Antibacterial cement concrete and preparation method thereof

A cement concrete and cement technology, applied in the field of building materials, can solve the problems of reducing photocatalytic performance, affecting the service life of cement concrete, unable to guarantee dispersibility, etc. Application, the effect of improving the resistance to bacterial erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

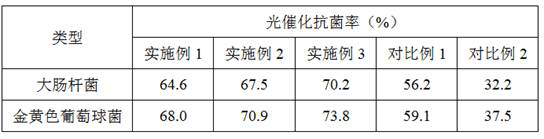

Examples

preparation example Construction

[0030] A kind of preparation method of antibacterial cement concrete, carry out as follows:

[0031] Step 1: Sieve natural coarse aggregate and artificial coarse aggregate to obtain natural coarse aggregate and artificial coarse aggregate;

[0032]Step 2: In the interval of particle size (4.75, 16mm], according to the weight ratio of natural coarse aggregate and artificial coarse aggregate 1:0.25~0.35, weigh the natural coarse aggregate and artificial coarse aggregate respectively, and mix them evenly Obtain the coarse aggregate in the first interval; in the interval of particle size (16, 26.5mm], according to the weight ratio of natural coarse aggregate and artificial coarse aggregate 1:0.15~0.25, weigh the natural coarse aggregate and artificial coarse aggregate respectively. Aggregate, and mixed evenly to obtain coarse aggregate in the second interval; in the interval of particle size (26.5, 37.5mm], according to the weight ratio of natural coarse aggregate and artificial ...

Embodiment 1

[0046] In this example, the raw material ratio of antibacterial cement concrete by weight is: 15 parts of ordinary portland cement, 0.7 part of metakaolin, 45 parts of quartz sand, 90 parts of coarse aggregate, 0.02 part of antibacterial agent, 8 parts of deionized water share;

[0047] The coarse aggregate is formed by mixing natural coarse aggregate and artificial coarse aggregate; the raw material ratio of artificial coarse aggregate in parts by weight is: 21 parts of cement, 1.8 parts of metakaolin, 60 parts of quartz sand, and 0.16 parts of basalt fiber , 0.035 parts of antibacterial agent, 11 parts of deionized water, and the natural coarse aggregate is limestone gravel.

[0048] The antibacterial agent is composed of an antibacterial main material and an antibacterial auxiliary material; the antibacterial main material is an equal mass combination of any two of nano-titanium dioxide, nano-graphite carbon nitride, and nano-zirconia; the antibacterial auxiliary material i...

Embodiment 2

[0058] In this example, the raw material ratio of antibacterial cement concrete by weight is: 15 parts of ordinary portland cement, 0.7 part of metakaolin, 45 parts of quartz sand, 90 parts of coarse aggregate, 0.02 part of antibacterial agent, 8 parts of deionized water share;

[0059] The coarse aggregate is formed by mixing natural coarse aggregate and artificial coarse aggregate; the raw material ratio of artificial coarse aggregate in parts by weight is: 21 parts of cement, 1.8 parts of metakaolin, 60 parts of quartz sand, and 0.16 parts of basalt fiber , 0.035 parts of antibacterial agent, 11 parts of deionized water, and the natural coarse aggregate is limestone gravel.

[0060] The antibacterial agent is composed of an antibacterial main material and an antibacterial auxiliary material; the antibacterial main material is an equal mass combination of any two of nano-titanium dioxide, nano-graphite carbon nitride, and nano-zirconia; the antibacterial auxiliary material i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com