Waste liquid heavy metal treatment and recovery equipment and process

A recovery equipment and heavy metal technology, applied in the direction of filtration treatment, special treatment targets, multi-stage water treatment, etc., can solve the problems of heavy metal separation, low recovery efficiency, high energy consumption, etc., achieve stable filtration effect, improve recovery efficiency, Ease of reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

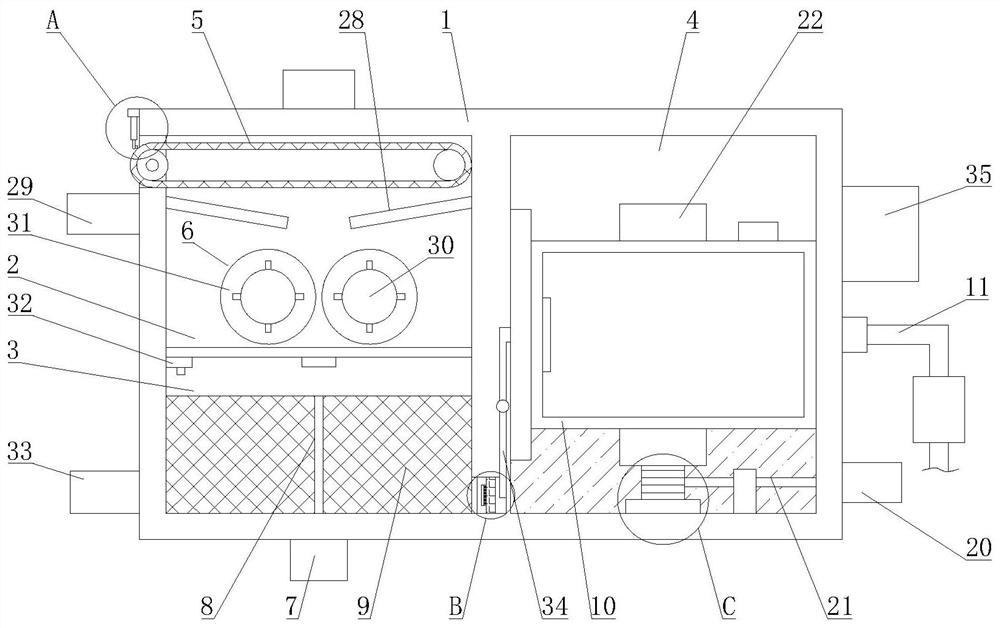

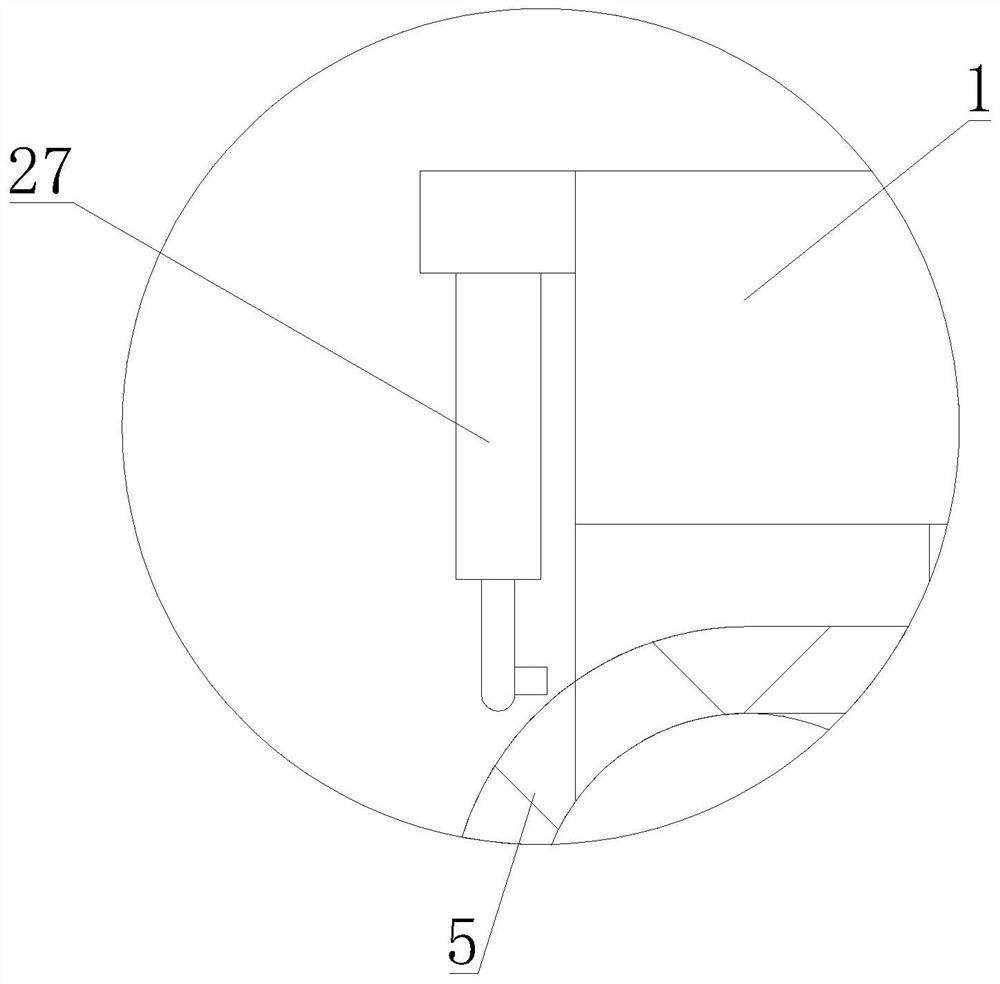

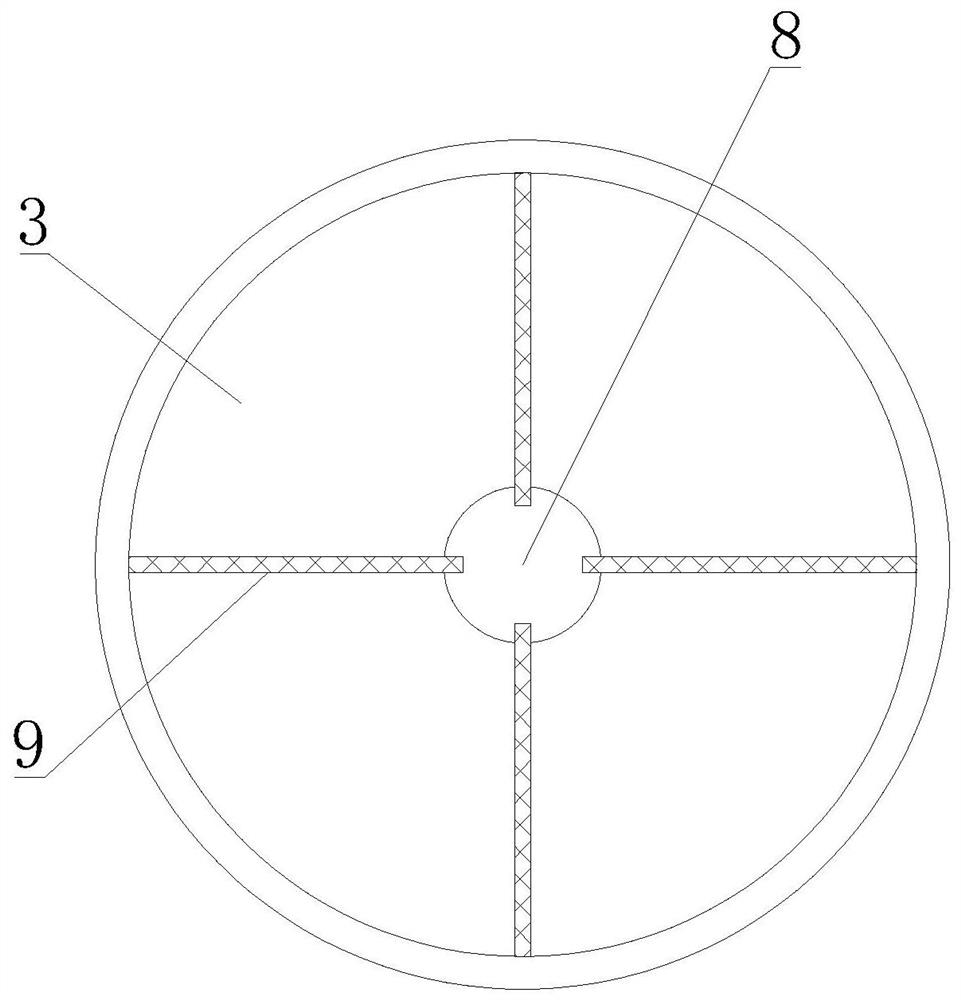

[0042] Such as Figure 1-6As shown, a waste liquid heavy metal treatment and recovery device proposed by the present invention includes a housing 1, a filter belt 5, a metal adsorption roller 6, a concentration cylinder 10, a water pipe 34, a condenser 11, a heating element and a vacuum device 35; The inside of the body 1 is provided with a recovery chamber 2, a treatment chamber 3 and a concentration chamber 4; the recovery chamber 2 is arranged above the treatment chamber 3; the concentration chamber 4 is arranged on one side of the treatment chamber 3, and communicates with it through a water pipe 34; 5 is arranged