A kind of preparation method of wafer locking ring

A locking ring and wafer technology, which is used in manufacturing tools, heat treatment equipment, metal processing equipment, etc., can solve the problem that the flatness is not easy to control, and achieve the effect of ensuring the flatness, preventing large deformation, and ensuring the flatness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

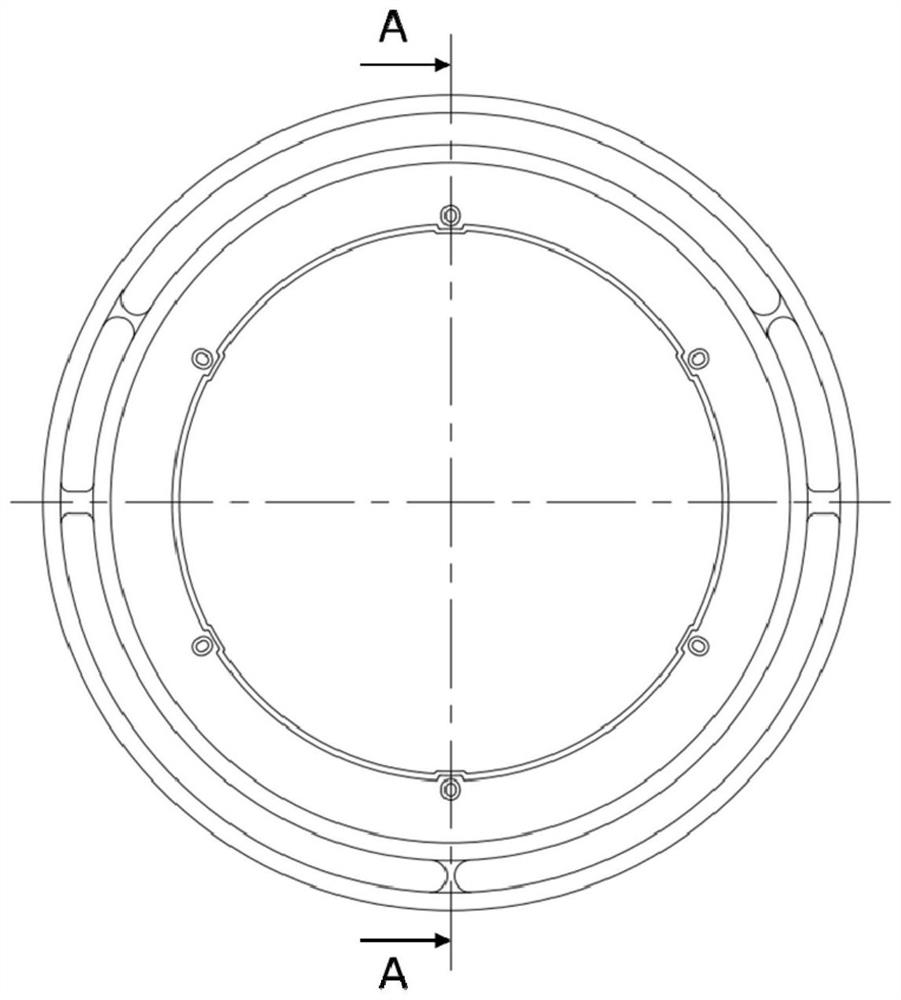

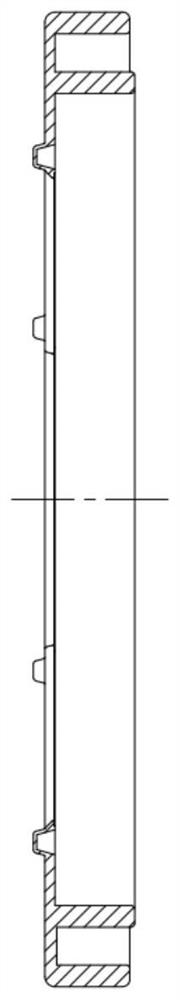

Image

Examples

preparation example Construction

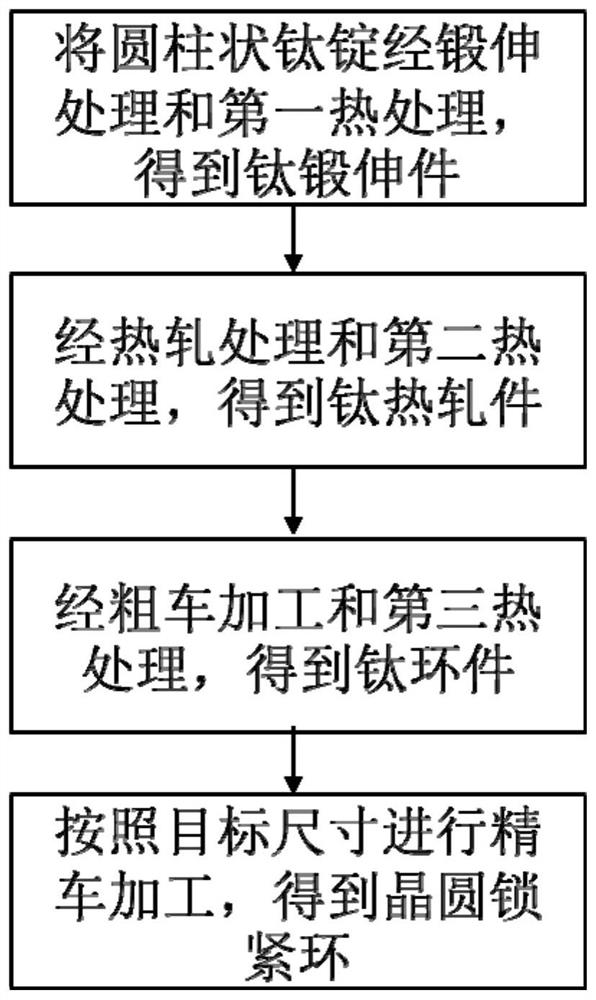

[0068] like image 3 As shown, the preparation method of the wafer locking ring of the present invention comprises the following steps:

[0069] (1) carrying out forging and drawing treatment of cylindrical titanium ingot, then carrying out the first heat treatment to obtain titanium forging and drawing parts;

[0070] (2) hot-rolling the titanium forgings described in step (1), and then performing the second heat treatment to obtain titanium hot-rolling;

[0071] (3) hollow out the central part of the titanium hot-rolled piece described in step (2) through rough turning, and then carry out the third heat treatment to obtain the titanium ring piece;

[0072] (4) Finishing the titanium ring in step (3) according to the target size to obtain a wafer locking ring.

Embodiment 1

[0074] The present embodiment provides a preparation method of a wafer locking ring, and the preparation method includes the following steps:

[0075] (1) Prepare a cylindrical titanium ingot with a purity of 99.9%, a diameter of 180 mm and a length of 120 mm, and carry out forging treatment at 950°C. Carry out upsetting according to the upsetting and forging ratio of 2.22, repeat 2 times and then water-cool, then carry out the first heat treatment at 650 ° C for 120 min, and obtain titanium forgings through air cooling;

