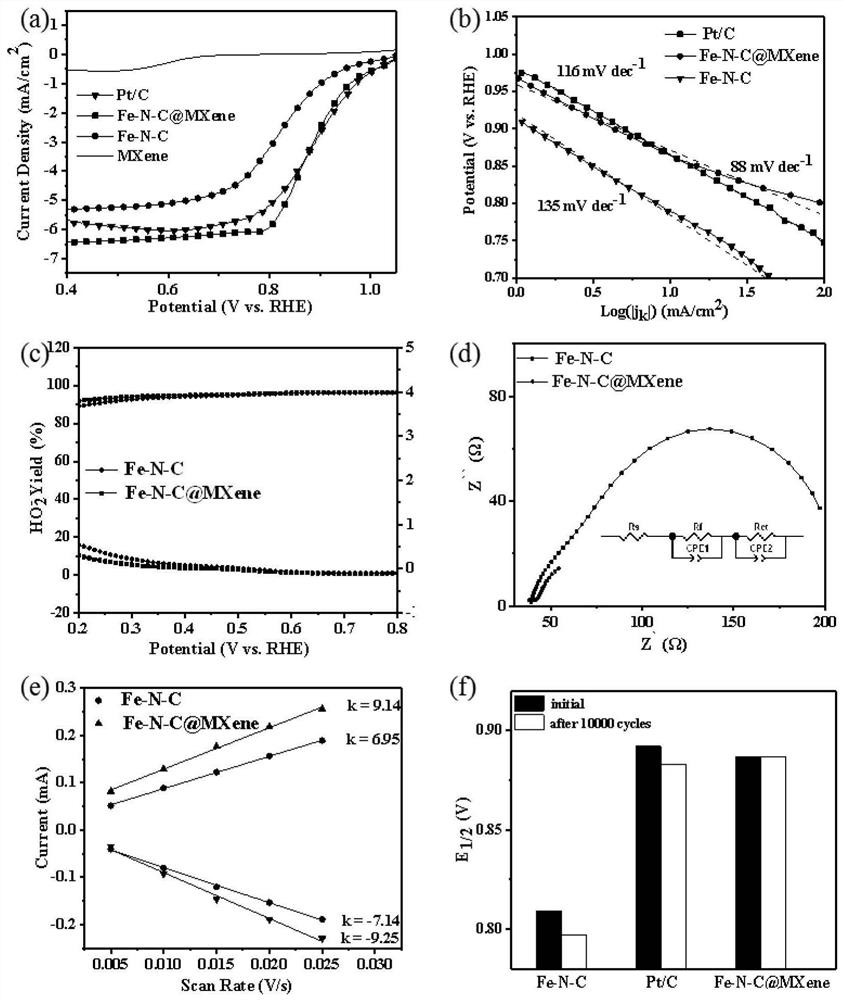

A technology of co-doping and composites, applied in electrical components, battery electrodes, circuits, etc., can solve problems such as poor conductivity and stability, achieve small electrochemical impedance, excellent ORR catalytic activity and stability, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

