Self-heat-absorption anti-icing easy-deicing coating for power grid overhead ground wire and preparation method thereof

An overhead ground wire, anti-icing technology, applied in the direction of polyether coating, coating, etc., can solve the problems of insufficient safety distance of wires, affecting the normal operation of the line, galloping discharge, etc., to achieve easy fall off, enhance the ability of hydrophobic and anti-fouling , the effect of preventing freezing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

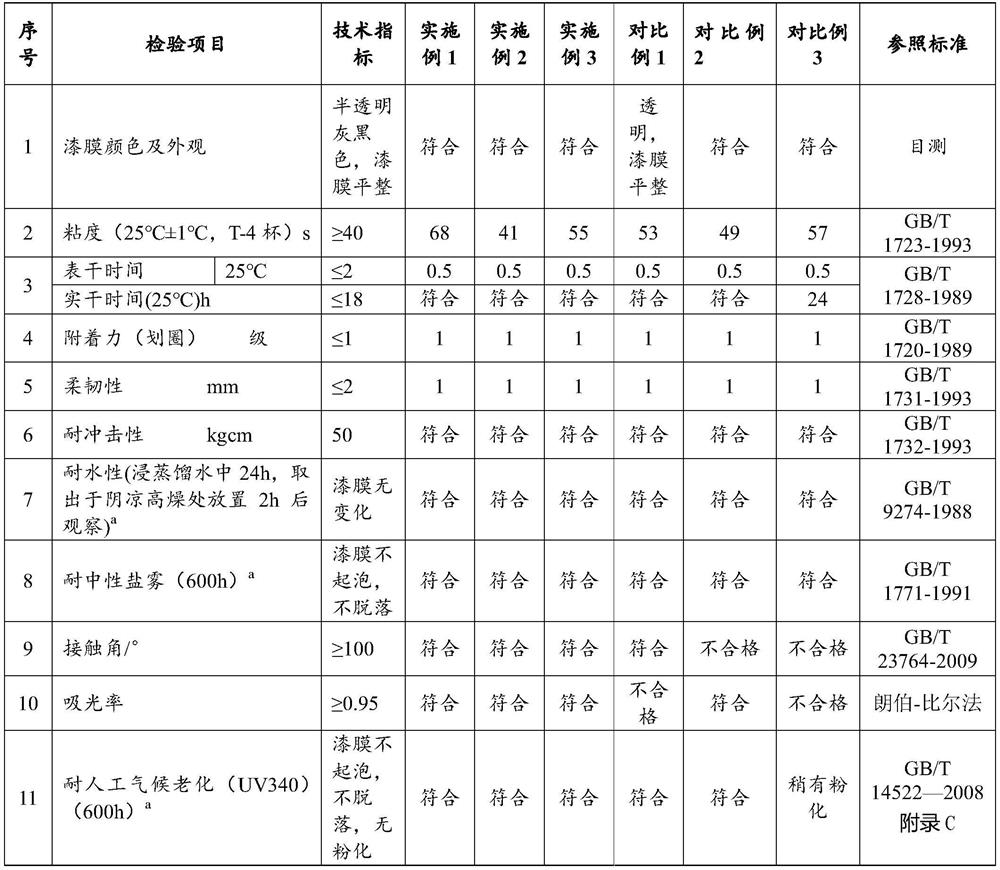

Examples

preparation example Construction

[0031] Another aspect of the embodiment of the present invention provides the preparation method of the aforementioned self-absorbing heat-removing easy-to-deicing coating for the overhead ground wire of the power grid, which includes: silicone modified resin, polytetrafluoroethylene micropowder, self-absorbing heat pigment, perfluorinated Polyether, butyl acetate, and xylene are mixed and stirred evenly, and the fineness of grinding is 20um, and then the viscosity of the obtained mixture is adjusted with xylene to obtain the self-absorbing heat-absorbing and easy-to-deicing coating for the overhead ground wire of the power grid.

[0032] Further, the stirring time is 20-30 min, and the rotation speed is 2000-4000 r / min.

[0033] Further, the viscosity of the obtained mixture was adjusted to T-4 cup for 40-70s with xylene.

[0034] Another aspect of the embodiments of the present invention provides a self-absorbing heat-easy deicing coating for power grid overhead ground wires, ...

Embodiment 1

[0049] According to the mass percentage (if not specified below, it refers to the mass percentage content of each component in the self-absorbing heat and easy deicing coating for overhead ground wires of the power grid), respectively, take the Siloke Silicon 45% of PFPE resin and 10% of butyl acetate were added to the mixing pot and stirred at a speed of 4000r / min for 5 minutes. While stirring, continue to add 20% of polytetrafluoroethylene micropowder, 15% of self-endothermic pigment, and 1.1% of perfluoropolyether. , xylene 8.9%, continue to stir at the same speed for 10min, grind until the fineness meets the requirements, adjust the viscosity to T-4 cup 40-70S with xylene, filter to obtain the power grid overhead ground wire with self-absorbing heat and easy deicing Coating component A and component B are made of N3390 trimer 100%, and components A and B are mixed according to -NCO:-OH=1:1 (mass ratio) and cured to form an overhead ground wire of the power grid. Floor.

Embodiment 2

[0051] According to the mass percentage (if not specified below, it refers to the mass percentage content of each component in the self-absorbing heat and easy deicing coating for overhead ground wires of the power grid), respectively, take the Siloke Silicon 52% of PFPE resin and 22% of butyl acetate were added to the mixing pot and stirred at a speed of 4000r / min for 5 minutes. While stirring, 14% of polytetrafluoroethylene micropowder, 5% of self-endothermic pigment, and 2% of perfluoropolyether were added. , xylene 5%, continue to stir at the same speed for 10min, grind until the fineness meets the requirements, adjust the viscosity to T-4 cup 40-70S with xylene, filter to obtain the power grid overhead ground wire with self-absorbing heat and easy deicing Coating component A and component B are made of N3390 trimer 100%, and components A and B are mixed according to -NCO:-OH=1:1 (mass ratio) and cured to form an overhead ground wire of the power grid. Floor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Contact angle | aaaaa | aaaaa |

| Roll angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com