Dual-mode blowback deashing device for blast furnace dry dedusting cloth bag

A technology of dry dust removal and dust removal device, which is applied in the direction of dust collector and process efficiency improvement, etc. It can solve the problems of high maintenance cost, high pressure difference of bag, affecting system production, etc., and achieve the effect of energy saving and long life of bag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

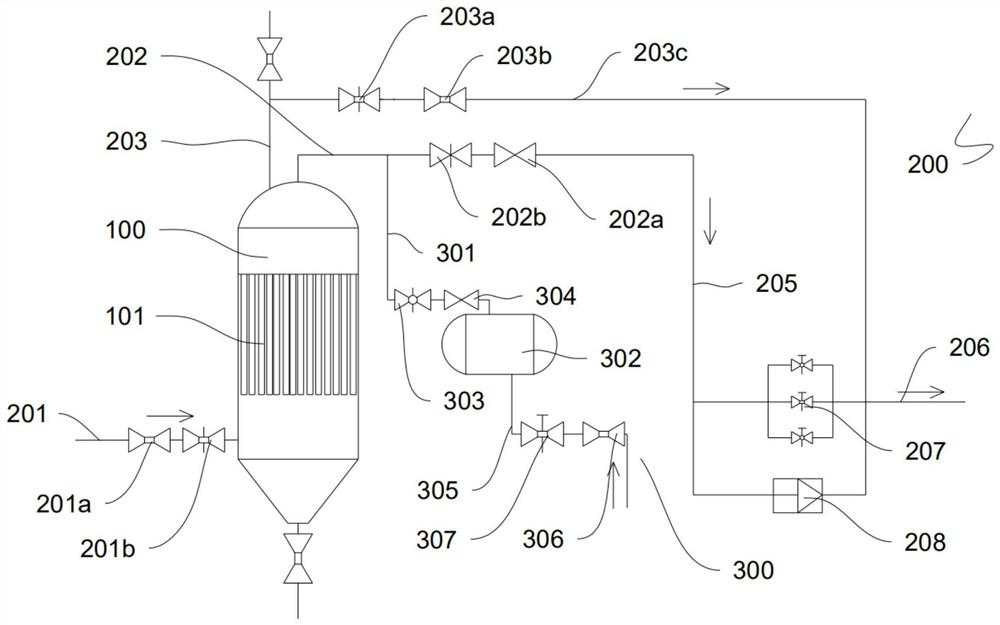

[0025] refer to figure 1 , which is the first embodiment of the present invention, this embodiment provides a dual-mode back-blowing soot cleaning device for dry dust removal bag for blast furnace, the dual-mode back-blowing soot cleaning device for dry dust removal bag for blast furnace includes a box assembly 100, a clean gas Ash cleaning assembly 200 and nitrogen blowback assembly 300, wherein the box assembly 100 includes a dust removal bag 101 placed in the box assembly 100, and a clean gas cleaning assembly 200 connected to the box assembly 100;

[0026] The nitrogen blowback assembly 300 is connected to the box assembly 100 and switched to use with the clean gas cleaning assembly 200 .

[0027] Based on the above, blast furnace dry dedusting is an energy-saving and environmentally friendly dedusting process. After dry dedusting, the blast furnace gas has a low dust content and can greatly increase the power generation capacity of the residual pressure of the gas. The en...

Embodiment 2

[0030] refer to figure 1 , is the second embodiment of the present invention, which is different from the first embodiment in that: the clean gas cleaning assembly 200 includes a raw gas branch pipe 201 connected to the dust bag 101, and the raw gas branch pipe 201 is provided with a first gas butterfly valve 201a and the first gas blind valve 201b, the first gas butterfly valve 201a is used for the switch control of the low-pressure pipeline medium, and rotates around its own axis in the valve body, so as to achieve the purpose of opening and closing or adjustment, the first gas blind valve The plate valve 201b is an electric blind plate valve, which is a gate valve for electrically cutting off the gas medium.

[0031] The clean gas cleaning assembly 200 also includes a clean gas branch pipe 202 and a gas pressure relief pipe 203 communicating with the upper part of the box assembly 100 , and the clean gas branch pipe 202 communicates with a high-pressure clean gas main pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com