Preparation process of high-purity nicotine

A preparation process and technology of nicotine, which is applied in the field of industrial waste resource treatment, can solve the problems of high energy consumption, large solvent loss, and long time, and achieve the effects of improving economic benefits, reducing dosage, and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

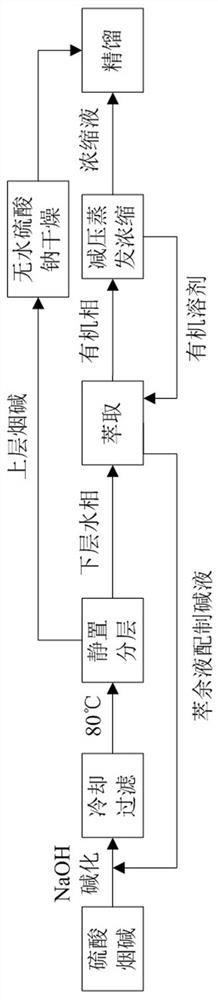

Image

Examples

Embodiment 1

[0019] Add 500L 40% nicotine sulfate to the 1000L jacketed reactor, then add 175L 32% NaOH, stir at room temperature for 15 minutes, then circulate water to cool the system until the system is maintained at 9°C, and let it stand for 2.5 hours. During this period, a little stirring can be used to promote the precipitation of crystals. After the precipitation is complete, centrifuge and filter, and the crude product sodium sulfate decahydrate obtained by filtration can be used for the preparation of anhydrous sodium sulfate. The filtrate was heated to 80°C with slow stirring in the heating kettle, then the temperature was kept and the stirring was stopped, and the mixture was left to stand for 20 minutes to wait for obvious separation. The upper organic layer (about 280 L) was separated and dried over 20 kg of anhydrous sodium sulfate. The lower aqueous phase (about 390L) is extracted with 1200L No. 6 solvent oil (centrifugal extraction or disc extraction), the extract is conce...

Embodiment 2

[0021] Add 400L 45% nicotine sulfate to a 1000L jacketed reactor, then add 140L 35% NaOH, stir at room temperature for 15 minutes, then circulate water to cool the system until the system is maintained at 7°C, and let stand for 2.5 hours; centrifuge and filter the obtained crude product after the precipitation is complete Sodium sulfate decahydrate was used for the preparation of anhydrous sodium sulfate; the filtrate was slowly stirred and heated to 82°C in a heating kettle, then kept at the temperature and stopped stirring, and stood for 20 minutes to wait for obvious separation. About 220 L of the upper organic layer was separated and dried with 20 kg of anhydrous sodium sulfate. The lower aqueous phase (about 320L) is extracted with 1000L No. 6 solvent oil (centrifugal extraction or disc extraction), the extract is concentrated under reduced pressure, the solvent is recovered, and the concentrated crude nicotine is combined with the above crude nicotine for rectification ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com