Method for purifying industrial by-product salts

A technology of industrial by-products and purification methods, which is applied to the purification of alkali metal halides and alkali metal chlorides, etc., and can solve the problem of easy adhesion of industrial by-product salts on the inner wall of incineration equipment, uneven heating of industrial by-product salts, and equipment Can not be used normally and other problems, to achieve the effect of low heating temperature, harmless treatment, fast reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

[0097] Embodiment 4 industrial by-product salt purification method

[0098] The difference from Example 1 is: the industrial by-product salt is ground and pulverized to 10 meshes; the stirring speed is 200 rpm; is 800°C. The aeration time was 5 minutes, and the product 4 was obtained # .

[0099] Embodiment 5 industrial by-product salt purification method

[0100] The difference from Example 1 is that the stirring speed is 50 rpm; the oxygen-enriched hot air is fed in at a volume ratio of hot air to oxygen of 1:0.1, and the temperature of the oxygen-enriched hot air is 650°C. Aeration time is 1 hour, product 5 is obtained # .

[0101] Embodiment 6 industrial by-product salt purification method

[0102] The difference with Example 1 is: the temperature of the oxygen hot air is 450°C, and the product 6 is obtained # .

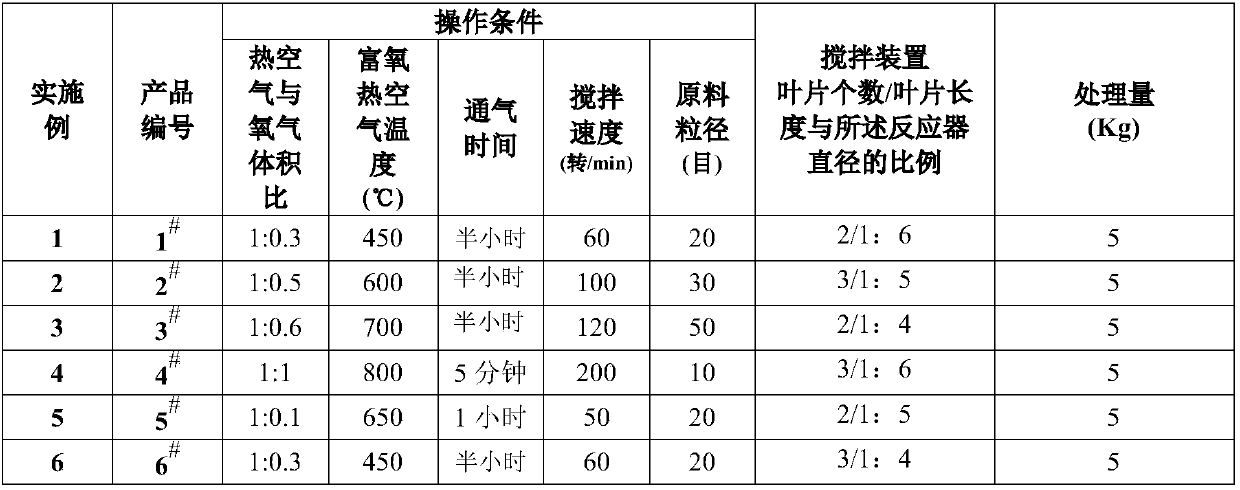

[0103] The resulting product 1 # ~6 # The operating conditions are shown in Table 1.

[0104] Table 1

[0105]

Embodiment 7

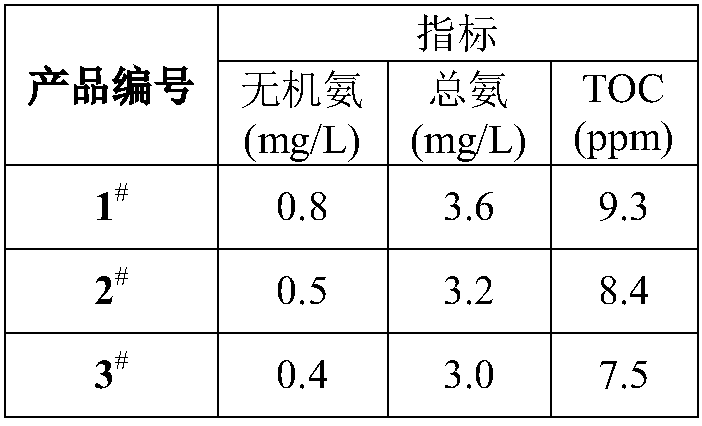

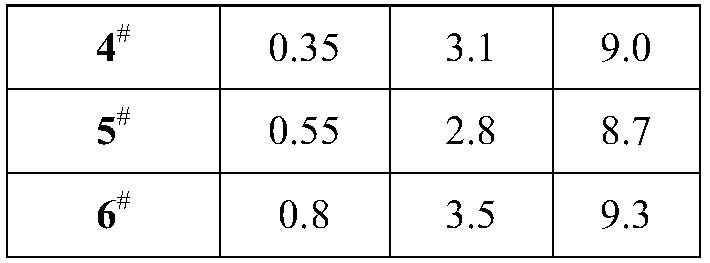

[0106] Example 7 Product 1 # ~6 # Determination of inorganic ammonia content, total ammonia content and TOC (total organic carbon) content

[0107] The method for determining the content of inorganic ammonia is Nessler's reagent spectrophotometry. Ammonia nitrogen in the form of free ammonia or ammonium ions reacts with Nessler's reagent to form a light reddish-brown complex. The absorbance of the complex is proportional to the content of ammonia nitrogen. Absorbance was measured at a wavelength of 420 nm.

[0108] The determination method of total ammonia content is alkaline potassium persulfate digestion ultraviolet spectrophotometry. At 120-124 ° C, alkaline potassium persulfate solution converts the nitrogen of nitrogen-containing compounds in the sample into nitrate. Absorbance was measured at 220nm and 275nm, respectively.

[0109] The TOC content determination method is measured by a TOC analyzer. The total organic carbon in the sample is oxidized to carbon dioxide, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com