Spindle-shaped MXene-carbon nanotube two-dimensional film as well as preparation method and application thereof

A technology of carbon nanotubes and single-walled carbon nanotubes, applied in the field of spindle-shaped MXene-carbon nanotube two-dimensional membranes and its preparation, can solve the problems of unstable anti-pollution ability, inability to be widely used, and low water flux , to achieve high selectivity, wide applicability and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

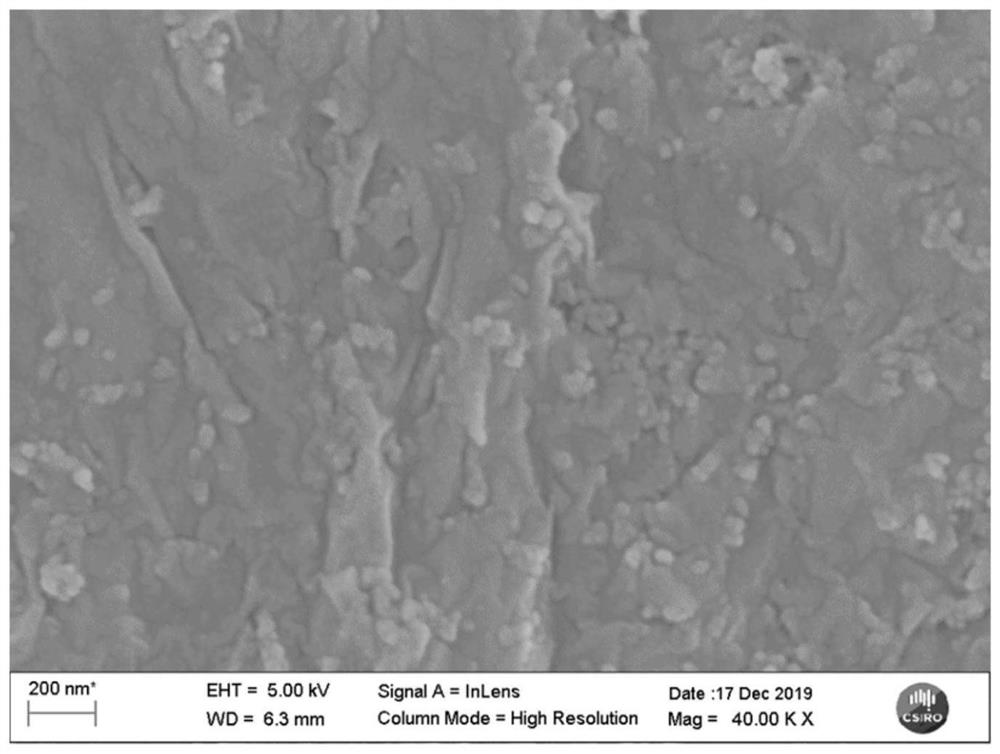

[0033] A kind of spindle-shaped MXene-carbon nanotube two-dimensional membrane, comprises support layer and separation function layer, and described support layer is positioned at separation function layer below; A two-dimensional stacked membrane with spindle-shaped channels, the thickness of the separation functional layer is 500-1000 microns.

[0034] A preparation method for a spindle-shaped MXene-carbon nanotube two-dimensional film, comprising the following steps:

[0035] Step 1, mix 1g LiF powder with 30ml 6M hydrochloric acid solution, then mix 1g Ti 3 AlC 2 Slowly add the powder to the above mixed solution, stir at 35°C at a speed of 300rpm for 24 hours to obtain a dispersion A, then centrifuge the dispersion A, and then wash the precipitate with deionized water for 7 times until the pH is neutral. The precipitate was redispersed with deionized water, placed in a beaker, and after being stripped under ultrasonic conditions for 30 minutes, the above solution was cen...

Embodiment 2

[0044] A kind of spindle-shaped MXene-carbon nanotube two-dimensional film, comprises support layer and separation function layer, and described support layer is positioned at separation function layer below; Described separation function layer is formed by MXene and carboxylated multi-walled carbon nanotube A two-dimensional stacked membrane with spindle-shaped channels, the thickness of the separation functional layer is 500-1000 microns.

[0045] A preparation method for a spindle-shaped MXene-carbon nanotube two-dimensional film, comprising the following steps:

[0046] Step 1, 1.2 g LiF powder was mixed with 30 ml 9M hydrochloric acid solution, and then 1 g Ti 3 AlC 2 Add the powder slowly to the above mixed solution, stir at 35°C at a speed of 300rpm for 24 hours to obtain dispersion A, then centrifuge dispersion A, and then centrifuge and wash the precipitate with deionized water 7 times until the pH of the washing solution is neutral. The obtained precipitate was red...

Embodiment 3

[0055] A kind of spindle-shaped MXene-carbon nanotube two-dimensional film, comprises support layer and separation function layer, and described support layer is positioned at separation function layer below; Described separation function layer is formed by MXene and carboxylated multi-walled carbon nanotube A two-dimensional stacked membrane with spindle-shaped channels, the thickness of the separation functional layer is 500-1000 microns.

[0056] A preparation method for a spindle-shaped MXene-carbon nanotube two-dimensional film, comprising the following steps:

[0057] Step 1, 1.2 g LiF powder was mixed with 30 ml 9M hydrochloric acid solution, and then 1 g Ti 3 AlC 2 The powder was slowly added to the above mixed solution, stirred at 35°C at a speed of 300rpm for 24 hours to obtain dispersion A, and then the dispersion A was centrifuged, and then washed with deionized water for 7 times until the pH was neutral. The precipitate was redispersed with 100 mL deionized wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com