[0076] (1') The titanium forging in step (1) is subjected to re-forging treatment at 800°C, and each re-forging treatment is first drawn and elongated according to the drawing and forging ratio of 2, and then according to the upsetting and forging ratio. Upsetting was carried out for 2.22, repeated 2 times and then water-cooled, and then the fourth heat treatment was carried out at 650 ° C for 120 min to obtain titanium forgings again;

[0077] (2) The tita...

Embodiment 2

[0081] The present embodiment provides a preparation method of a wafer locking ring, and the preparation method includes the following steps:

[0082] (1) Prepare a cylindrical titanium ingot with a purity of 99.9%, a diameter of 150 mm and a length of 150 mm, and carry out forging treatment at 900 °C. Carry out upsetting according to the upsetting and forging ratio of 2.5, repeat 3 times and then water-cool, then carry out the first heat treatment at 600 ° C for 150 min, and obtain titanium forgings through air cooling;

[0083] (1') The titanium forging in step (1) is subjected to re-forging treatment at 750°C, and each re-forging treatment is firstly drawn according to the drawing and forging ratio of 2, and then according to the upsetting and forging ratio. Upsetting was carried out for 2.5, repeated 3 times after water cooling, and then the fourth heat treatment was carried out at 600 ° C for 150 min to obtain a titanium forging again;

[0084] (2) The titanium re-forgin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com