Low-color-difference fiber-added nylon and forming process thereof

A molding process, nylon technology, applied in the production of bulk chemicals, etc., can solve the problems of large color difference, reduce floating fibers on the surface of fiber-added nylon, reduce surface floating fibers, improve molding quality, and improve chemical bonding and physical support. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

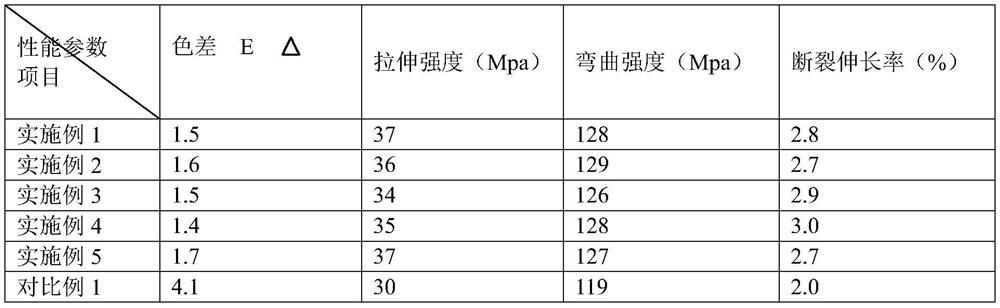

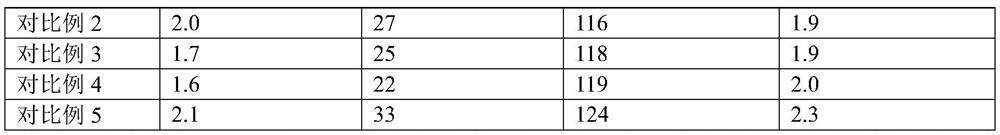

Examples

preparation example Construction

[0042] The preparation method of described modified toner is:

[0043] 1) Coating isolation layer: Pour melamine and formaldehyde into the reaction vessel at a molar ratio of 1:2.5-3, react in a water bath at 65-70°C for 2.5-3 hours, add coloring agent and absolute ethanol to the reaction vessel, Add deionized water, adjust the pH value to 5-6 with hydrochloric acid, heat at 80-85°C for 1-2h, filter to obtain the precipitate, wash it with deionized water, dry at 120-130°C for 1-2h to obtain melamine formaldehyde resin Coated toner; the mass ratio of added toner, absolute ethanol and melamine is 2:3-4:1;

[0044] 2) Prepare the porous layer: add the melamine-formaldehyde resin-coated toner to the cellulose solution with a concentration of 12-15wt%, stir evenly and perform ultrasonic dispersion, and then place the dispersion solution in an environment of -6 to -2°C Freeze for 48-60 hours; then thaw the frozen product at room temperature to obtain cellulose hydrogel, and use eth...

Embodiment 1

[0057] A low-chromatic-difference fiber-added nylon. The components of the low-color-difference fiber-added nylon are as follows in terms of mass: 65 parts of nylon, 18 parts of modified glass fibers with a length of 4 mm, 3 parts of polyacrylic acid, 2 parts of titanium dioxide, and quartz powder. 2 parts, 4 parts of modified toner, 1.5 parts of viscosity reducer.

[0058] The preparation method of described modified toner is:

[0059] 1) Coating isolation layer: Pour melamine and formaldehyde into the reaction vessel at a molar ratio of 1:2.8, react in a water bath at 68°C for 2.8 hours, add coloring agent and absolute ethanol to the reaction vessel, and add deionized water, Use hydrochloric acid to adjust the pH value to 5.5, heat at 82°C for 1.5h, filter the precipitate, wash it with deionized water, and dry it at 125°C for 1.5h to obtain the melamine-formaldehyde resin-coated toner; the added toner, The mass ratio of absolute ethanol to melamine is 2:3.5:1;

[0060] 2) ...

Embodiment 2

[0073] A low-chromatic-difference fiber-added nylon. The components of the low-color-difference fiber-added nylon are as follows in terms of mass fractions: 62 parts of nylon, 18 parts of modified glass fibers with a length of 3.5 mm, 2.5 parts of polyacrylic acid, 1.5 parts of titanium dioxide, quartz 1.5 parts of powder, 3.5 parts of modified coloring agent, and 1.2 parts of viscosity reducer.

[0074] The preparation method of described modified toner is:

[0075] 1) Coating isolation layer: Pour melamine and formaldehyde into the reaction vessel at a molar ratio of 1:2.6, react in a water bath at 66°C for 2.8 hours, add coloring agent and absolute ethanol to the reaction vessel, add deionized water, Adjust the pH value to 5.2 with hydrochloric acid, heat at 81°C for 1.2h, filter the precipitate, wash it with deionized water, and dry it at 122°C for 1.2h to obtain the melamine-formaldehyde resin-coated toner; the added toner, The mass ratio of absolute ethanol to melamine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com