Method for preparing functional postoperative anti-adhesion material through 3D printing

A 3D printing and shaping technology, used in surgery, pharmaceutical formulations, medical science, etc., can solve problems such as application limitations, adhesion failure of anti-adhesion materials, etc., to achieve safe handling and use, keep the wound moist, and meet individual requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0033] Specific Embodiment 1: In this embodiment, the method for preparing functional postoperative anti-adhesion materials by 3D printing is carried out according to the following steps:

[0034] One, the preparation of N, O-carboxymethyl chitosan:

[0035] Add chitosan powder into isopropanol, stir magnetically for 8-24h at a temperature of 25-80°C, then add NaOH solution to the mixed solution every 5min, add NaOH solution 5-12 times in total, and then Add chloroacetic acid dropwise to the mixed solution 5 times within 20 minutes, adjust the temperature of the reaction solution to 40-80°C for 2-8 hours, stop the reaction with an excess of 75-80v / v% ethanol aqueous solution, and then use 75- Wash the precipitate with 80v / v% ethanol aqueous solution for 2-4 times, then continue to wash with absolute ethanol for 3-5 times, and finally dry the precipitate in a vacuum oven to obtain a water-soluble N,O-carboxymethyl shell Glycans (N,O-CS);

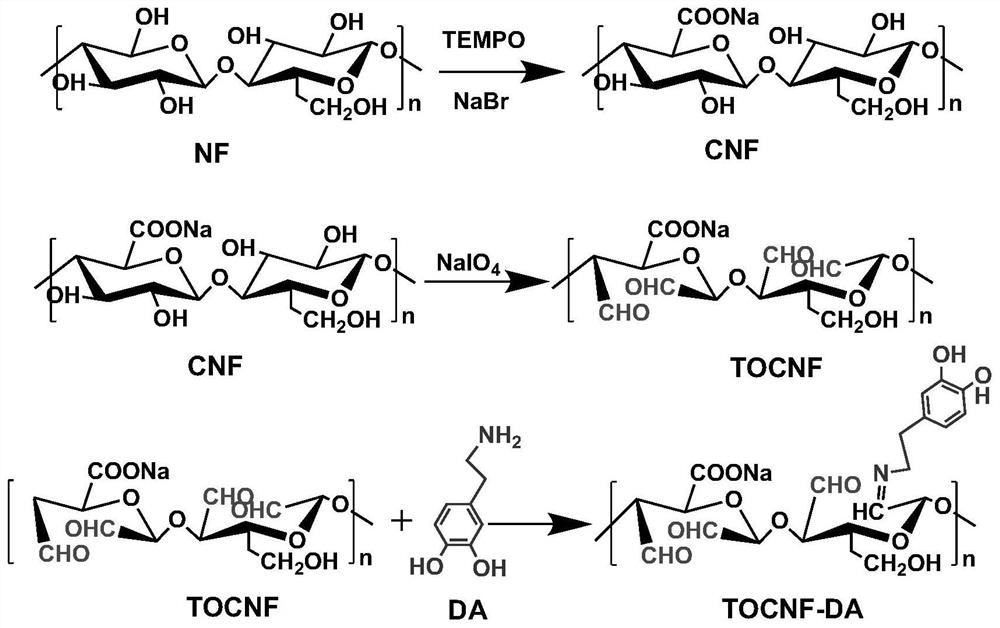

[0036] 2. Preparation of aldehydated...

specific Embodiment approach 2

[0046] Embodiment 2: This embodiment differs from Embodiment 1 in that: the drying time in step 1 is 18-24 hours, and the drying temperature is 40-60°C.

specific Embodiment approach 3

[0047] Specific embodiment three: this embodiment is different from body implementation one or two: the ratio of the quality of chitosan described in step one and the volume of isopropanol is 1g: (5-12) mL; Said chitosan The ratio of the mass of NaOH solution to the volume of all the NaOH solutions added is 1g:2.5mL; the concentration of NaOH solution is 10mol / L; the mass ratio of chitosan to chloroacetic acid is 1:(2-6). The chitosan is milky white powder, the degree of deacetylation is 80%, and the grade is medical grade.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com