Composite foundation structure of offshore wind power single pile, supporting disc and small suction barrels and construction method of composite foundation structure

An offshore wind power and composite foundation technology, applied in infrastructure engineering, protective devices, buildings, etc., can solve problems such as limited anti-wind and wave erosion and anti-overturning capabilities, improve horizontal bearing capacity and anti-overturning ability, and reduce engineering costs , High construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

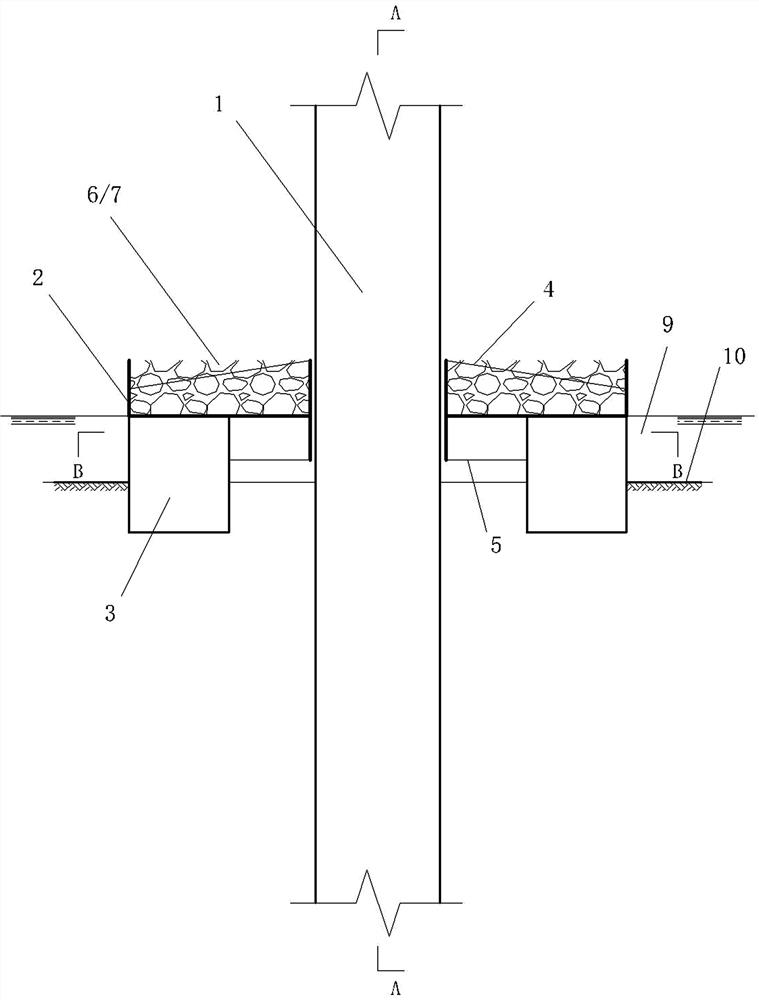

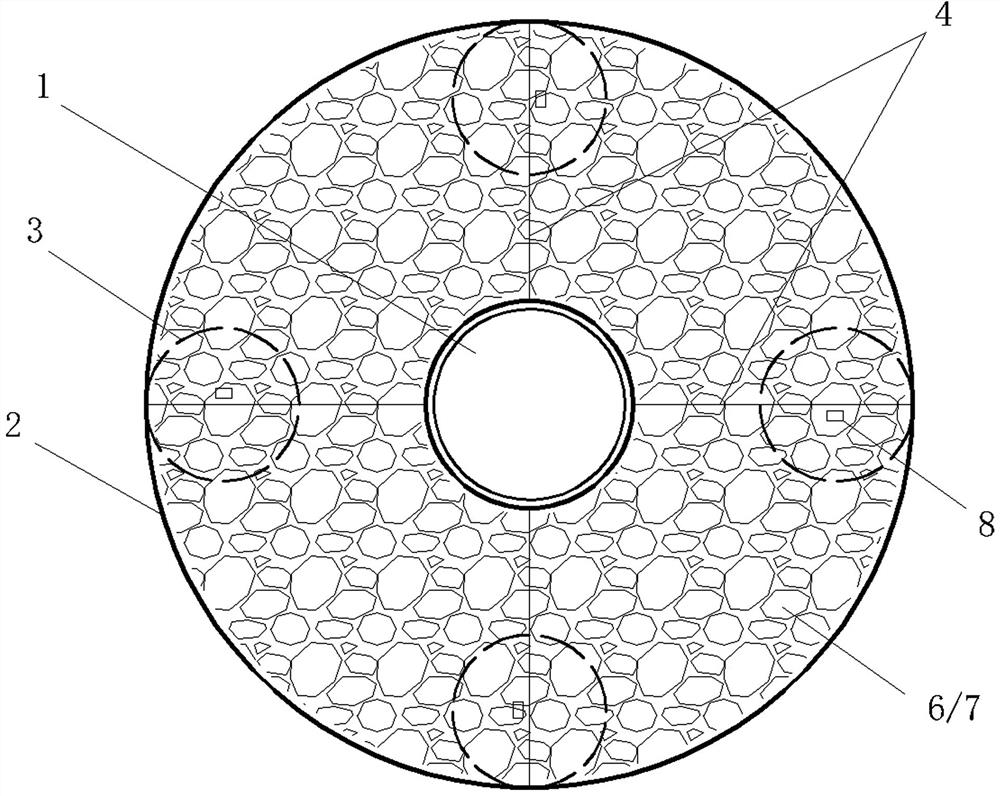

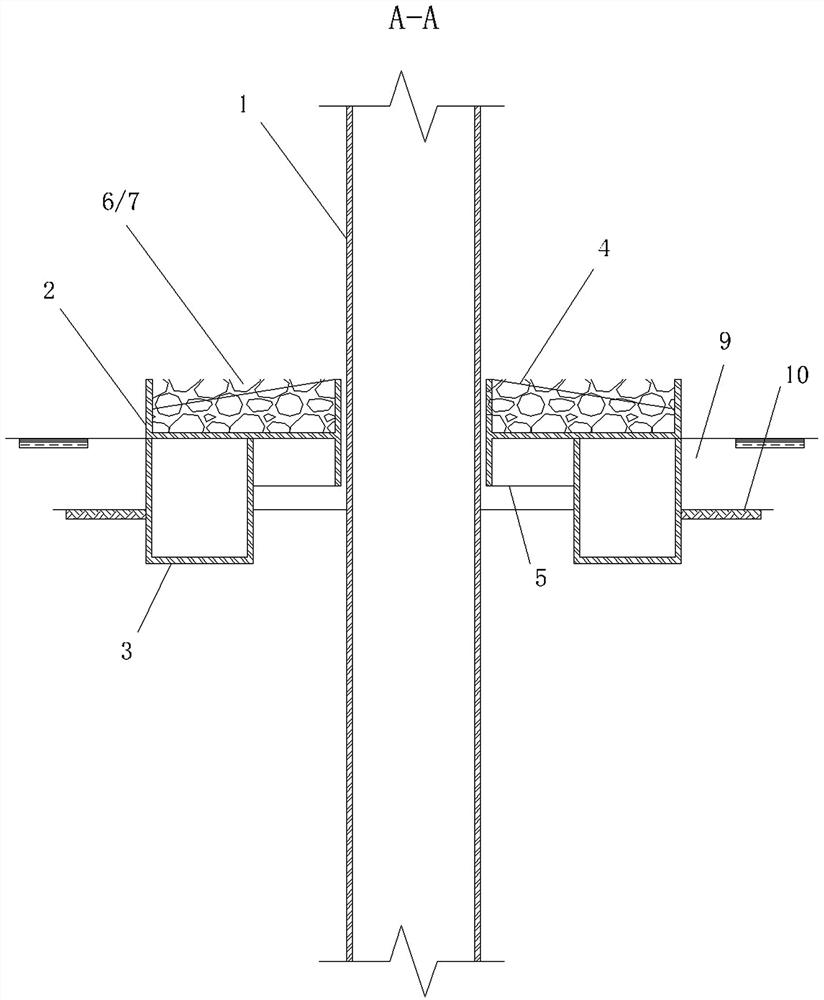

[0041] see Figure 1-6 , a composite foundation structure of an offshore wind power single pile, a support plate and a small suction barrel, which includes a steel pipe pile 1, a support plate 2 and a small suction barrel 3; the outer wall of the steel pipe pile 1 is connected to the inner wall of the support plate 2 The support plate 2 and the steel pipe pile 1 are concentrically arranged; the support plate 2 is provided with a first rib 4 inside; the support plate 2 is provided with a small suction bucket 3 and a second rib 5 at the bottom. There are two possible construction methods as follows:

[0042] One is to first drive the steel pipe pile 1 to the target depth; then insert the supporting plate 2 and the overall structure of the small suction bucket 3 from the top of the steel pipe pile 1, and make the bottom of the small suction bucket 3 approach or touch the bottom of the seabed through its own weight. The surface of the silt layer 9; through the suction device 8, t...

Embodiment 2

