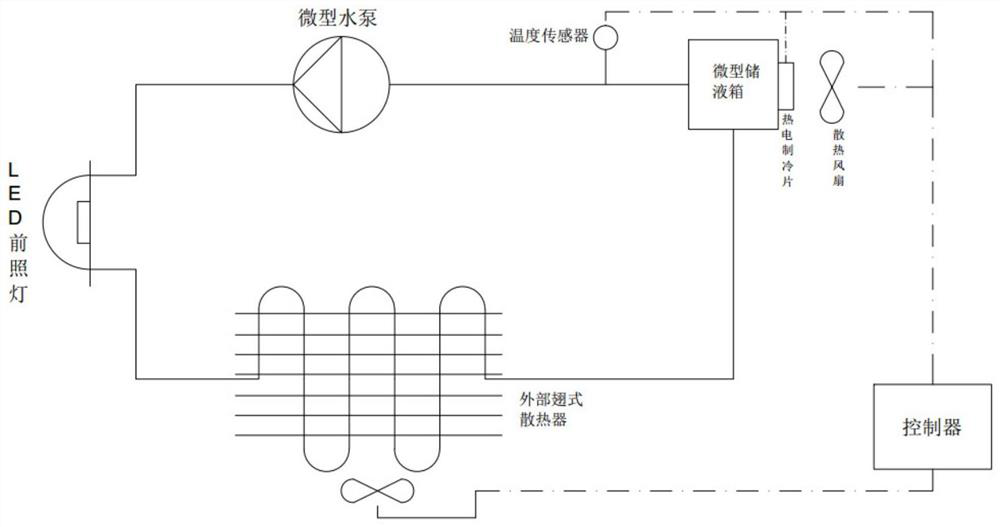

Vehicle LED lamp based on 3D printing and liquid cooling system thereof

A 3D printing, LED lamp technology, applied in the direction of headlights, cooling/heating devices of lighting devices, vehicle parts, etc., can solve the problems of complex porous media structure, waste of raw materials, high manufacturing cost, improve lighting effect and reduce installation. process, the effect of reducing material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A 3D printing-based radiator for LED lamps for vehicles, including a housing, a liquid injection port 121, a liquid outlet 122, a lamp fixing installation hole 123, a micro-spray high-pressure liquid inlet area 124, a micro-spray cooling chamber 125, and an intermediate jet plate 126, micro-spray holes 127, bottom cold plate 128, spherical through-hole porous medium 129, top cover plate 1210, spoiler column 1211, porous medium cooling channel 1212, porous medium liquid injection area 1213, cooling liquid output area 1214.

[0039]A lamp fixing installation hole 123 is opened on the shell, and the radiator 12 is installed on the outer bottom surface of the reflector cup through the lamp fixing installation hole 123 . A wiring hole 15 is also provided in the middle part of the housing axially, through which some cables required by the headlight can pass in and out. The shell includes a bottom cold plate 128 and a top cover plate 1210, and a cooling chamber is formed insid...

