Lignite comprehensive utilization microwave extraction environment-friendly device and process

An environmental protection device and microwave technology, applied in the field of coal chemical industry, can solve the problems of high process energy consumption, violation of energy conservation and emission reduction, low ignition point of lignite, and destruction of valuable components of lignite.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

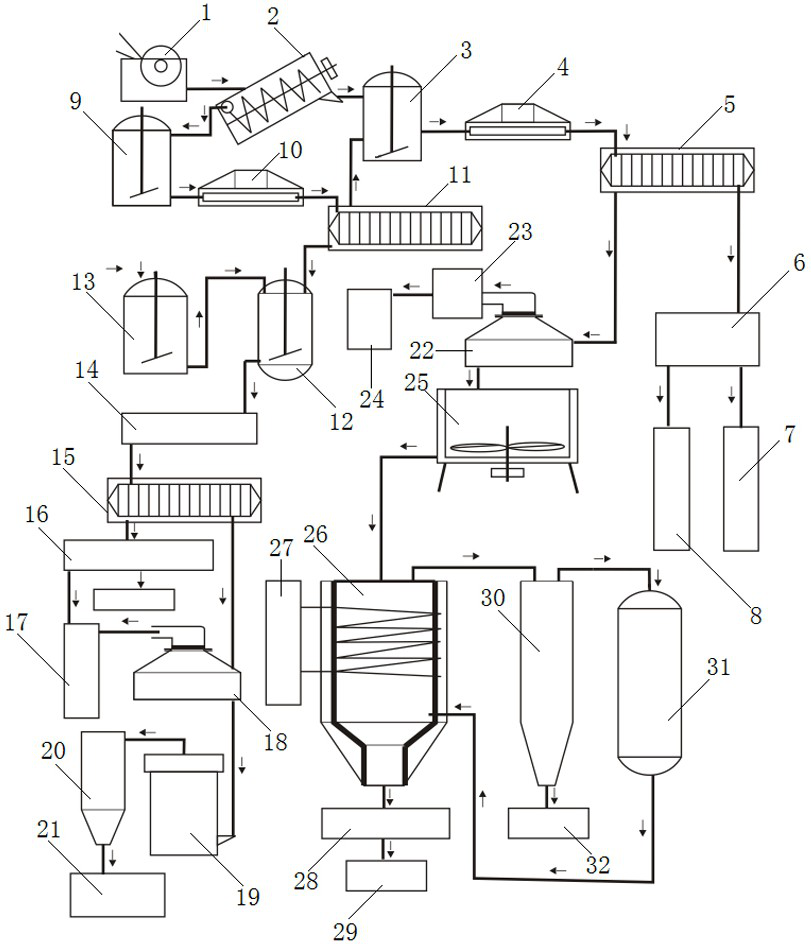

[0039]The lignite is pulverized by adding tap water with 5 to 9 times the quality of the lignite through the wet pulverizer 1, and the ore slurry is classified by the spiral classifier 2, and the fine slurry is sent to the No. 11 filter residues are combined and sent to the No. 1 storage tank 3, and the concentration of the pulp is adjusted with tap water at a solid-to-liquid ratio of 1:5~8, and then ammonium chloride with a total amount of 3~7% of the pulp is added to stir and dissolve, and the flow rate is adjusted and sent to No. 1 storage tank 3. No. microwave extractor 4 controls the extraction temperature at 90-95 degrees Celsius to extract montan wax, and the extraction time is 30-60 minutes. The extracted pulp enters the No. 1 plate and frame filter through a pipeline equipped with a water bath jacket at a constant temperature of 75-85 degrees Celsius 5. Carry out thermal filtration, the filter residue is sent to No. 2 microwave drier 22, and the filtrate is sent to No....

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com