Anode layer ion source reducing sputtering pollution

An ion source and anode layer technology, applied in sputtering plating, ion implantation plating, coating, etc., can solve the problems of poor processing, easy cracking, and increased cost of graphite, and achieve improved cooling effect and uniformity , the effect of reducing sputtering pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

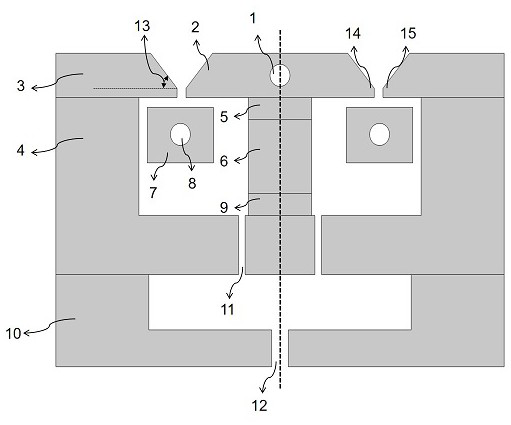

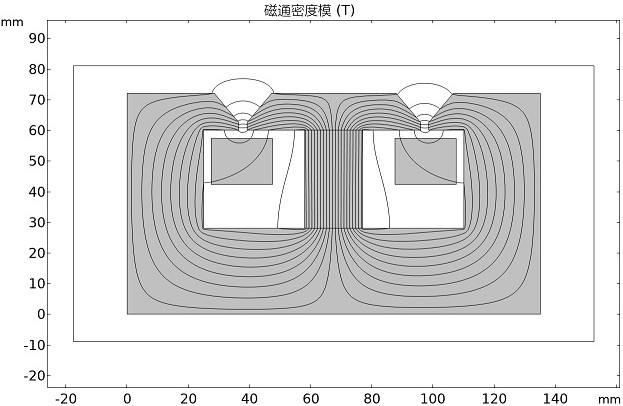

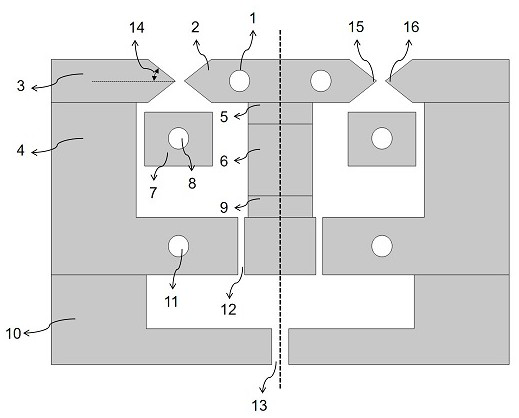

[0028] In order to reduce the sputtering pollution of the ion source of the anode layer and prolong the maintenance time of the ion source of the anode layer, the present invention simulates and calculates the magnetic field distribution of the discharge chamber formed by the inner cathode ring, the outer cathode ring and the anode ring through finite element numerical calculation, and provides a Anode layer ion source with high magnetic mirror ratio. Such as image 3As shown, its main structure includes: anode ring 7, cathode inner ring 2, cathode outer ring 3, permanent magnet 6, yoke 4, gas supply system (12, 13), cooling liquid inlet / outlet pipeline of the anode ring 8. The inlet / outlet pipe 1 for the cathode inner ring cooling liquid, and the inlet / outlet pipe 11 for the yoke cooling liquid. The cathode inner ring 2 is installed opposite to the cathode outer ring 3, and the gap between them is kept constant along the length direction of the ion source. The anode ring 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com