Gel electrolyte diaphragm, preparation method thereof and lithium ion battery

A technology of gel electrolyte and diaphragm, which is applied in the direction of secondary batteries, battery components, circuits, etc., can solve the problems affecting the formation of SEI film, achieve the elimination of doping or coating modification, save production costs, and improve the electrical conductivity. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] Another embodiment of the present invention provides a preparation method of a gel electrolyte separator, comprising the following steps:

[0054] S1, mix the high molecular polymer material with an organic solvent, stir and heat in a water bath to obtain a mixture;

[0055] S2, adding bistrifluoromethanesulfonimide lithium and guanidine salt ionic liquid to the mixture, stirring to obtain a milky white gel polymer;

[0056] S3, cast the gel polymer on the carrier, and then use a scraper to scrape the membrane;

[0057] S4, drying the carrier in a vacuum drying oven to obtain a gel electrolyte membrane.

[0058] In one embodiment, the specific operation of step S1 is to add high molecular polymer material and pore-forming agent to the weighing bottle for mixing, for example, adding polyvinylidene fluoride (PVDF) and polyvinylpyrrolidone (PVP) for mixing. , then add N,N-dimethylformamide (DMF) and dichloromethane (DCM) dropwise to the weighing bottle with a dropper, pl...

Embodiment 1

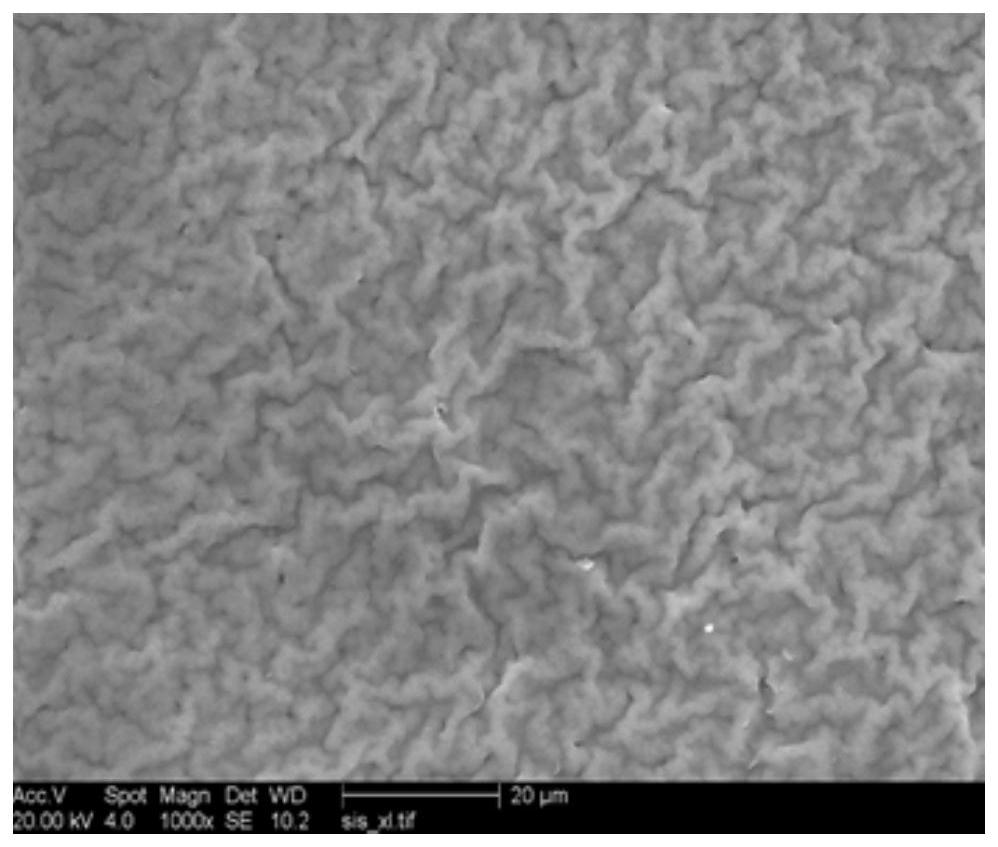

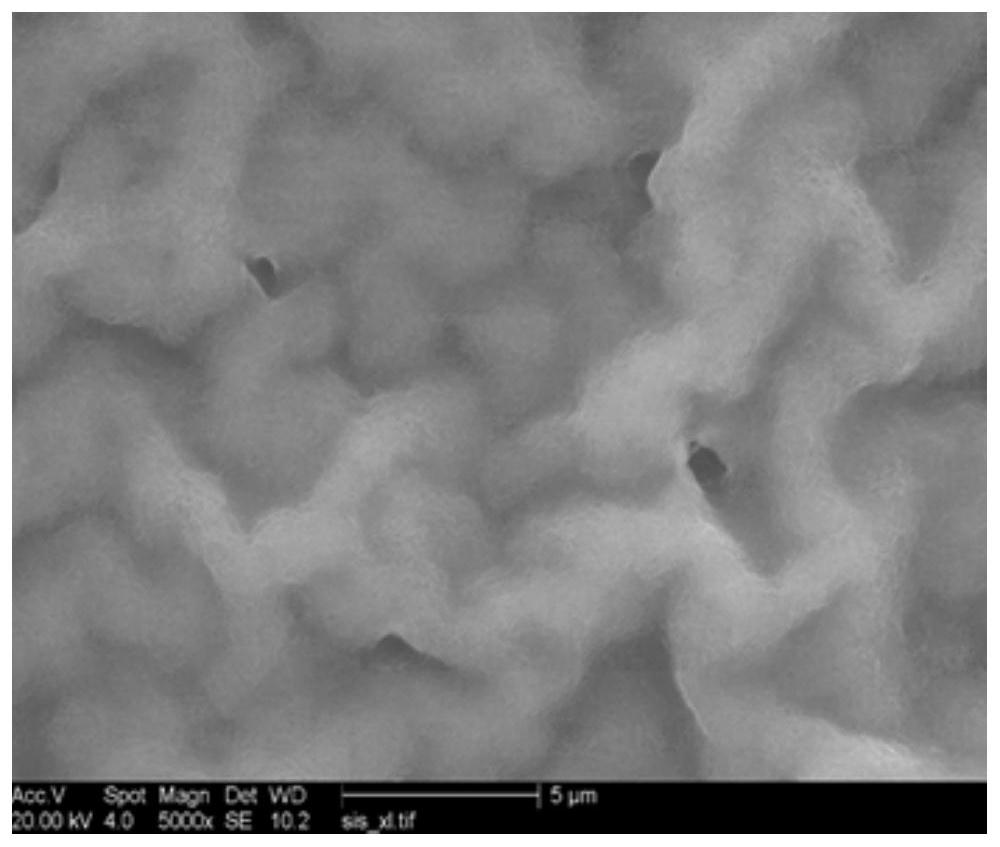

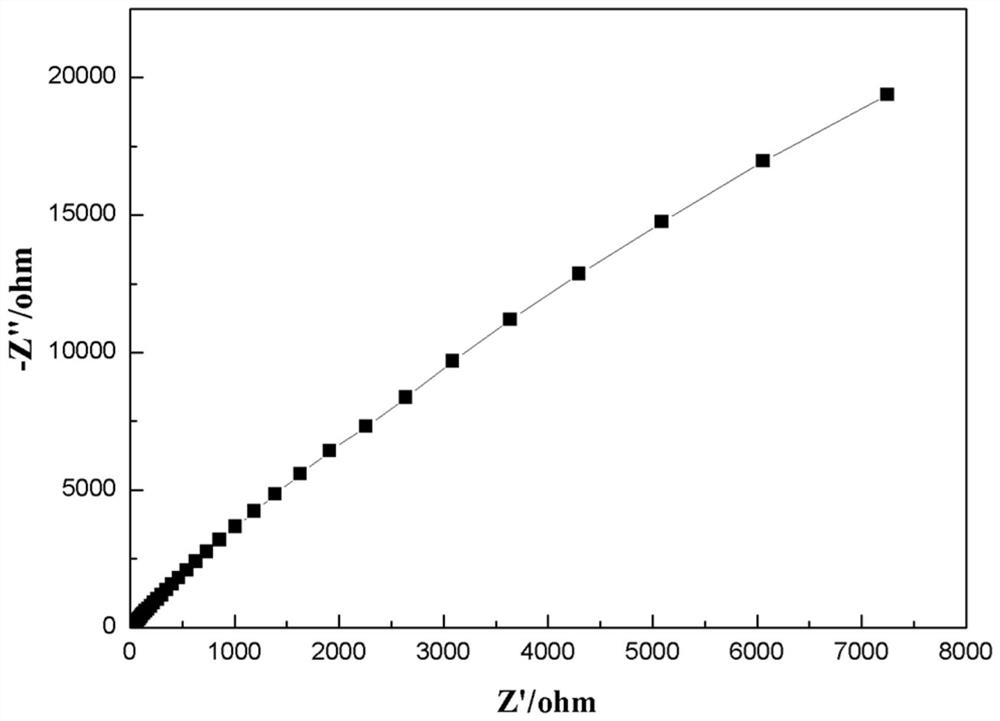

[0070] This example is used to illustrate the gel electrolyte separator disclosed in the present invention and the preparation method thereof.