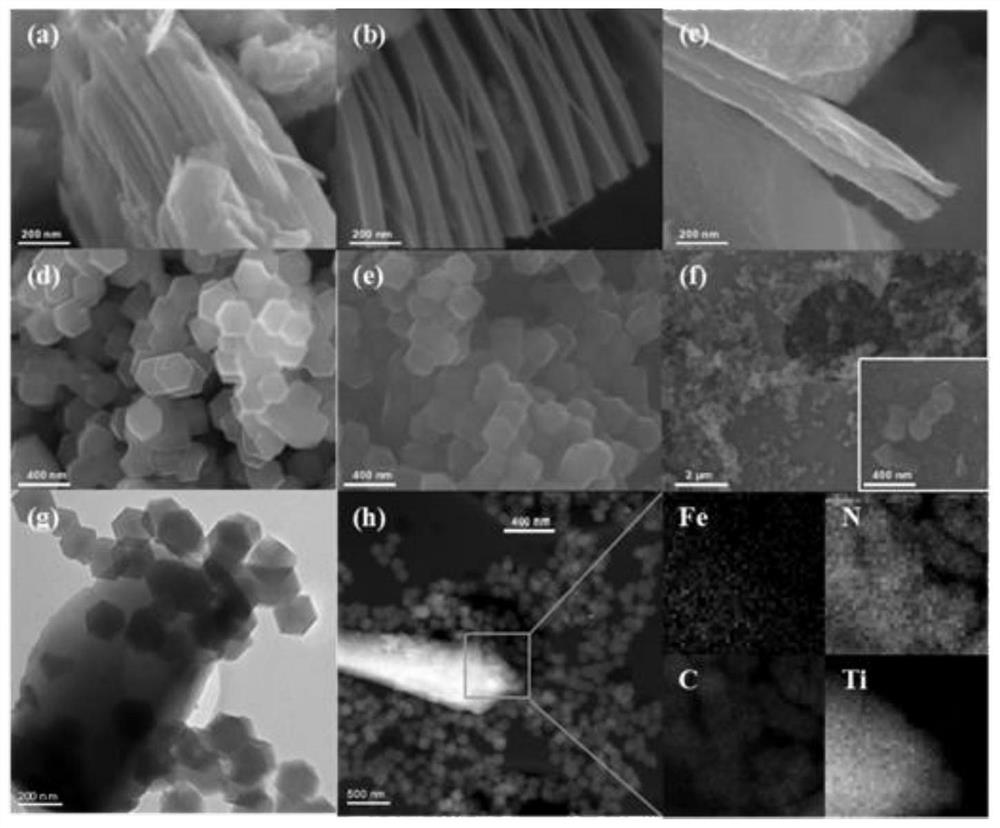

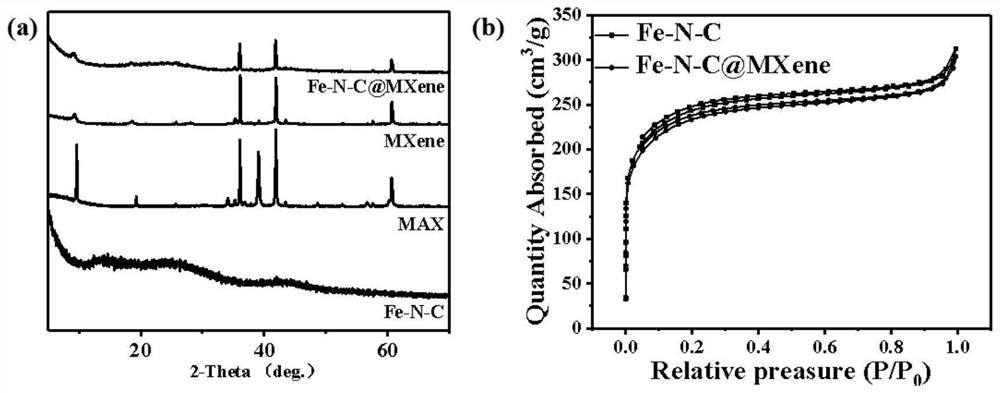

[0033] 1. Few layers of Ti 3 C 2 T x Preparation method: Weigh 0.5g Ti 3 AlC 2, uniformly dispersed in 20mL 40% HF solution, stirred at room temperature for 72h. After the reaction, the product was collected by centrifugation, washed repeatedly with deionized water, and centrifuged until the pH of the solution was close to 7. The resulting product was dried under vacuum at 60 °C for 12 h to obtain laminated Ti 3 C 2 T x . Then the obtained black powder was dispersed in deionized water, ultrasonically treated for 12 h, and the product was collected by centrifugation to obtain a few-layer Ti 3 C 2 T x (2-3 floors).

[0034] 2. 6.5g of 2-methylimidazole was dissolved in 80mL of methanol, which was recorded as solution A; 3g of zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 O) with 0.4g iron acetylacetonate (Fe(acac) 3 ) was dissolved in 40mL of methanol, recorded as solution B. Solution A and solution B were mixed, stirred at room temperature for 24 h, then suction f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com