A kind of biomass waste treatment equipment

A technology for biomass waste and processing equipment, applied in grain processing, crop processing machines, furniture waste recycling, etc., can solve the problems of single crushing structure, large dust of biomass waste, low work efficiency, etc., to improve safety performance, High quality crushing effect

Active Publication Date: 2022-06-03

江山华隆能源开发有限公司

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The current biomass equipment has the following defects: 1. The treatment equipment is only aimed at a certain type of biomass waste, and the quality of life in rural areas is now improved, and there are more kitchen waste. Requires different equipment and therefore does not fit current usage

[0005] 2. Some biomass wastes are very dusty and are easy to splash when crushed, posing risks

[0006] 3. The crushing structure is single, and the crushing is not thorough enough. At the same time, the crushed waste needs to be screened by screening equipment, and the work efficiency is slow in step by step.

[0007] 4. Because the crushing structure is generally installed inside the equipment, if the crushing structure is entangled and blocked by waste such as straw and wood, the crushing components will stop working and it will be difficult to clean, resulting in low work efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

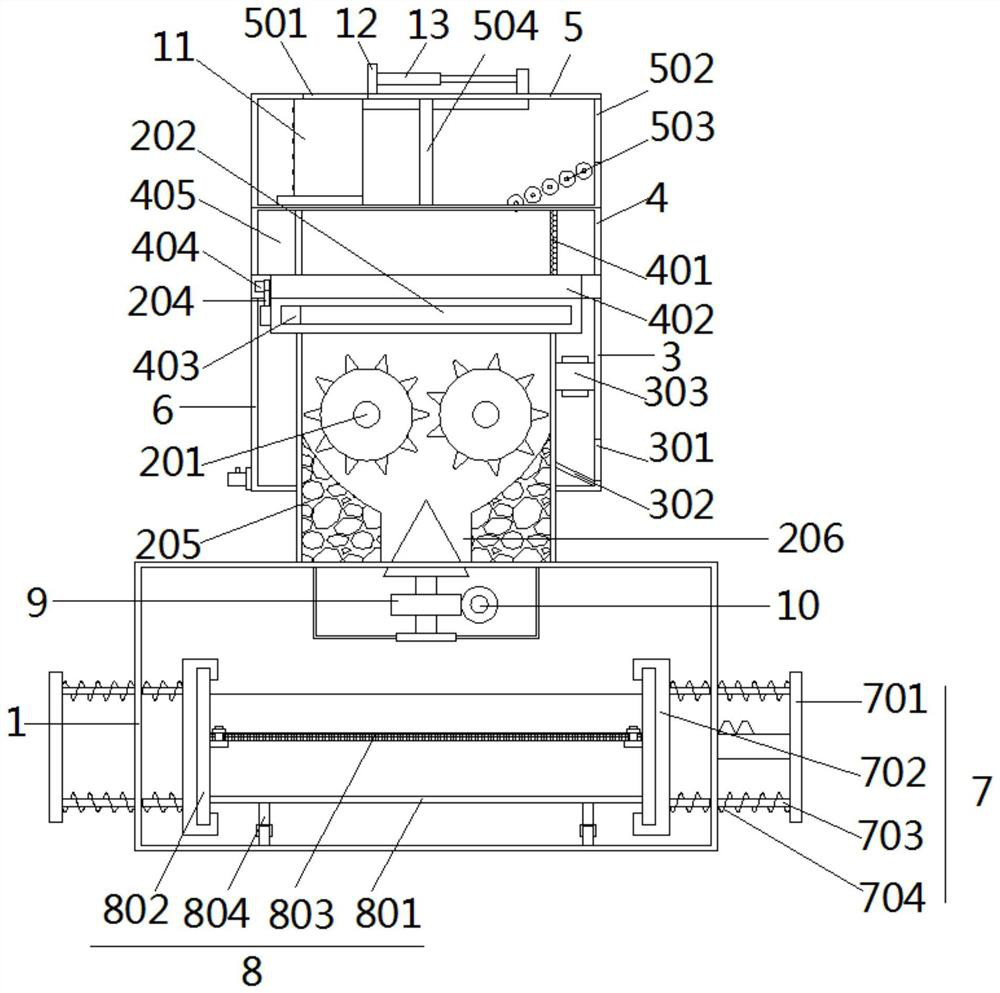

[0042] Wherein: the extrusion device 11 also includes a die plate 111, an extrusion plate 112, a push plate 113, a drive rod 114, a hollow groove

