Coated silicon-carbon negative electrode material, preparation method thereof and lithium ion battery

A negative electrode material and coating technology, which is applied in the field of battery negative electrode material preparation, can solve the problems of high cycle capacity and high cycle stability, and achieve high cycle capacity, improved cycle performance, and good cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] As described in the background art, the existing coated silicon-carbon anode materials cannot satisfy the problems of simple process, high cycle stability and high cycle capacity at the same time. In order to solve the above-mentioned technical problems, the application provides a method for preparing a coated silicon-carbon negative electrode material. The preparation method of the coated silicon-carbon negative electrode material includes: in a kneading device, silicon source, graphite and carbon source are Heating and mixing treatment to obtain a pretreated material; carbonizing the pretreated material to obtain a coated silicon-carbon negative electrode material.

[0020] In the above preparation method, before the carbonization process, a kneading device is used to heat and mix the silicon source, graphite and carbon source to form a pretreated material. Compared with conventional mixing methods, heating while mixing in a kneading device can greatly improve the deg...

Embodiment 1

[0034] A method for preparing a coated silicon-carbon negative electrode material comprises:

[0035] In the kneading pot, the silicon source (silicon powder, 60nm), artificial graphite, and sucrose are heated and mixed in a weight ratio of 1:8.5:16 to obtain the pretreated material. The heating temperature is 120°C, and the stirring blade of the kneading pot The rotation speed is 20r / min, and the stirring time is 3h.

[0036]Transfer the well-stirred silicon powder, artificial graphite, and carbon source into a quartz pot while hot, put the quartz pot into a high-temperature tube furnace, and carry out carbonization treatment according to the following roasting curve: heat up at a rate of 2°C / min to 860 After keeping warm for 3 hours at ℃, let it cool down to room temperature naturally. During the whole process, it is protected by argon gas at 50ml / min.

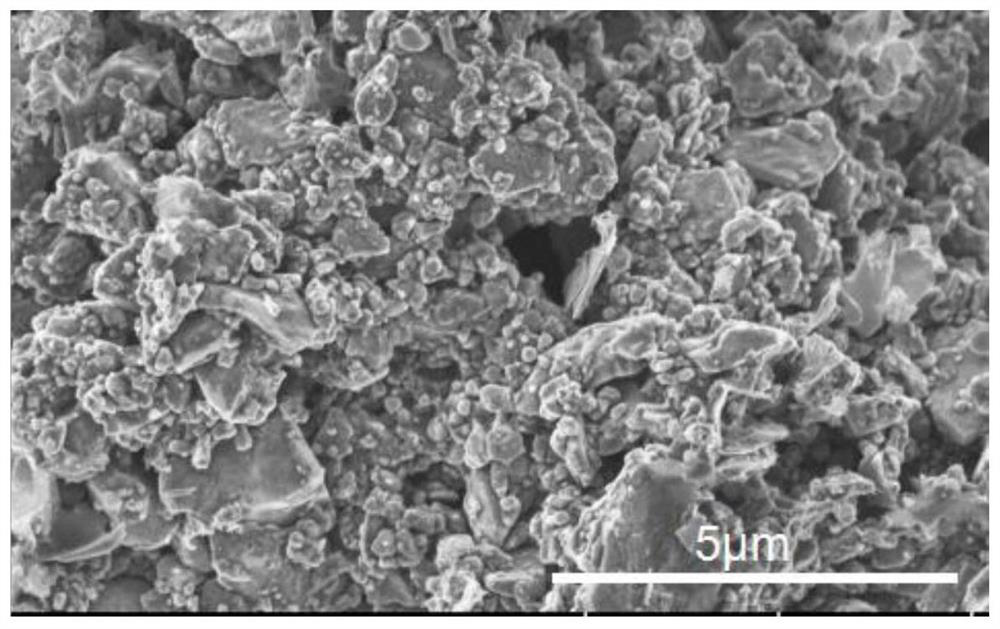

[0037] Put the carbonized product in the above-mentioned high-temperature tube furnace in a zirconium spherical tank and ...

Embodiment 2

[0040] The difference with Example 1 is: in the kneading pot, the silicon source (silicon powder, 60nm), artificial graphite, and sucrose are heated and mixed in a weight ratio of 1:2:20 to obtain a pretreated material, wherein the heating temperature is 120°C, the rotating speed of the stirring knife in the kneading pot is 10r / min, and the stirring time is 5h.

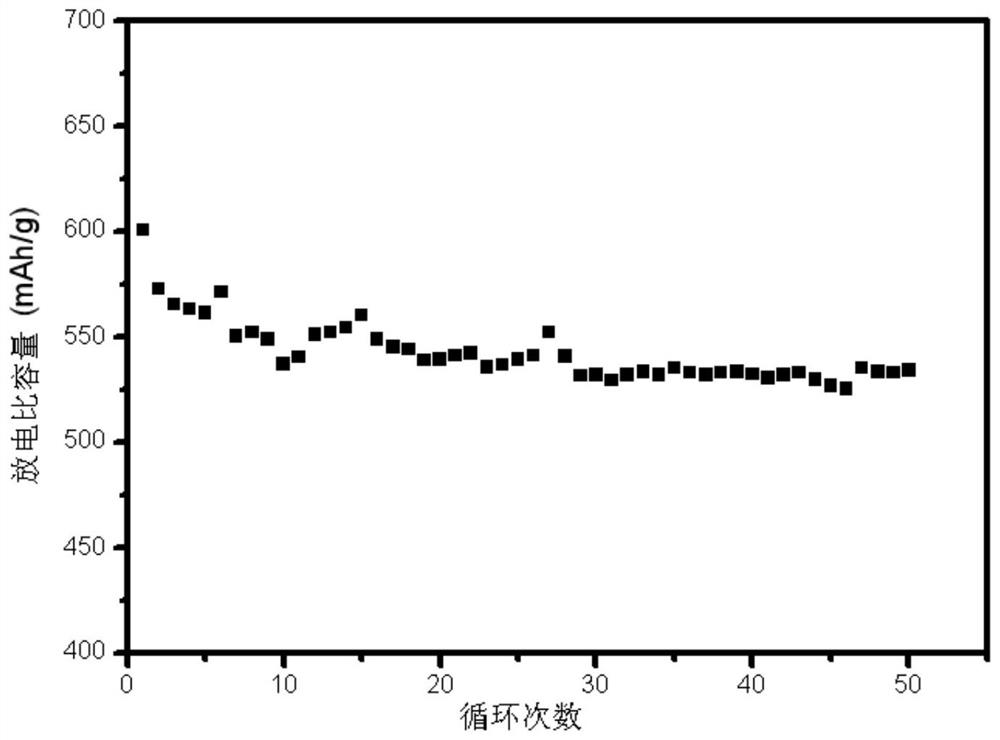

[0041] The initial capacity is 1405mAh / g, the initial efficiency is 85%, and the capacity retention rate of 50 cycles is 82%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com