A kind of dielectric ceramic, multilayer ceramic capacitor

A dielectric and ceramic technology, applied in the field of multilayer ceramic capacitors, can solve the problems of inability to improve product thermal shock resistance, undefined secondary phase size, poor thermal shock resistance, etc., to improve thermal shock resistance and improve bonding Force, the effect of improving thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the multilayer ceramic capacitor of embodiment 1-9 and comparative example 1-8 comprises the following steps:

[0035] (1) Prepare Ba compound and Ti compound, prepare Ca compound, Sr compound, Zr compound and Hf compound according to actual needs, prepare barium titanate compound powder with an average particle size of 0.1-0.3 μm as the main component, barium titanate The compound powder can be prepared by solid phase method, co-precipitation method, hydrothermal method, oxalate method and other methods;

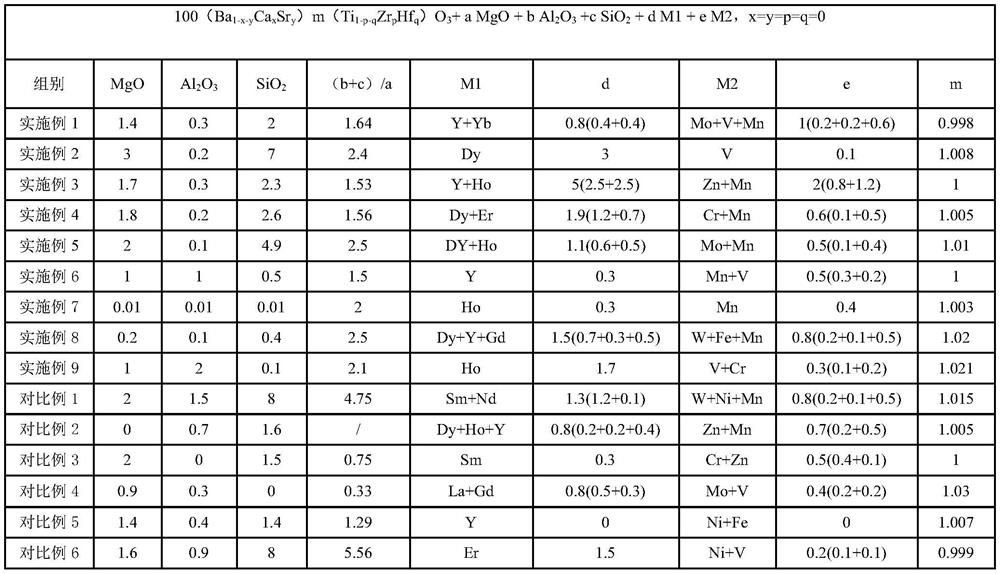

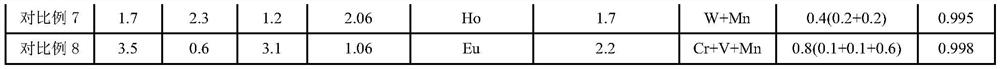

[0036] (2) According to the composition of Table 1, prepare minor components such as rare earth compounds, transition metal compounds, and Si compounds, and weigh according to a predetermined ratio; then these weighing objects are mixed with BaTiO 3 The powder, pulverization medium and pure water are put into the ball mill together, fully mixed and pulverized in a wet way, mixed, and dried to obtain ceramic raw material powder;

[0037] (3)...

Embodiment 4

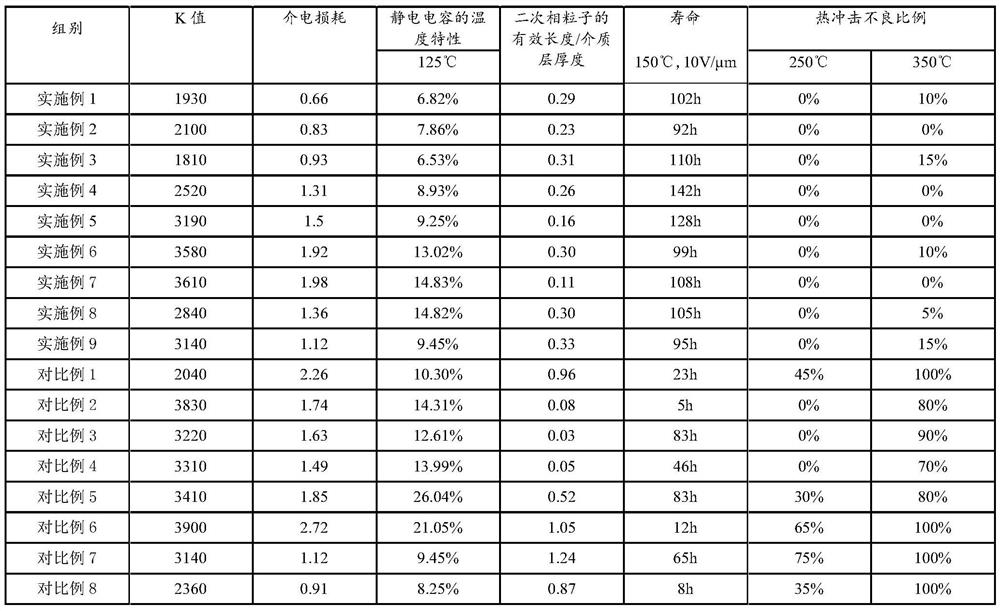

[0060] Example 4 has relatively moderate (b+c) / a value, m value, and its secondary phase length also conforms to 1 / 10<the effective length of the long rod-shaped secondary phase particles / the thickness of the dielectric layer of the multilayer ceramic capacitor< The requirement of 1 / 3 improves the thermal shock resistance of the product while ensuring the product life characteristics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com