Preparation method of catalyst for preparing low-carbon olefin from synthesis gas

A low-carbon olefin and catalyst technology, applied in the field of olefin preparation, can solve the problems of easy overheating, difficulty in removing heat from the reaction, and easy deactivation of the catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

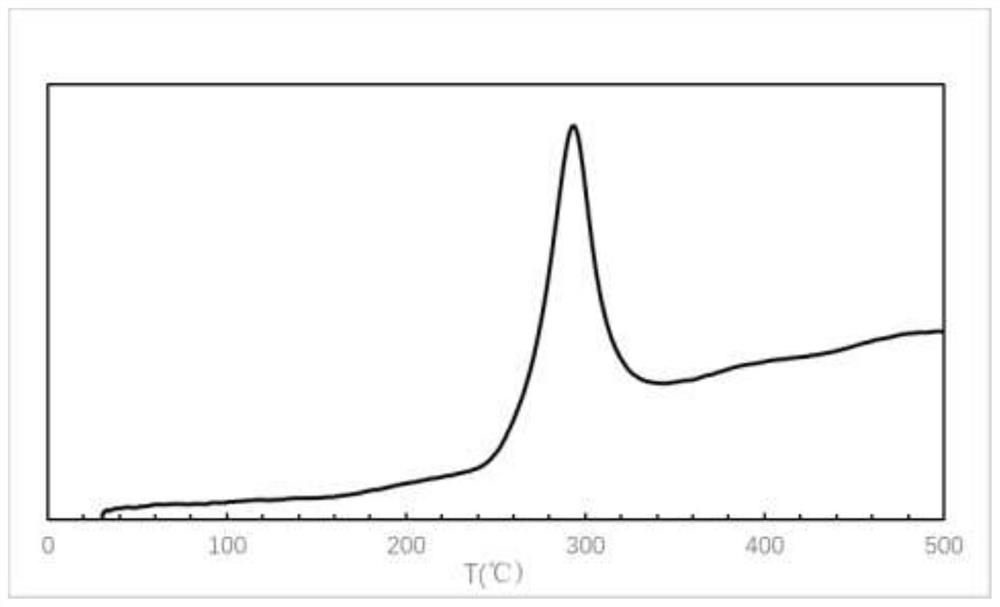

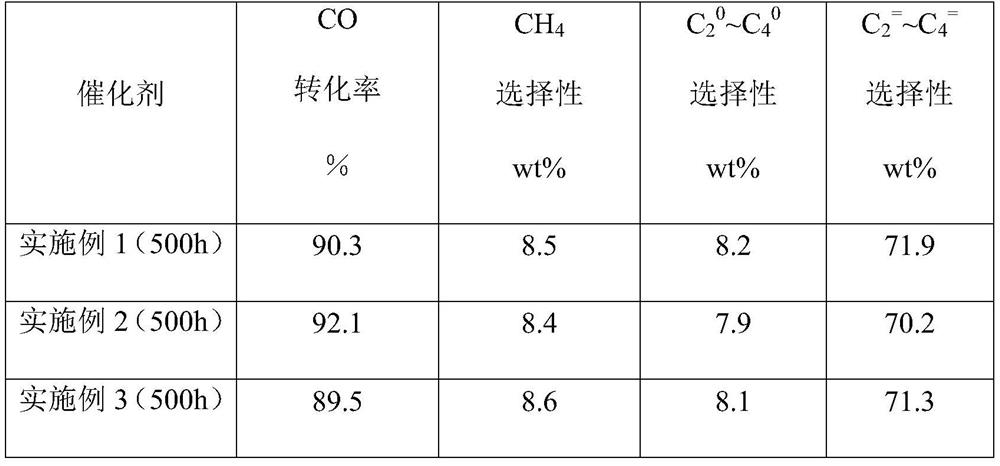

Embodiment 1

[0034] 1) Catalyst preparation:

[0035] Take 1mol of Fe(NO 3 ) 3 9H 2 Dissolve O in water to make a 0.5mol / L Fe element solution; take 0.1mol of Cu(NO 3 ) 2 ·6H 2 O is dissolved in water to make a 0.5mol / L Cu element solution; 0.05mol RbNO 3 Dissolve in water to form a 30wt% Rb element solution; mix the above three solutions together to form solution I; take 3mol of nano-TiO 2Add to the above solution I and stir to obtain slurry II; heat slurry II to 80°C in a water bath at 80°C, adjust the pH value of the slurry to 5 with ammonia water with a concentration of 25wt%, to obtain slurry III, adjust the slurry The solid content of the material reaches 35%, and the slurry IV is obtained; the slurry IV is spray-dried and molded, the inlet temperature of the sprayer is 320°C, and the outlet temperature is 190°C; then roasted, the roasting temperature is 600°C, and the roasting time is 3h, and the catalyst particles are obtained. , and its composition is: Fe 100 Cu 10 Rb 5 ...

