Quick-drying sports towel

A quick-drying and moving technology, applied in physical treatment, cellulose plastic material layered products, and liquid repellent fibers, etc., can solve the problem of unfriendly environment, non-biodegradable chemical fiber raw materials, and natural fiber towels that cannot be hygroscopic and durable. Quick drying and other problems, to achieve the effect of excellent antibacterial effect, excellent biodegradability, excellent moisture wicking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

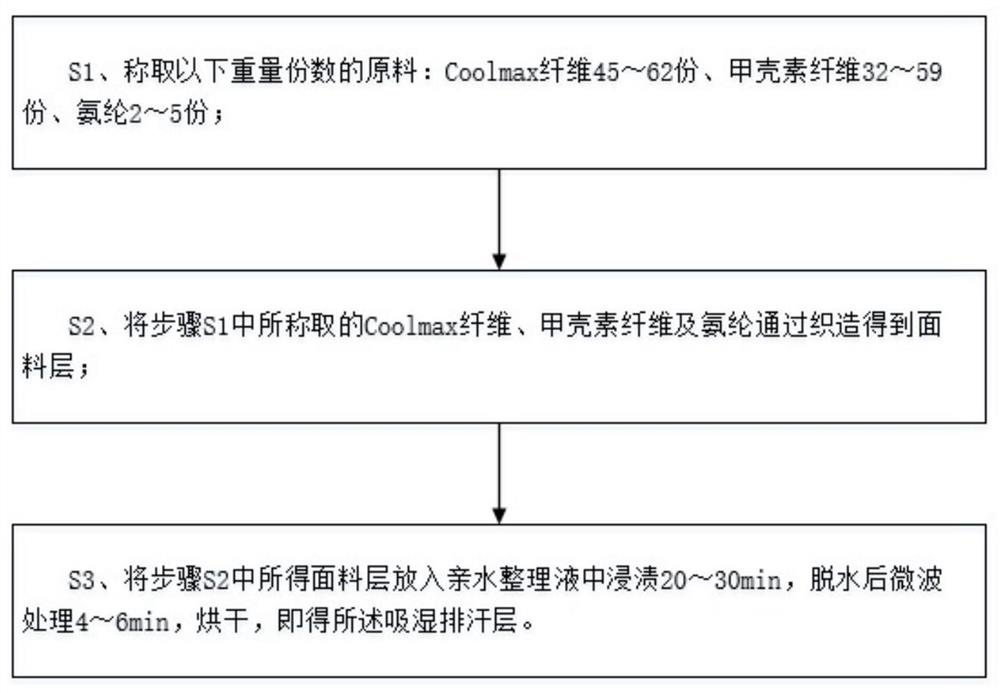

Method used

Image

Examples

Embodiment 1

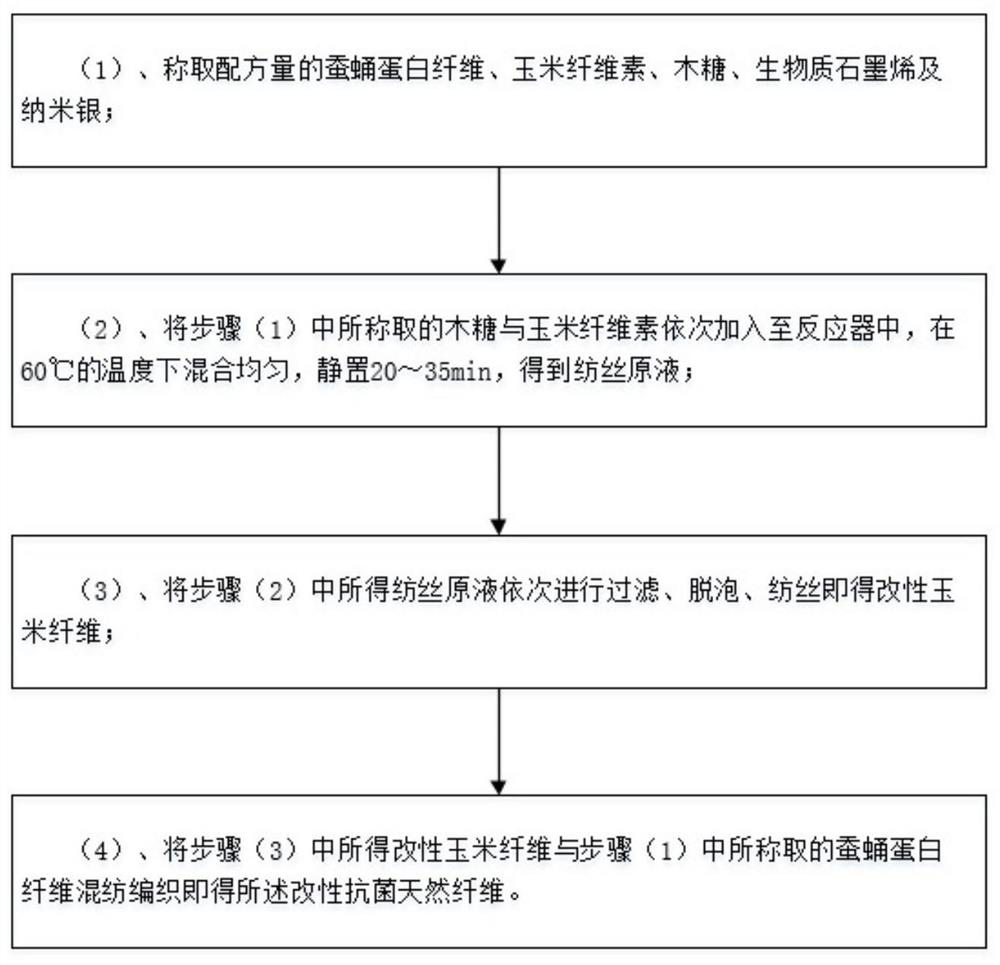

[0038] refer to image 3 As shown, a modified antibacterial natural fiber is made of the following raw materials: silkworm chrysalis protein fiber 45g, corn cellulose 100g, xylose 2g, biomass graphene 0.1g, nano silver 0.02g.

[0039] The preparation method of above-mentioned modified antibacterial natural fiber comprises the following steps:

[0040] (1), silkworm chrysalis protein fiber, corn cellulose, xylose, biomass graphene and nano-silver that take formula quantity;

[0041] (2), adding the xylose and corn cellulose weighed in the step (1) into the reactor in sequence, mixing evenly at a temperature of 60° C., and standing for 21 minutes to obtain the spinning stock solution;

[0042] (3), the spinning stock solution obtained in the step (2) is successively filtered, defoamed, and spun to obtain the modified corn fiber;

[0043](4), blending and weaving the modified corn fiber obtained in the step (3) with the silkworm chrysalis protein fiber weighed in the step (1) t...

Embodiment 2

[0045] refer to image 3 As shown, a modified antibacterial natural fiber is made of the following raw materials: silkworm chrysalis protein fiber 89g, corn cellulose 100g, xylose 8.3g, biomass graphene 5g, nano silver 0.15g.

