Alkali-resistant ultrafiltration membrane and preparation method thereof

An ultrafiltration membrane and alkali-resistant technology, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc. Prevent bacterial growth, good resistance to contamination and chemical attack, improve production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

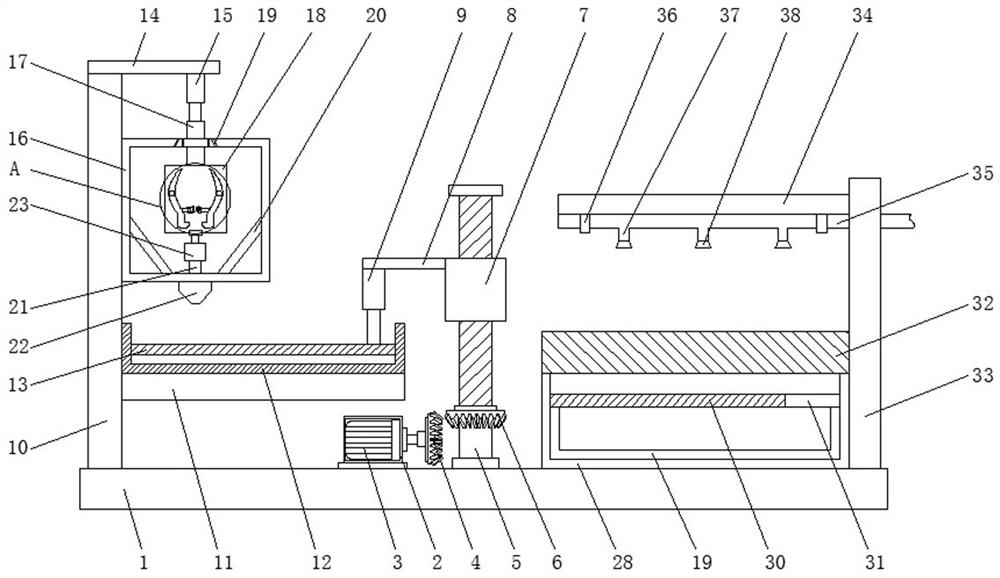

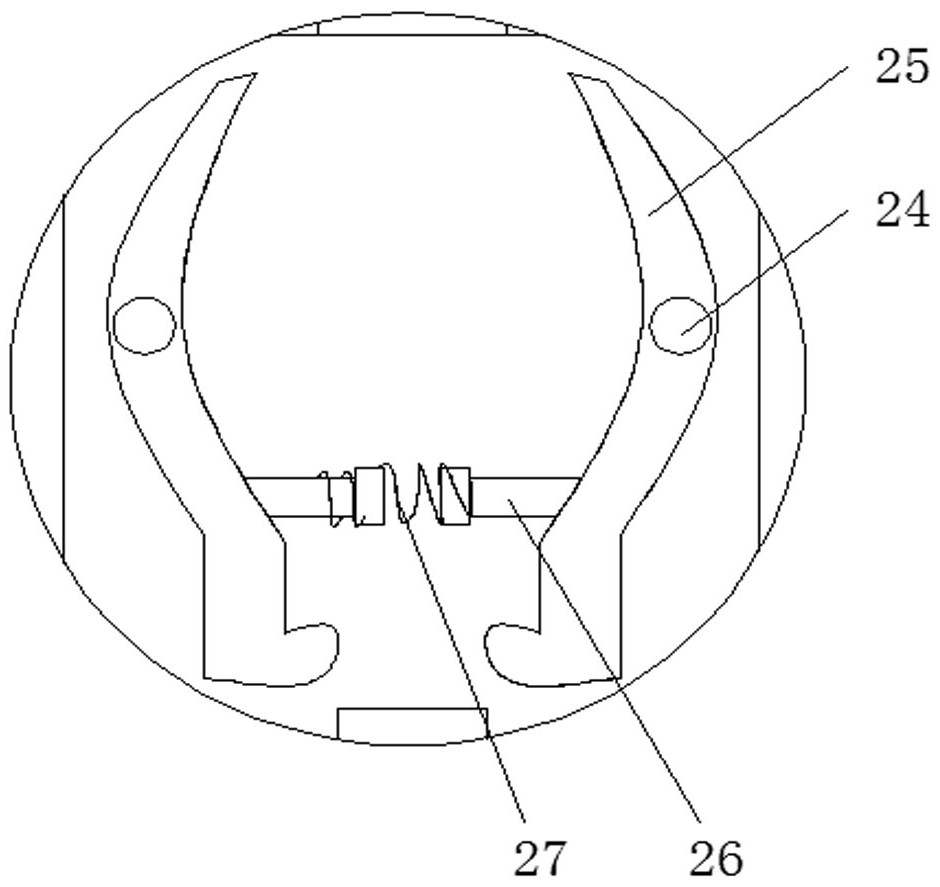

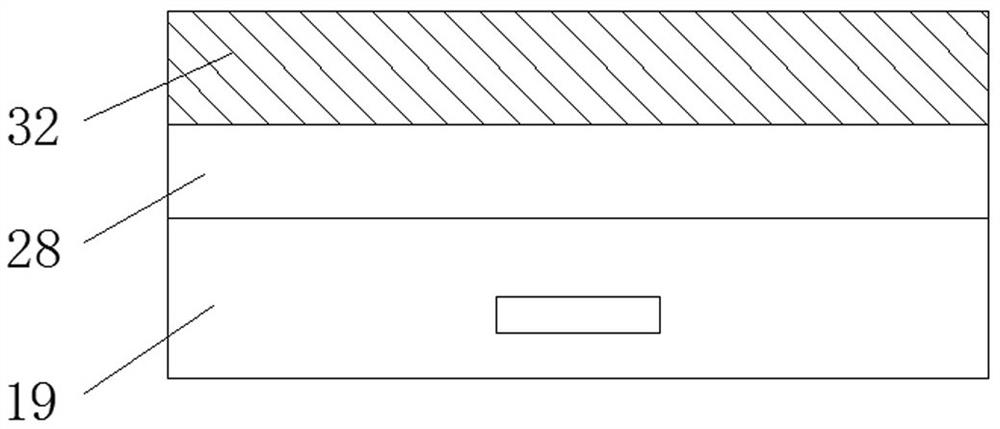

Image

Examples

Embodiment 1

[0042] An alkali-resistant ultrafiltration membrane, comprising the following raw materials in proportions by weight:

[0043] Polyvinyl chloride: 20 parts;

[0044] Polyvinylidene fluoride: 10 parts;

[0045] Additives: 5 parts;

[0046] Solvent: 70 parts.

[0047] The above-mentioned alkali-resistant ultrafiltration membrane and a preparation method thereof comprise the following steps:

[0048] Step 1, pretreating the membrane-making raw material;

[0049] Step 2, mixing the prepared raw materials with an organic solvent to obtain a casting solution;

[0050] S1, defoaming: the casting solution is placed in a defoaming tank, stirred for 1 hour at a temperature of 70°C, and left to stand for 24 hours after mixing evenly.

[0051] S2. Preparing fibrils: sending the fully defoamed mixed solution into the spinning machine, extruding with a spinneret to form hollow fibrils, and standing;

[0052] S3. After part of the solvent in the fibril evaporates, immerse in a 2% glyceri...

Embodiment 2

[0069] The difference between embodiment two and implementation one is:

[0070] An alkali-resistant ultrafiltration membrane, comprising the following components in parts by weight:

