A kind of preparation method of medical protective clothing fabric

A technology for protective clothing and fabrics, which is applied in the field of preparation of medical protective clothing fabrics, can solve the problems that the advantages of rutile titanium dioxide cannot be well utilized, and achieve the effect of reducing temperature and increasing comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The medical protective clothing fabric provided in this embodiment is prepared through the following steps:

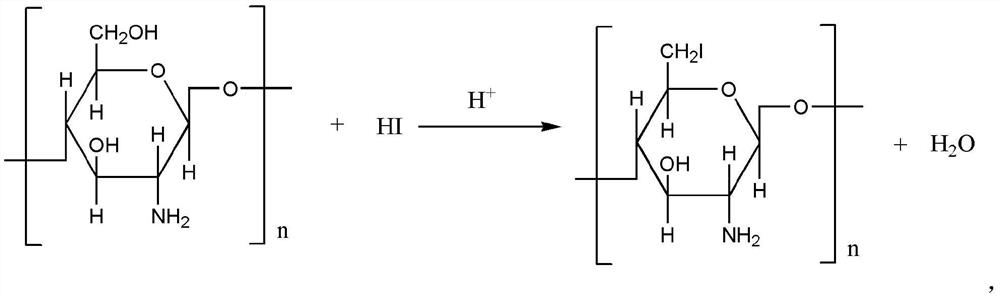

[0034] (1) Dissolve chitosan and sulfuric acid in water, add them into a three-necked flask, heat to 50°C under stirring and maintain a constant temperature, and add the HI aqueous solution dropwise to the three-necked flask at a speed of 5 mL / min, and the dropwise addition is completed. Then, the temperature was kept constant for 1 hour, and then the temperature was lowered to -8 °C to obtain light yellow crystal A, in which chitosan, H 2 SO 4 The mass ratio of , HI and water is 1:0.6:0.3:4, which has the following reaction equation:

[0035]

[0036] However, n is 30-60.

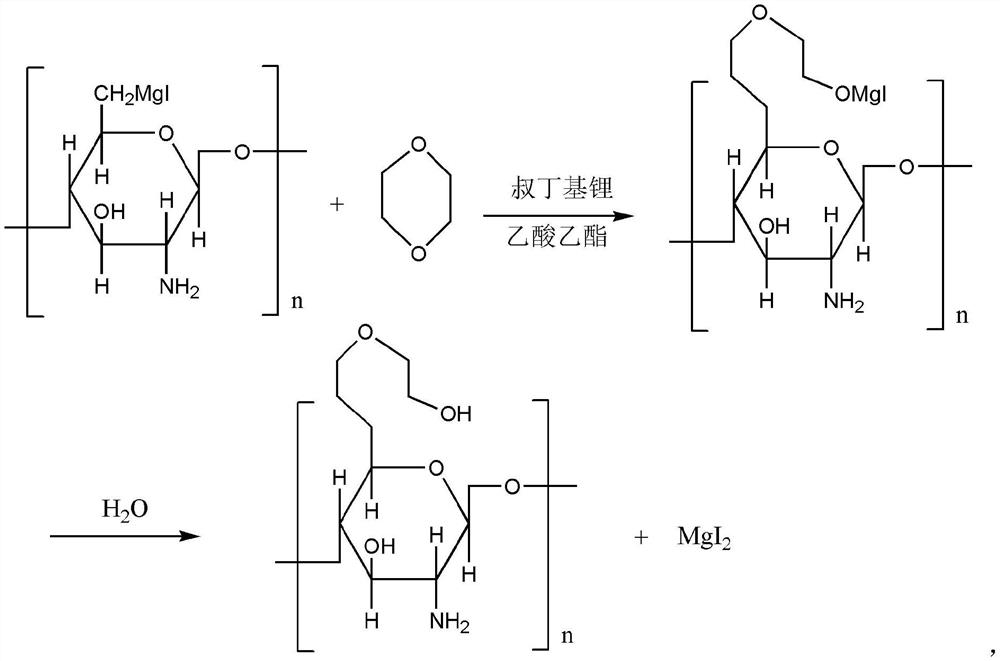

[0037] (2) Dissolve crystal A in ether, cut the newly cut metal magnesium into small pieces, add it to ether solvent, stir at room temperature for 3 hours, then distill off the solvent at 30°C, and heat the remaining solution to 60°C, The filtrate is then cooled to -5°C to obtain solid...

Embodiment 2

[0045] The medical protective clothing fabric provided in this embodiment is prepared through the following steps:

[0046] (1) Dissolve chitosan and sulfuric acid in water, add them into a three-necked flask, heat to 55°C under stirring and maintain a constant temperature, and add the HI aqueous solution dropwise to the three-necked flask at a speed of 5.5ml / min. After completion, the reaction was performed at a constant temperature for 1.5 hours, and then the temperature was lowered to -9°C to obtain light yellow crystal A. Among them, chitosan, H 2 SO 4 The mass ratio of , HI and water is 1:0.7:0.35:4.5.

[0047] (2) Dissolve crystal A in ether, cut the newly cut metal magnesium into small pieces, add it to ether solvent, stir at room temperature for 3.5 hours, then distill off the solvent at 35°C, and heat the remaining solution to 65°C, The filtrate was then cooled to -6°C to obtain solid B. Wherein, the mass ratio of crystal A, magnesium and ether is 1:0.085:4.5.

...

Embodiment 3

[0052] The medical protective clothing fabric provided in this embodiment is prepared through the following steps:

[0053] (1) Dissolve chitosan and sulfuric acid in water, add them into a three-necked flask, heat to 60°C under stirring and maintain a constant temperature, and add the HI aqueous solution dropwise to the three-necked flask at a speed of 6ml / min, and the dropwise addition is completed. After that, the reaction was performed at a constant temperature for 2 hours, and then the temperature was lowered to -10°C to obtain light yellow crystal A. Among them, chitosan, H 2 SO 4 The mass ratio of , HI and water is 1:0.8:0.4:5.

[0054] (2) Dissolve crystal A in ether, cut the newly cut metal magnesium into small pieces, add it to ether solvent, stir at room temperature for 4 hours, then distill off the solvent at 35°C, and heat the remaining solution to 70°C, The filtrate was then cooled to -7°C to obtain solid B. The mass ratio of crystal A, magnesium and ether is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com