Fiber aid for slope spray-seeding greening, preparation method and matrix

A fiber aid and slope technology, applied in the field of slope ecological protection matrix, can solve the problems that the amount of plant fiber affects the mixing efficiency of the matrix, and achieve the effects of improving long-term stability, reducing dosage, and improving anti-scouring performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

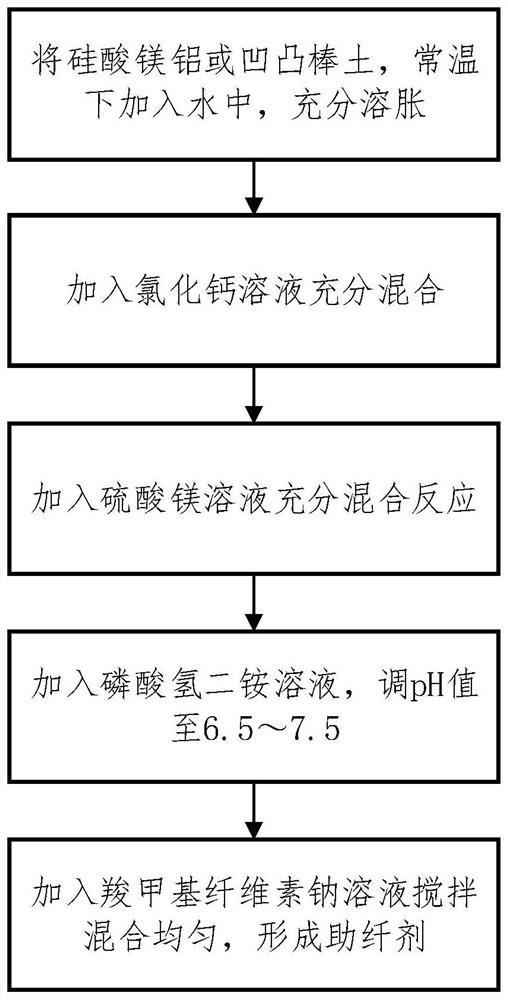

[0031] combine figure 1 , the preparation method of fiber aid, comprises the following steps:

[0032] (1) Add 90-100 parts by mass of magnesium aluminum silicate (or attapulgite) to 500-600 parts by mass of water at room temperature, and stir at a medium speed for 3-4 hours to fully swell to obtain Group A.

[0033] (2) Dissolve 20-25 parts by mass of calcium chloride in 30-35 parts by mass of water, add to group A, and mix thoroughly to obtain group B.

[0034] (3) Dissolve 35-40 parts by mass of magnesium sulfate in 70-80 parts by mass of water, add to group B, fully mix and react to obtain group C.

[0035] (4) Dissolve 10-30 parts by mass of diammonium hydrogen phosphate with 20-60 parts by mass of water, add to group C, fully mix and react, and adjust the pH value to 6.5-7.5 to obtain group D.

[0036] (5) Dissolve 1-2 parts by mass of carboxymethylcellulose sodium in 10-20 parts by mass of water, add to group D, stir and mix evenly to form a fiber aid.

[0037] Magne...

Embodiment 1

[0042] 1. Preparation of fiber aid

[0043] (1) Add 90 parts by mass of magnesium aluminum silicate (or attapulgite) to 500 parts by mass of water at room temperature, and stir at a medium speed for 3 to 4 hours to fully swell.

[0044] (2) Dissolve 21 parts by mass of calcium chloride in 30 parts by mass of water, and mix well after adding.

[0045] (3) Dissolve 35 parts by mass of magnesium sulfate with 73 parts by mass of water, mix and react fully after adding, to obtain C.

[0046] (4) Dissolve 15 parts by mass of diammonium hydrogen phosphate with 40 parts by mass of water, mix and react fully after adding, and adjust the pH value to 6.8.

[0047] (5) Dissolve 1.2 parts by mass of sodium carboxymethyl cellulose with 12 parts by mass of water, add and stir to mix evenly to form a fiber aid.

[0048] 2. To form a matrix, use 100g of fiber aid per square meter of soil and 10g / m of water retaining agent 2, granule agent (main components: sodium polyacrylate, polyacrylamid...

Embodiment 2

[0052] 1. Preparation of fiber aid

[0053] (1) Add 98 parts by mass of magnesium aluminum silicate (or attapulgite) to 550 parts by mass of water at room temperature, and stir at a medium speed for 3 to 4 hours to make it fully swell.

[0054] (2) Dissolve 25 parts by mass of calcium chloride in 35 parts by mass of water, and mix well after adding.

[0055] (3) Dissolve 40 parts by mass of magnesium sulfate with 75 parts by mass of water, mix and react fully after adding, to obtain C.

[0056] (4) Dissolve 25 parts by mass of diammonium hydrogen phosphate in 50 parts by mass of water, mix and react fully after adding, and adjust the pH value to 6.9.

[0057] (5) Dissolve 1.8 parts by mass of sodium carboxymethyl cellulose with 18 parts by mass of water, add and stir to mix evenly to form a fiber aid.

[0058] 2. To form a matrix, use 200g of fiber-aiding agent per square meter of soil, and 10g / m of water-retaining agent 2 , fiber aid 150g / m 2 , granule agent 30g / m 2 , pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com