Antibacterial ceramic tile and preparation method thereof

A technology for ceramic tiles and antibacterial surfaces, applied in the field of ceramic tiles, can solve the problems that the strength, wear resistance and thermal shock resistance of ceramic tiles cannot be taken into account, and the performance of ceramic tiles is deteriorated, so as to achieve good quality, improve antibacterial durability, The effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

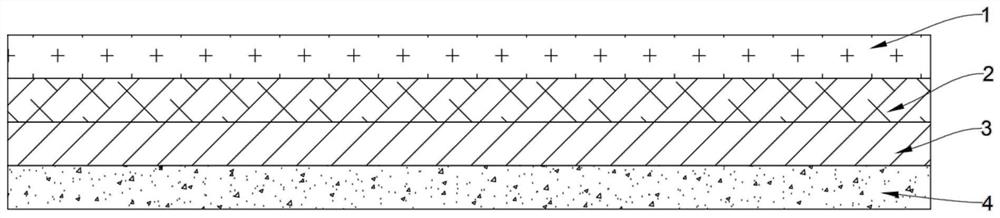

[0046] The present application also provides the preparation method of the antibacterial ceramic tile as described in any one of the above, comprising the steps of:

[0047] S1. Prepare the ceramic tile body, and pour a layer of infrared antibacterial glaze on the surface of the ceramic tile body;

[0048] S2. Form a floral glaze color glaze layer 2 on the brick surface drenched with infrared antibacterial glaze by inkjet printing and screen printing;

[0049] S3. Print a layer of transparent protective glaze on the colored glaze layer 2;

[0050] S4. Putting it into a kiln for firing to obtain a semi-finished adobe;

[0051] S5. The semi-finished adobe is polished, edged and super-clean to obtain the antibacterial ceramic tile.

[0052] The preparation of the antibacterial ceramic brick by the above steps is simple and fast, and the process is highly controllable. Prepare the ceramic body first; then add antibacterial powder, sodium carboxymethyl cellulose, sodium tripolyp...

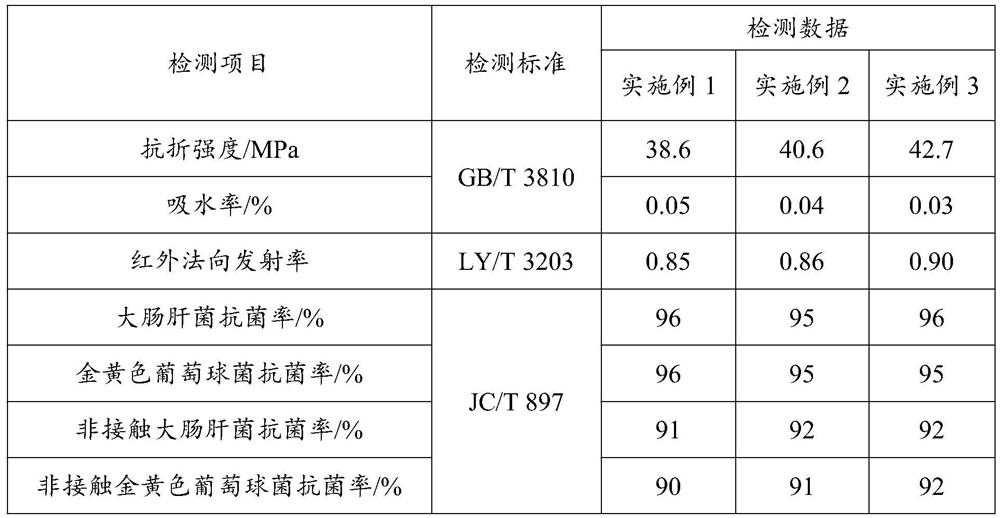

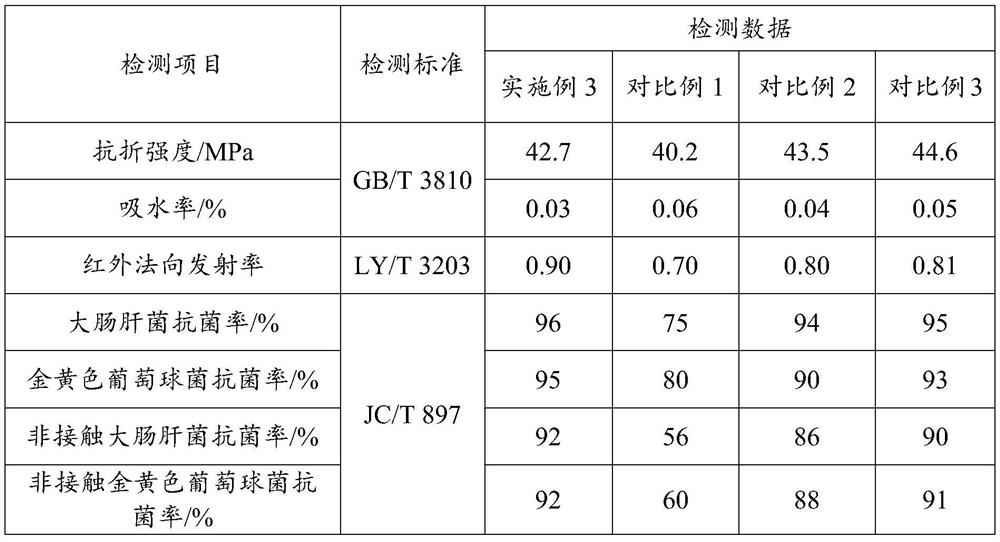

Embodiment 1

[0057] A preparation method for antibacterial ceramic tiles, comprising the steps of:

[0058] S1. Prepare the ceramic tile body, and pour a layer of infrared antibacterial glaze on the surface of the ceramic tile body;

[0059] Among them, 1.6% of infrared antibacterial material, 0.3% of sodium carboxymethylcellulose and 0.25% of sodium tripolyphosphate were added to 50.85% of the basic surface glaze and mixed evenly by weight percentage, and 47% of water ball milled for 8 hours to obtain the Infrared antibacterial glaze;

[0060] The infrared antibacterial material is mixed with 99% potassium sodium stone powder and 1% rare earth oxide, and then sintered at 1170°C for 65 minutes and then pulverized. The rare earth oxide includes La 2 o 3 and Pr 8 o 11 ;

[0061] S2. Form a floral glaze color glaze layer 2 on the brick surface drenched with infrared antibacterial glaze by inkjet printing and screen printing;

[0062] S3. Print a layer of transparent protective glaze on ...

Embodiment 2

[0067] A preparation method for antibacterial ceramic tiles, comprising the steps of:

[0068] S1. Prepare the ceramic tile body, and pour a layer of infrared antibacterial glaze on the surface of the ceramic tile body;

[0069] Among them, 1.7% of infrared antibacterial material, 0.4% of sodium carboxymethyl cellulose and 0.4% of sodium metasilicate were added to 49.5% of the basic surface glaze and mixed evenly by weight percentage, and 48% of water ball milled for 8.5h to obtain The infrared antibacterial glaze;

[0070] The infrared antibacterial material is made by mixing 97.5% potassium sodium stone powder and 2.5% rare earth oxide, sintering at 1195° C. for 75 minutes, and pulverizing. The rare earth oxide includes Gd 2 o 3 and Dy 2 o 3 ;

[0071] S2. Form a floral glaze color glaze layer 2 on the brick surface drenched with infrared antibacterial glaze by inkjet printing and screen printing;

[0072] S3. Print a layer of transparent protective glaze on the colore...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com