below the water inlet of the recovery chamber 2; the metal adsorption roller 6 is arranged below the filter belt 5; the concentrating cylinder 10 is rotated and arranged in the concentrating chamber 4, and is heated by a heating element and depressurized by a vacuum device 35; the condenser 11 and The gas outlet end of the concentrator cylinder 10 communicates; a...

Embodiment 2

[0051] Such as figure 1 , 7 As shown, on the basis of the foregoing embodiments, the present invention is provided with a fourth drive motor 20, a transmission shaft 21, a first gear 22 and a second gear 23 in the concentrating chamber 4; the first gear 22 is keyed to the outer wall of the concentrating cylinder 10 ; The transmission shaft 21 driven by the fourth drive motor 20 is rotated and installed in the concentration chamber 4 , and the main shaft is keyed to the second gear 23 ; the second gear 23 is meshed with the first gear 22 .

[0052] In an optional embodiment, the inner wall of the concentration chamber 4 is provided with a support seat 24; the support seat 24 is located on the side of the second gear 23 away from the first gear 22, and the support seat 24 is provided with a support groove 26; the support groove 26 is provided with a third gear 25 for rotation; the third gear 25 is meshed with the second gear 23 .

[0053] In the present invention, the first ge...

Embodiment 3

[0055] The present invention also proposes a waste liquid heavy metal treatment and recovery process, including the device in the above embodiment, the steps are as follows:

[0056] S1. Pour the waste liquid into the recovery chamber 2. The filter belt 5 filters out the large-volume metal particles in the waste liquid. The filter belt 5 rotates to move the metal particles to the outside of the housing 1. Under the impact of the high-pressure spray gun 27, the metal moves To collection box 29, filter belt 5 is cleaned and dredged simultaneously;

[0057] S2, the waste liquid falls on the metal adsorption roller 6 along the material guide plate 28, controls the magnetism of the metal adsorption roller 6, and absorbs and recycles the small-volume metal particles in the waste liquid;

[0058] S3, waste water enters the treatment chamber 3, and purifiers (acid-base regulators, sedimentation agents and complexing agents) are added to the treatment chamber, and through the action of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com