[0071] In terms of mass percentage, the gel electrolyte separator includes the following weight components: 71.43 parts of polyvinylidene fluoride, 2.14 parts of polyvinylpyrrolidone, 21.43 parts of lithium bistrifluoromethanesulfonimide and 5.0 parts of guanidine salt ions liquid. In the guanidine salt ionic liquid, X is Cl, R 1 , R 2 , R 3 , R 4 Both are n-hexyl, R 5 , R 6 Not limited.

[0072] The preparation method of the gel electrolyte separator comprises the following steps:

[0073] (1) Add 10.0g PVDF (polyvinylidene fluoride) and 0.30g PVP (polyvinylpyrrolidone) to the weighing bottle, then add 20ml DMF and 5ml DCM dropwise to the weighing bottle as a solvent with a dropper, and weigh The bottle was stirred on a magnetic stirrer, heated in a water bath at 35°C and stirred for 6h;

[0074] (2) In step (1), the weighin...

Embodiment 2

[0098] In terms of mass percentage, the gel electrolyte separator includes the following weight components: 68.44 parts of polyvinylidene fluoride, 1.03 parts of polyvinylpyrrolidone, 20.53 parts of lithium bistrifluoromethanesulfonimide and 10 parts of guanidine salt ions liquid. In the guanidine salt ionic liquid, X is BF 6 , R 1 , R 2 , R 3 , R 4 Both are n-octyl, R 5 , R 6 Not limited.

[0099] The preparation method of the gel electrolyte separator comprises the following steps:

[0100] (1) Add 10.0g PVDF (polyvinylidene fluoride) and 0.15g PVP (polyvinylpyrrolidone) to the weighing bottle, then drop 17ml DMF and 8ml DCM into the weighing bottle as a solvent with a dropper, and weigh The bottle was stirred on a magnetic stirrer, heated in a water bath at 40°C and stirred for 5h;

[0101] (2) The weighing bottle in step (1) was removed from the stirrer, and 3g of lithium bistrifluoromethanesulfonimide and 1.46g of guanidine salt ionic liquid were added, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com