Ultrasonic reflux extraction and concentration equipment

A reflux extraction and ultrasonic technology, applied in the field of ultrasonic reflux extraction and concentration equipment, can solve the problems of poor heat preservation effect, increased power consumption, low concentration efficiency, etc., and achieve the effects of avoiding solvent waste, reducing labor intensity and high degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

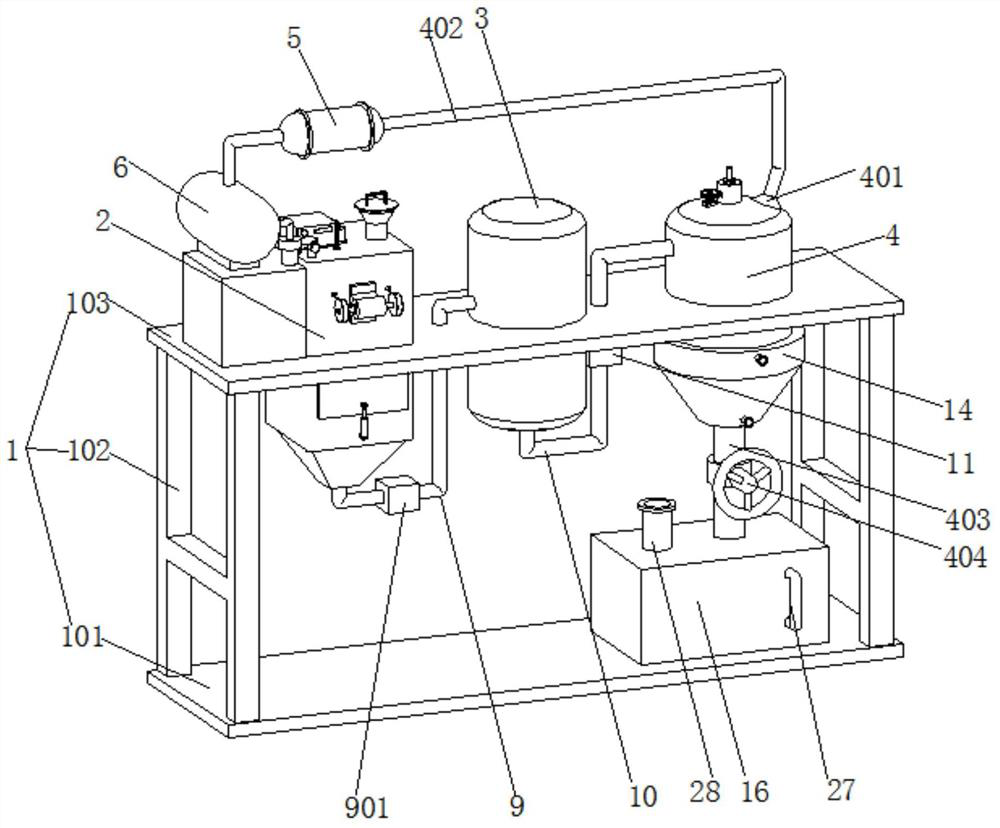

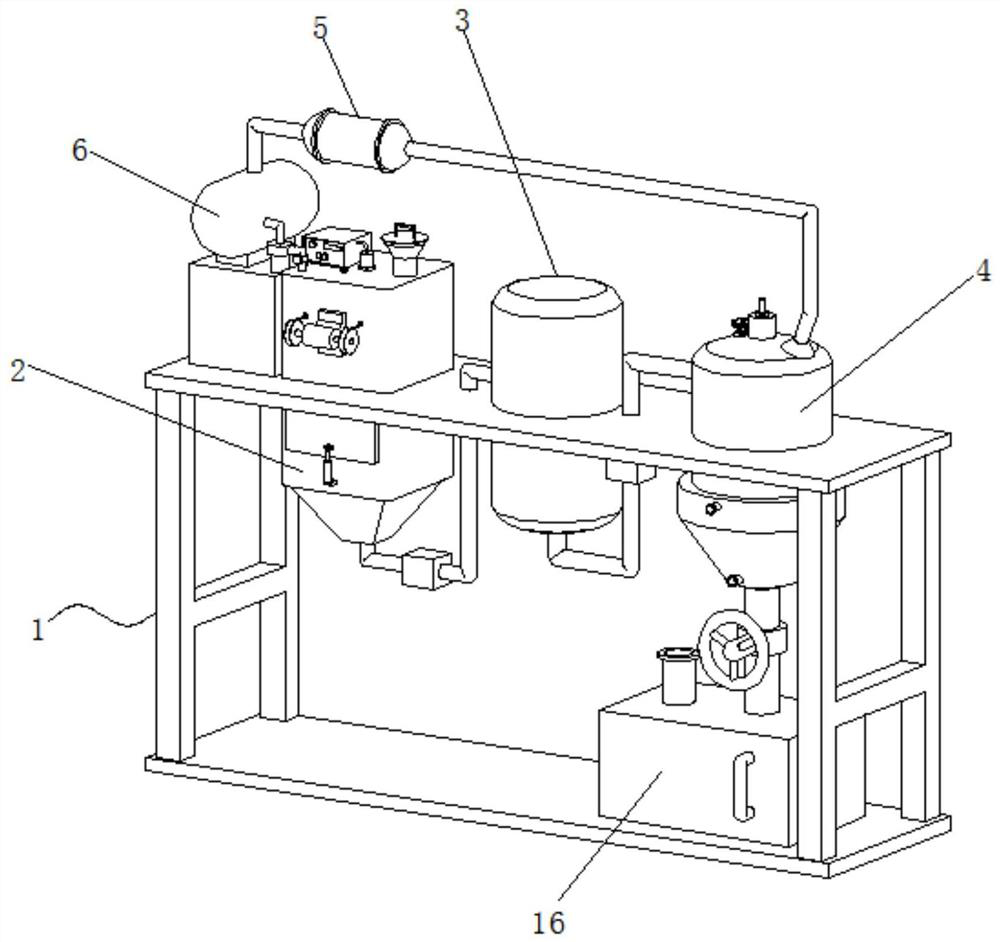

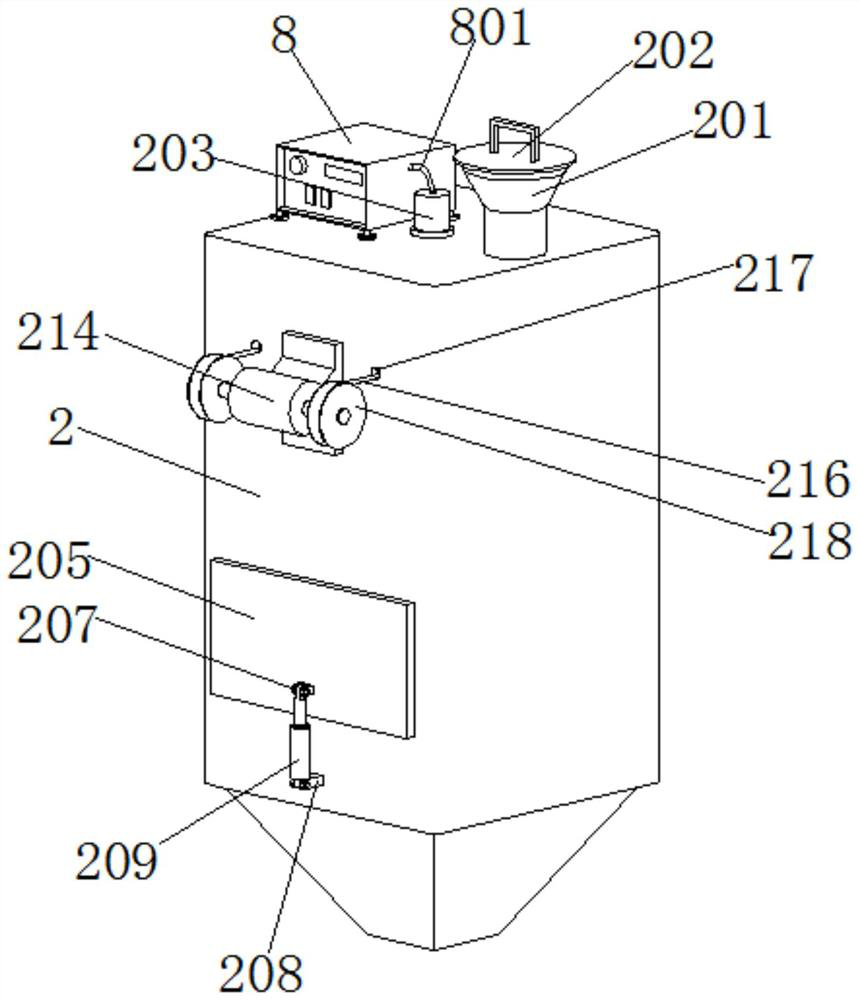

[0038] This embodiment 1 introduces a kind of ultrasonic reflux extraction and concentration equipment, refer to the attached figure 1 And attached figure 2 ,, Its main equipment includes a frame 1, and on the frame 1, an ultrasonic extraction tank 2, an intermediate filter tank 3 for extraction liquid, an evaporation concentration tank 4, a condenser 5 and a solvent storage tank 6 are fixedly arranged on the frame 1 from left to right. Specifically, its frame 1 includes a base plate 101, four vertical legs 102 and a top plate 103, and the upper and lower ends of the four vertical legs 102 are respectively fixedly connected to the four corners of the top plate 103 and the bottom plate 101, and then the ultrasonic extraction The tank 2 , the intermediate filter tank 3 of the extract, the evaporation and concentration tank 4 , the condenser 5 and the solvent storage tank 6 are fixedly arranged on the top plate 103 in sequence from left to right.

[0039] Reference attached i...

Embodiment 2

[0047] This embodiment 2 introduces a kind of ultrasonic reflux extraction and concentration equipment improved on the basis of embodiment 1, refer to the attached figure 1 And attached figure 2 ,, Its main equipment includes a frame 1, and on the frame 1, an ultrasonic extraction tank 2, an intermediate filter tank 3 for extraction liquid, an evaporation concentration tank 4, a condenser 5 and a solvent storage tank 6 are fixedly arranged on the frame 1 from left to right. Specifically, its frame 1 includes a base plate 101, four vertical legs 102 and a top plate 103, and the upper and lower ends of the four vertical legs 102 are respectively fixedly connected to the four corners of the top plate 103 and the bottom plate 101, and then the ultrasonic extraction The tank 2 , the intermediate filter tank 3 of the extract, the evaporation and concentration tank 4 , the condenser 5 and the solvent storage tank 6 are fixedly arranged on the top plate 103 in sequence from left to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com