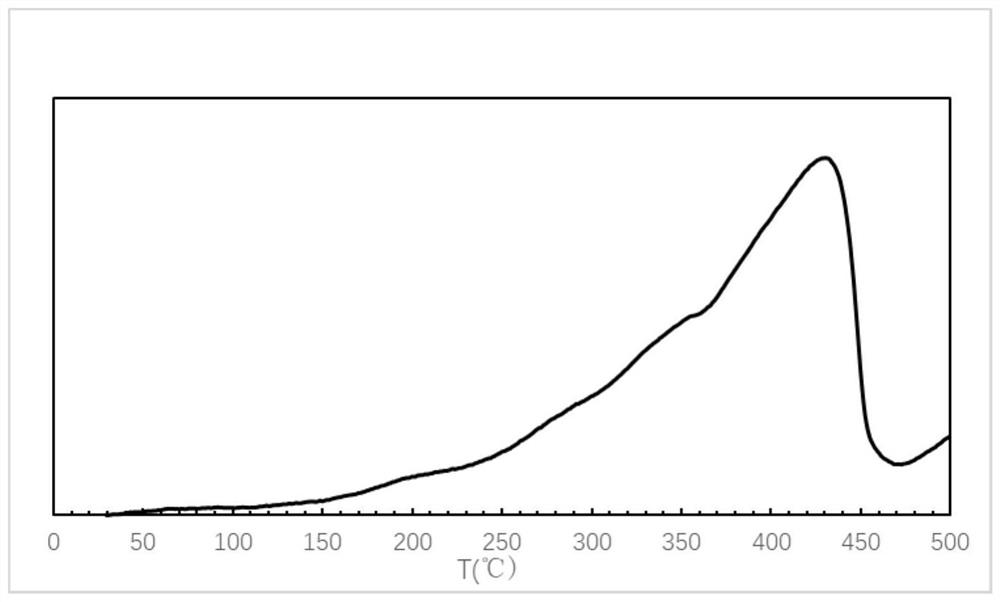

Embodiment 2

[0052] 1) Catalyst preparation:

[0053] Take 1mol of Fe(NO 3 ) 3 9H 2 Dissolve O in water to make a 0.5mol / L Fe element solution; take 0.1mol of Cu(NO 3 ) 2 ·6H 2 O is dissolved in water to make a 0.5mol / L Cu element solution; 0.05mol KNO 3 Dissolve in water to make 30wt% K element solution; mix the above three solutions together to make solution I; take 3mol of nano-ZrO 2 Add to the above solution I and stir to obtain slurry II; heat slurry II to 80°C in a water bath at 80°C, adjust the pH value of the slurry to 4 with ammonia water with a concentration of 25wt%, to obtain slurry III, adjust the slurry The solid content of the material reaches 35% to obtain slurry IV; the slurry IV is spray-dried and formed, the inlet temperature of the sprayer is 300°C, and the outlet temperature is 170°C; then roasted at a roasting temperature of 550°C for 2 hours to obtain catalyst particles , and its composition is: Fe 100 Cu 10 K 5 Zr 300 o x .

[0054] 2) Catalyst evaluati...

Embodiment 3

[0070] 1) Catalyst preparation:

[0071] Take 1mol of Fe(NO 3 ) 3 9H 2 Dissolve O in water to make a 0.5mol / L Fe element solution; take 0.1mol of Cu(NO 3 ) 2 ·6H 2 O is dissolved in water to make a 0.5mol / L Cu element solution; 0.05mol NaNO 3 Dissolve in water to form a 30wt% Rb element solution; mix the above three solutions together to form solution I; take 3mol of nano-TiO 2 Add to the above solution I and stir to obtain slurry II; heat slurry II to 80°C in a water bath at 80°C, adjust the pH value of the slurry to 5 with ammonia water with a concentration of 25wt%, to obtain slurry III, adjust the slurry The solid content of the material reaches 35%, and the slurry IV is obtained; the slurry IV is spray-dried and molded, the inlet temperature of the sprayer is 320°C, and the outlet temperature is 190°C; then roasted, the roasting temperature is 600°C, and the roasting time is 3h, and the catalyst particles are obtained. , and its composition is: Fe 100 Cu 10 Na 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com