Embodiment 2

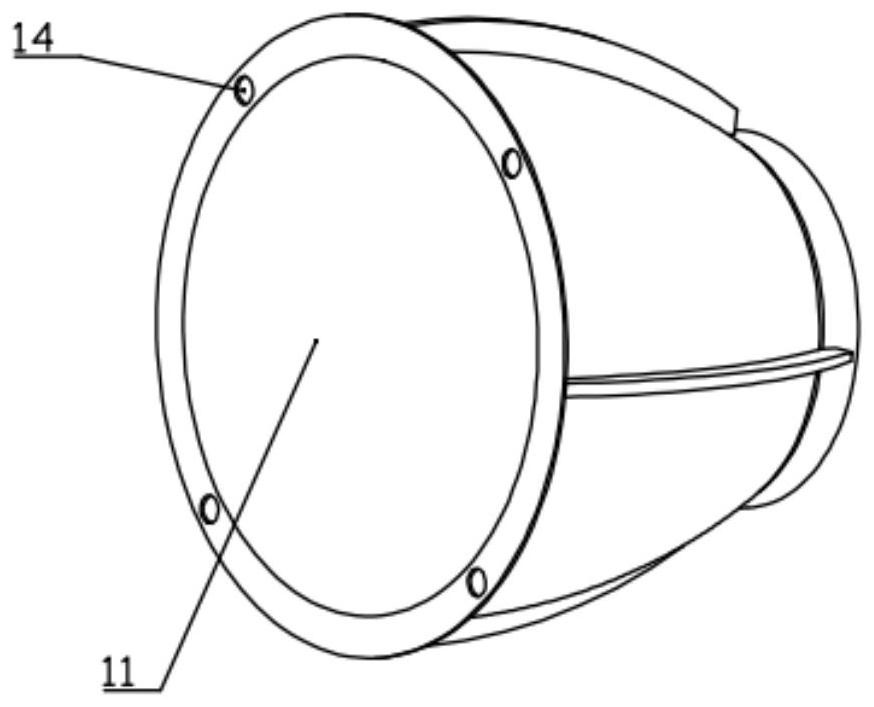

[0047] This embodiment also provides a 3D printing-based heat dissipation reflector cup for LED lamps for vehicles, which includes a cup body 11, and a radiator 12 is connected to the bottom surface of the cup body 11, and the radiator 12 adopts the radiator 12 in the first embodiment.

[0048] It also includes a plurality of ribs 13 connected to the cup body 11 , the plurality of ribs 13 are evenly distributed along the circumferential direction of the cup body 11 , and each rib 13 is arranged along the axial direction of the cup body 11 . During installation, the rib plate 13 is embedded into the corresponding slot of the car mounting frame. The rib plate 13 is used for positioning and strengthening, so that the whole reflector cup is embedded in the corresponding slot of the car mounting structure, preventing the car from reflecting light during driving. The vibration of the cup affects the lighting effect, and at the same time increases the intensity of the reflective cup. ...

Embodiment 3

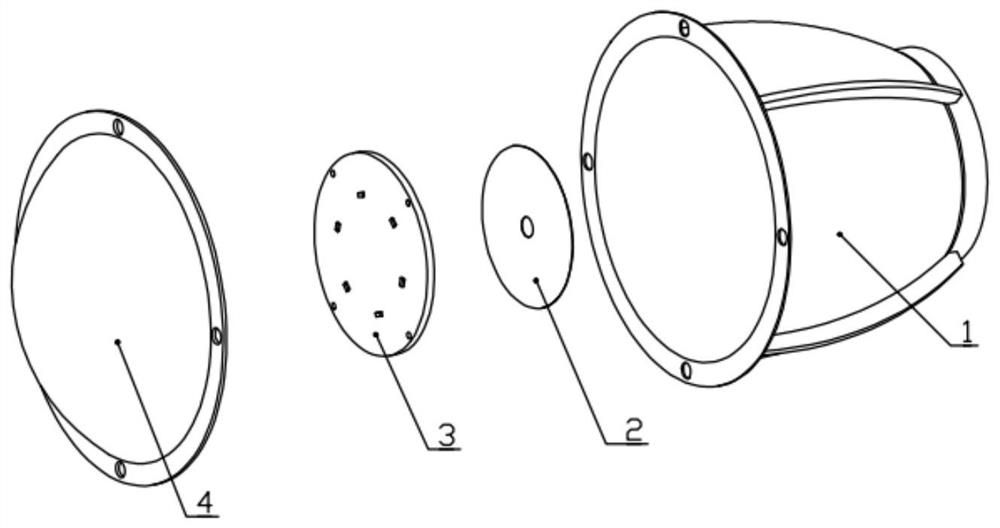

[0054] This embodiment also provides a 3D printing-based LED heat dissipation headlight for vehicles, including a heat dissipation reflector 1, an LED light source module 3 installed on the inner bottom of the heat dissipation reflector 1 through a heat-conducting silica gel 2, and a heat dissipation reflector 1 The light source lens 4 at the mouth of the cup and the heat dissipation reflector 1 adopt the heat dissipation reflector 1 of the second embodiment above.

[0055] A lens installation hole 14 is opened on the end surface of the heat dissipation reflector 1 near the light source lens 4 , and the light source lens 4 is installed on the heat dissipation reflector 1 through the lens installation hole 14 .

[0056] The inner bottom of the heat dissipation reflective cup 1 is provided with an LED light source installation hole 16 , and the LED light source module 3 is installed on the inner bottom of the heat dissipation reflective cup 1 through the LED light source installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com