[0046] The preparation method of above-mentioned modified antibacterial natural fiber comprises the following steps:

[0047] (1), silkworm chrysalis protein fiber, corn cellulose, xylose, biomass graphene and nano-silver that take formula quantity;

[0048] (2), adding the xylose and corn cellulose weighed in the step (1) into the reactor successively, mixing evenly at a temperature of 60° C., and standing for 35 minutes to obtain the spinning stock solution;

[0049] (3), the spinning stock solution obtained in the step (2) is successively filtered, defoamed, and spun to obtain the modified corn fiber;

[0050] (4), blending and weaving the modified corn fiber obtained in the step (3) with the silkworm chrysalis protein fiber weighed in the step (1)...

Embodiment 3

[0052] refer to image 3 As shown, a modified antibacterial natural fiber is made of the following raw materials: silkworm chrysalis protein fiber 85g, corn cellulose 100g, xylose 3g, biomass graphene 1.4g, nano silver 0.08g.

[0053] The preparation method of above-mentioned modified antibacterial natural fiber comprises the following steps:

[0054] (1), silkworm chrysalis protein fiber, corn cellulose, xylose, biomass graphene and nano-silver that take formula quantity;

[0055] (2) Add the xylose and corn cellulose weighed in the step (1) into the reactor in sequence, mix evenly at a temperature of 60° C., and let stand for 20 to 35 minutes to obtain the spinning stock solution;

[0056] (3), the spinning stock solution obtained in the step (2) is successively filtered, defoamed, and spun to obtain the modified corn fiber;

[0057] (4), blending and weaving the modified corn fiber obtained in the step (3) with the silkworm chrysalis protein fiber weighed in the step (1) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com