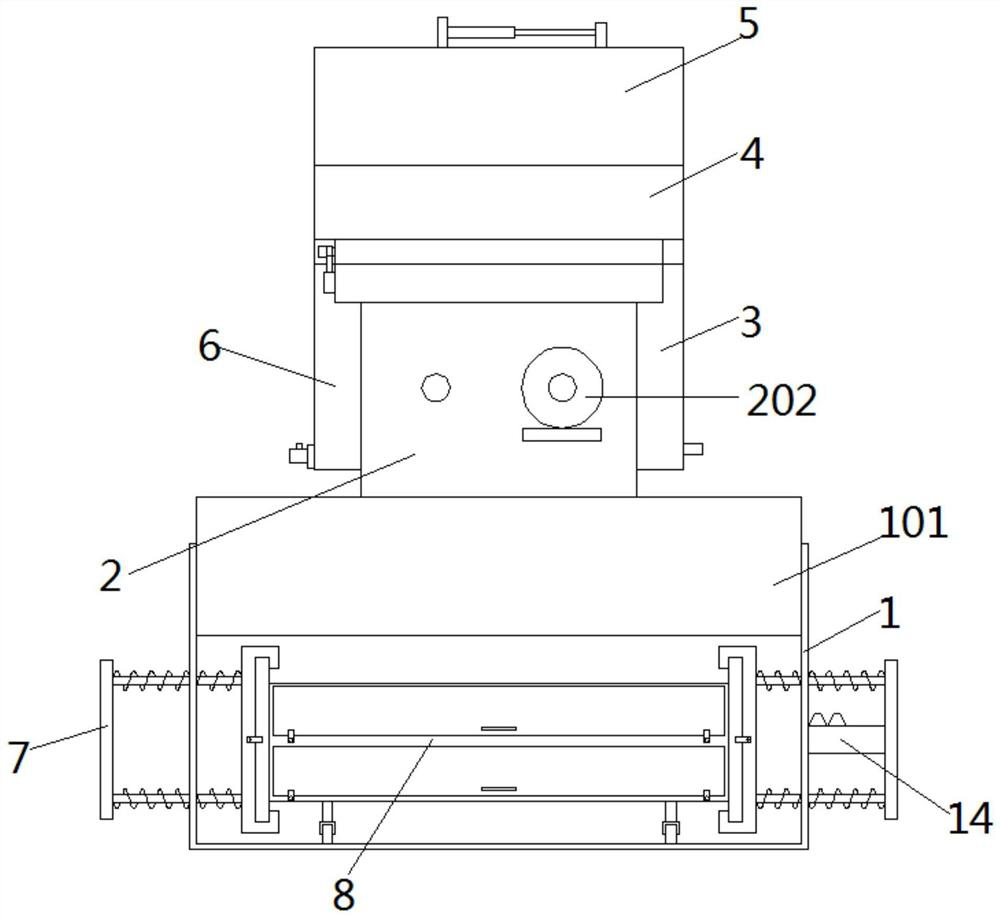

[0047] Wherein: the support swing device 7 also includes a connecting plate 701, a snap plate 702, a connecting rod 703, a No. 1 return spring

[0049] Among them: the servo motor 202, the electric push rod 13, the vacuum pump 303, and the electric valve are connected to an external power supply.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

