A kind of preparation method of niobium pentoxide with high bulk density

A technology of niobium pentoxide and bulk density, which is applied in chemical instruments and methods, inorganic chemistry, niobium compounds, etc., can solve the problems of not being able to prepare niobium pentoxide, achieve high bulk density, and do not pollute the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

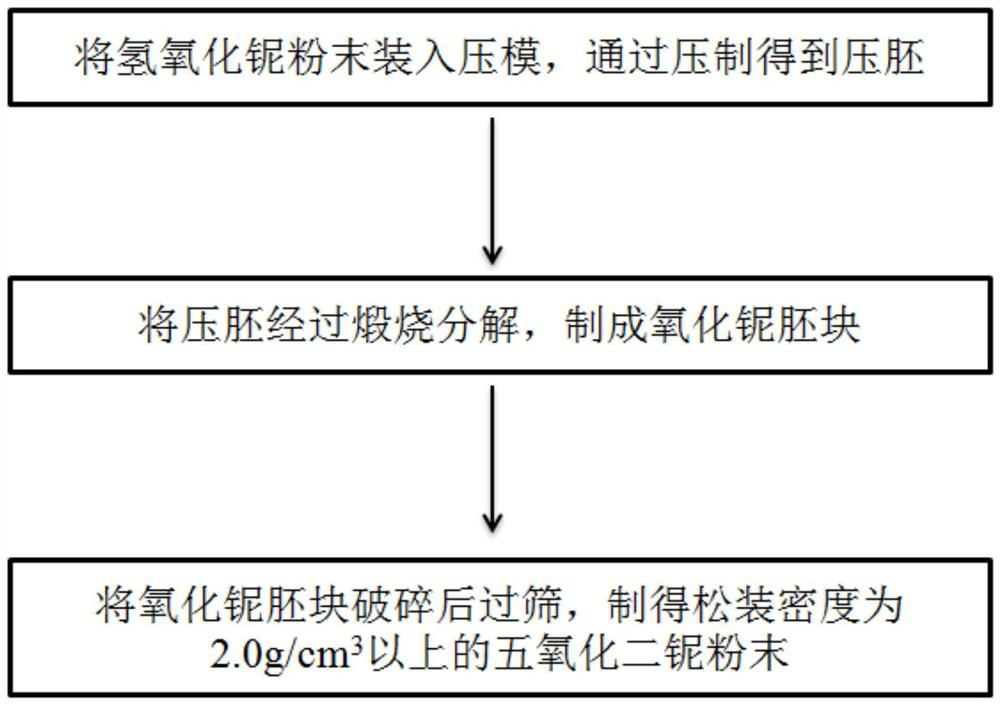

Image

Examples

Embodiment 1

[0033] The invention provides a method for preparing niobium pentoxide with high bulk density, comprising the following steps:

[0034] (1) Obtain fluoroniobic acid solution by extraction and separation method, neutralize with ammonia, wash to remove fluoride and dry at 200°C to obtain niobium hydroxide powder, put the niobium hydroxide powder into a steel mold, press pressure: 400MPa, keep Press for 10s;

[0035] (2) Put the compact into the calcination furnace at a temperature of 900°C for 8 hours, and the following reactions occur during calcination:

[0036] 2Nb(HO) 5 =Nb 2 o 5 +5H 2 O↑

[0037] Niobium hydroxide is converted into niobium pentoxide by calcination. During the process, about 25% of moisture and other volatiles escape from the pressed embryo, causing the embryo to crack and loose, which is conducive to subsequent crushing and screening;

[0038] (3) Grind and sieve the niobium oxide green block with a stainless steel mill and sieve with a 40-mesh screen...

Embodiment 2

[0040] The invention provides a method for preparing niobium pentoxide with high bulk density, comprising the following steps:

[0041] (1) Obtain oxyfluoroniobic acid solution by extraction and separation, neutralize with ammonia, wash to remove fluoride and dry at 300°C to obtain niobium hydroxide powder, and put the niobium hydroxide powder into a soft mold with an inner diameter of ¢37×600mm , cold isostatic pressing, pressure 220MPa, holding pressure 20min;

[0042] (2) Put the compact into the calciner, the temperature is 850°C, the time is 6h, the following reaction occurs during calcining:

[0043] 2Nb(HO) 5 =Nb 2 o 5 +5H 2 O↑

[0044] Niobium hydroxide is converted into niobium pentoxide by calcination. During the process, about 25% of moisture and other volatiles escape from the pressed embryo, causing the embryo to crack and loose, which is conducive to subsequent crushing and screening;

[0045] (3) Grind and sieve the niobium oxide green block with a stainle...

Embodiment 3

[0047] The invention provides a method for preparing niobium pentoxide with high bulk density, comprising the following steps:

[0048] (1) Obtain fluoroniobic acid solution by extraction and separation method, neutralize with ammonia, wash to remove fluoride and dry at 100°C to obtain niobium hydroxide powder, put the niobium hydroxide powder into a soft mold with an inner diameter of ¢37×600mm, Cold isostatic pressing, pressure 250MPa, pressure hold 30min;

[0049] (2) Put the compact into the calcination furnace at a temperature of 900°C for 8 hours, and the following reactions occur during calcination:

[0050] 2Nb(HO) 5 =Nb 2 o 5 +5H 2 O↑

[0051] Niobium hydroxide is converted into niobium pentoxide by calcination. During the process, about 25% of moisture and other volatiles escape from the pressed embryo, causing the embryo to crack and loose, which is conducive to subsequent crushing and screening;

[0052](3) Grind and sieve the niobium oxide block with a stain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com