[0071] Polyvinyl chloride: 25 parts;

[0072] Polyvinylidene fluoride: 15 parts;

[0073] Additives: 10 parts;

[0074] Solvent: 80 parts.

[0075] In this embodiment, the fully dissolved casting solution needs to be degassed at a temperature of 50-100° C. for 5-9 hours.

[0076] In this example, the coating speed of the casting solution on the non-woven fabric is between 1 and 8 m / s

[0077] In this embodiment, polyvinyl chloride and polyvinylidene fluoride are mixed according to the formula amount, additives are added, and the mixed solution is heated to 70° C. to dissolve until the casting solution is uniform and transparent.

[0078] Others are the same as embodiment one.

Embodiment 3

[0080] Embodiment three is different from implementation one in that:

[0081] An alkali-resistant ultrafiltration membrane, comprising the following components in parts by weight:

[0082] Polyvinyl chloride: 15 parts;

[0083] Polyvinylidene fluoride: 5 parts;

[0084] Additives: 5 parts;

[0085] Solvent: 60 parts.

[0086] In this embodiment, the fully dissolved casting solution needs to be degassed at a temperature of 40-100°C for 5-8 hours.

[0087] In this example, the coating speed of the casting solution on the non-woven fabric is between 1 and 8 m / s

[0088] In this embodiment, polyvinyl chloride and polyvinylidene fluoride are mixed according to the formula amount, additives are added, and the mixed solution is heated to 50° C. to dissolve until the casting solution is uniform and transparent.

[0089] Others are the same as embodiment one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com