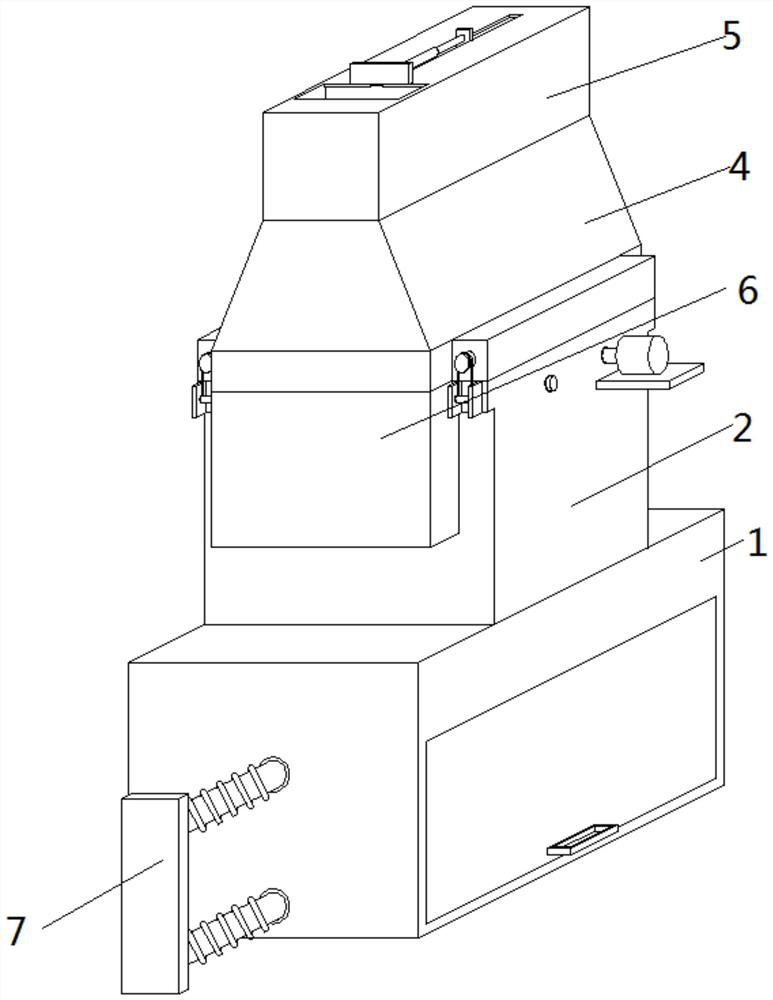

The invention provides a biomass waste treatment equipment, which includes a support box, a crushing box, a splash-proof box, a discharge box, and a water collection box. A crushing box is fixedly connected to the center of the top of the support box, and dust is fixedly connected to the front and rear sides of the crushing box. The top of the collection box, the water collection box, and the crushing box are snapped with a splash-proof box, and the top of the splash-proof box is fixedly connected with a discharge box. The center of the lower end of the front and rear sides of the support box is movably connected with a support swing device, which is located inside the support box. A collection and screening device is installed between the crushing rollers. The central axis of the crushing roller extends to the outer end of the left wall of the crushing box and is fixedly connected with gears, and the gears mesh with each other. A servo motor is installed on the upper right side of the crushing box. The output shaft of the roller is fixedly connected, and an extruding device is installed at the front end of the discharge box. The invention provides a biomass waste treatment equipment to solve the problem that the existing biomass waste treatment equipment has a single function and does not meet the actual use conditions.

Description

A kind of biomass waste treatment equipment technical field [0001] The present invention relates to the technical field of new energy, in particular to a biomass waste treatment equipment. Background technique Biomass waste is the waste produced and consumed by humans in the process of utilizing biomass, and it still belongs to the The macroscopic category of biomass, but the energy density and availability have been significantly reduced. Biomass waste includes urban biomass waste, crop waste, livestock manure, and urban biomass waste is mainly Including household kitchen waste, kitchen waste, urban manure and urban sludge; crop straw is mainly composed of corn straw, wheat straw and Rice straw is the mainstay; biomass waste, as a kind of solid waste, is an environmental pollutant that people must properly handle. Improper disposal will cause serious environmental pollution, and the current biomass waste treatment needs to be pulverized and then processed into bio...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B02C4/08B02C4/28B02C2/10B02C23/16B07B1/28B07B1/42B30B9/06A01D82/00

CPCB02C4/08B02C4/28B02C2/10B02C23/16B07B1/28B07B1/42B30B9/06A01D82/00B02C2201/06B02C2023/165Y02W30/78

Inventor 毛伟

Owner 江山华隆能源开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com