A kind of antibacterial fresh-keeping film and preparation technology thereof

A preparation process and technology of plastic wrap, applied in the field of antibacterial plastic wrap and its preparation technology, can solve the problems of moldy microorganisms in food, plastic wrap does not have antibacterial effect, plastic wrap does not have antibacterial effect, etc., and achieves the improvement of bactericidal and antibacterial effect , Improve the antibacterial properties and elongation at break, and improve the antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

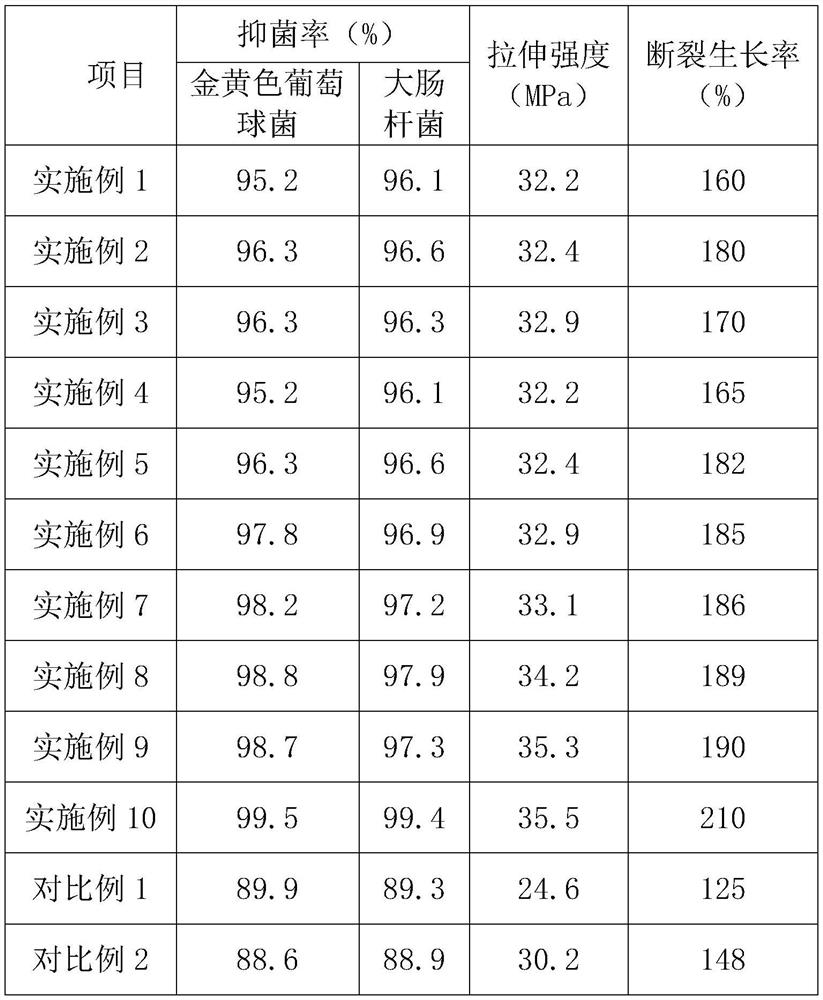

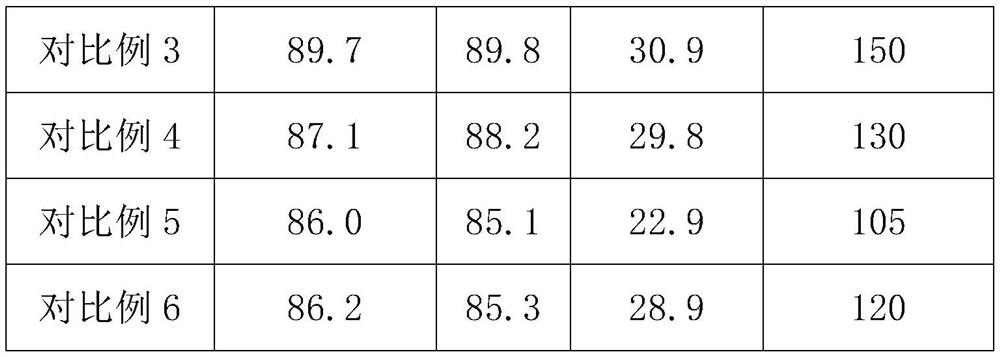

Examples

Embodiment 1

[0056] Antibacterial preservation film is produced in accordance with the preparation process of the present application:

[0057] Each will 2kg low-density high pressure polyethylene, 96kg high-density low-voltage polyethylene, 1kg silver silicate, 3kg hydroxybenzylpropyl, 1kg china, 0.4kg lactic acid, bacteria, 6kg edible gelatin, 0.5kg water talc, 0.3 Kg activated carbon (1000 mesh) was mixed at a temperature of 200 ° C for 20 min to form a first base layer mixture and a second base mixture;

[0058] Each will 2kg low density high pressure polyethylene, 96kg high-density low-voltage polyethylene, 1kg silver silicate, 2 kg ethyl vanilla, 1kg china, 3kg edible gelatin, 0.3kg water talc, 0.1kg activated carbon (1250) 15 min was mixed at a temperature of 240 ° C to form a first stabilizing layer mixture and a second stable layer mixture;

[0059] 94kg high-density low-voltage polyethylene, 6kg silver silicate, 2 kg edible gelatin, 0.3 kg of water talc, 0.1 kg of activated carbon (1...

Embodiment 2

[0062] Antibacterial preservation film is produced in accordance with the preparation process of the present application:

[0063] Each will be 10kg low-density high pressure polyethylene, 85kg high-density low-voltage polyethylene, 6kg silver silicate, 2kg hydroxybenzyl, 3kg chrose, 0.2kg lactic acid-chain bacteria, 8kg edible gelatin, 0.2kg Water Tie, 0.1 Kg activated carbon (1000 mesh) was mixed at a temperature of 200 ° C for 20 minutes, and the first base layer mixture and the second base mixture were formed;

[0064] Each will be 10kg low-density high-pressure polyethylene, 85kg high-density low-voltage polyethylene, 6kg silver silicate, 3kg ethyl vanilla, 3kg china, 6kg edible gelatin, 0.1kg water talc, 0.3kg activated carbon (1250) 15 min at a temperature of 240 ° C, forming a first stable solid layer mixture and a second stable layer mixture; 99 kg high-density low-voltage polyethylene, 1 kg silver silicate, 2kg edible gelatin, 0.3kg water talc, 0.1 Kg activated carbon (1...

Embodiment 3

[0067] Antibacterial preservation film is produced in accordance with the preparation process of the present application:

[0068] Each will 6kg low-density high pressure polyethylene, 90kg high-density low-voltage polyethylene, 3kg silver silicate, 2.5 kg of hydroxyzopylphenyl ester, 2 kg china, 0.3 kg of lactic acid, 2 kg, 7kg edible gelatin, 0.4kg water talc, 0.2 kg of activated carbon (1250) was mixed at a temperature of 240 ° C for 15 min, and the first base mixture and the second base mixture were formed;

[0069] Each will be 8kg low-density high pressure polyethylene, 92kg high-density low-voltage polyethylene, 3kg silver silicate, 1.5kg ethyl vanilla, 2kg chitin, 4kg edible gelatin, 0.2kg water talc, 0.2kg activated carbon (1000 mesh) In the temperature of 200 ° C for 20 minutes, the first stable solid layer mixture and the second stable layer mixture were formed; 96 kg high density low-voltage polyethylene, 5 kg silver silicate, 3kg edible gelatin, 0.2kg water talc, 0.25...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com