[0049] see Figure 1-6 , In this embodiment, a first rib plate 4 is manufactured inside the support plate 2, and the rib plate may adopt a trapezoidal or rectangular shape. The two parallel sides of the first rib 4 are respectively fixedly connected with the inner wall and the outer wall of the supporting plate 2 ; there are a plurality of the first ribs 4 , and they are evenly distributed inside the supporting plate 2 . Adopting the first rib 4, on the one hand, it increases the overall strength of the supporting plate 2; on the other hand, a plurality of fan-shaped areas are formed inside the supporting plate 2, which provides ample space for the arrangement of suction devices, rockfill dumping or concrete pouring. space.

[0050]Further, the diameter of the support plate 2 is 25-40m. The purpose is to obtain the best pile foundation support effect.

[0051] Further, the number of first ribs 4 inside the support plate is 3-8. The purpose is to obtain the best structural ...

Embodiment 3

[0053] see Figure 1-6 , in this embodiment, a small suction bucket 3 and a second rib 5 are manufactured at the bottom of the support plate 2 . The top of the small suction bucket 3 is connected to the bottom of the support plate 2; The second rib 5 can be trapezoidal or rectangular, and the two parallel sides of the second rib 5 are fixedly connected with the inner wall of the support plate 2 and the outer wall of the small suction bucket 3 respectively, which strengthens the composite foundation.

[0054] Further, the diameter of the small suction barrel 3 is 6-10m. The purpose is to obtain the best pile foundation support effect.

[0055] Further, the number of the second ribs 5 at the bottom of the support plate and the number of the small suction barrels 3 are kept the same, ranging from 3 to 6. The purpose is to obtain the best structural reinforcement effect and pile foundation support effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com