A kind of self-anastomosis artificial vascular stent and preparation method thereof

A technology of artificial blood vessels and composite stents, applied in the field of biomedical tissue engineering, can solve the problems of long operation time, high quality and technical requirements for surgeons, and high requirements for the operation environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

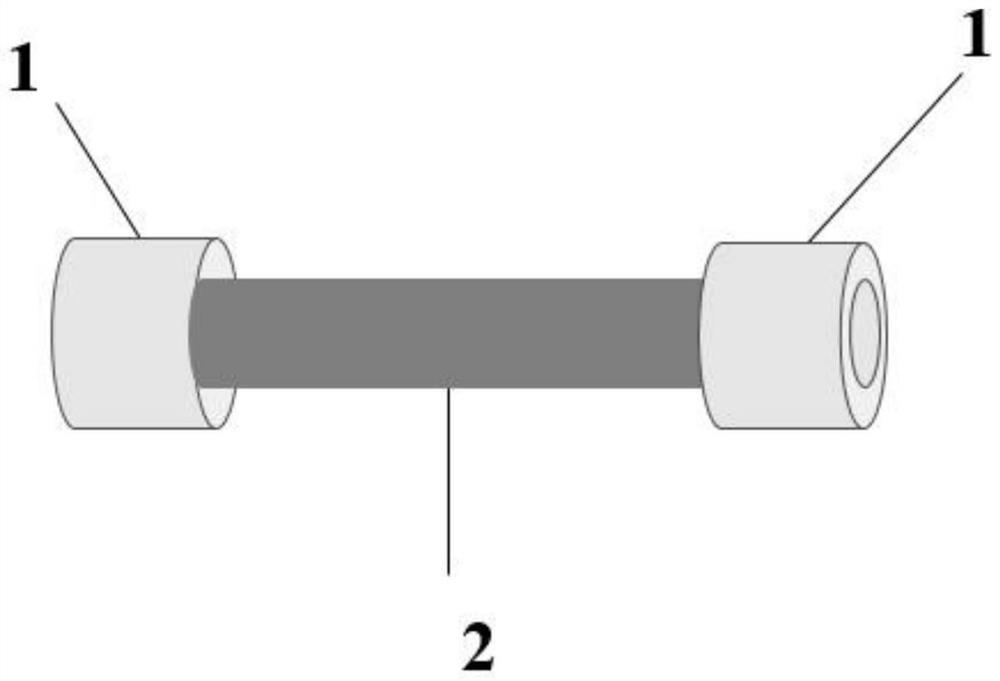

[0028] The invention provides a method for preparing a self-anastomotic artificial vascular stent, comprising the following steps:

[0029] (1) Using the polymer solution as the spinning solution, the electrospun membrane is prepared by electrospinning, and then the electrospun membrane is rolled to obtain the vascular inner layer stent;

[0030] (2) Using a mixed solution of sodium alginate, gelatin and carbon nanotubes as the printing material, extruding and printing the middle layer of the blood vessel bracket on the outer surface of the vascular inner layer stent obtained in the step (1), to obtain a double-layer stent;

[0031] (3) Using shape memory material as the printing material, extrude and print an anastomotic sleeve at both ends of the double-layer stent in the step (2) to form a composite stent; the inner diameter of the anastomotic sleeve and the inner layer of the blood vessel The inner diameter of the bracket is the same;

[0032] (4) Using polycaprolactone s...

Embodiment 1

[0083] a. Preparation of endovascular stent

[0084] Configuration of polymer solution:

[0085] (1) Prepare a 5% heparin solution with 0.05mol / L, pH=6.0 2-morpholineethanesulfonic acid buffer solution;

[0086] (2) Mix 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride, N-hydroxysuccinimide and the above-mentioned heparin solution according to the ratio of 2:1.3:1 Mix and react for 30 minutes to obtain a mixed solution; then add 1 g of silk fibroin to 50 mL of the above mixed solution, and obtain a heparinized silk fibroin solution after 5 hours;

[0087] (3) Take 2g of polycaprolactone and 10mL of heparinized silk fibroin solution and dissolve them in 10mL of hexafluoroisopropanol to obtain a polymer solution;

[0088] Preparation of vascular inner layer scaffold by electrospinning:

[0089] Put the above polymer solution in a water tank at 37°C, stir at a rate of 400r / min for 0.5h, let it stand for 1h, then put it into a syringe, select a 23G nozzle, set the hig...

Embodiment 2

[0109] a. Preparation of endovascular stent

[0110] Configuration of polymer solution:

[0111]Take 2 g of polycaprolactone, dissolve it in a mixed solvent made of 7 mL of dichloromethane and 3 mL of dimethylformamide, and let it stand for 6 hours to fully dissolve the polycaprolactone to obtain a polycaprolactone solution;

[0112] Preparation of vascular inner layer stent:

[0113] Stir the obtained polycaprolactone solution for 0.5h, let it stand for 1h, defoam, put it into a syringe, select a 23G nozzle, set the high-voltage voltage parameter to 10kV, and set the distance from the nozzle to the collector to 10cm, and then use 16.6μL Electrospun at a flow rate of / min to obtain an electrospun membrane; the obtained electrospun membrane was rolled into a tubular shape with a stainless steel rod with a diameter of 4 mm, and 8 cm was selected as the inner layer of the blood vessel to obtain an inner diameter of 4 mm, a length of 8 cm, and a thickness of 4 mm. 0.2mm vascular...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com