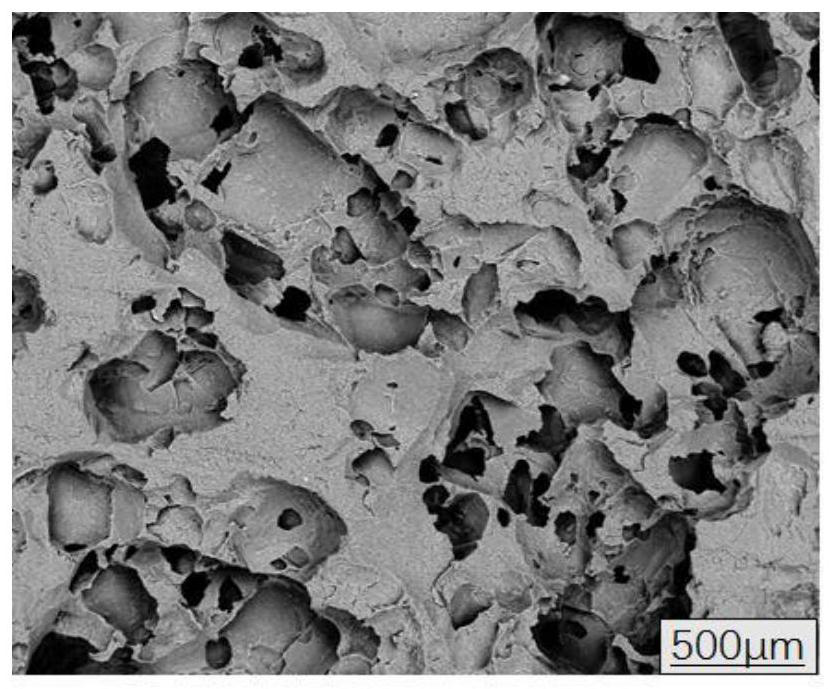

Preparation method of magnesium/hydroxyapatite porous composite material

A technology of porous composite materials and hydroxyapatite, which is applied in the field of preparation of biomedical materials, can solve the problems of uneven composition structure, cell toxicity, induced inflammation, etc., and achieve the effect of avoiding rapid degradation and HA decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Metal magnesium powder with a purity of 99.95-99.99% and a particle size of 10-20 μm and nano-hydroxyapatite with a purity of ≥99.9% and a particle size of 150-300 μm are used as raw materials, wherein magnesium powder and nano-hydroxyapatite According to the mass ratio of 1%:99% for proportioning.

[0032] (2) Put the powder weighed in step (1) into a stainless steel ball mill tank, put in an appropriate amount of stainless steel balls according to the ball-to-material ratio of 4:1, and evacuate it to 8Pa. The above process is carried out in a vacuum glove box Finished in middle; fixed on the planetary ball mill, ball milled at 200r / min for 2h; after the tank temperature dropped to room temperature, vacuum the tank again to 8Pa, and ball milled at 300 / min for 6h.

[0033] (3) Pour the slurry obtained in step (2) into a petri dish in a vacuum glove box, put the petri dish into a vacuum drying oven, the drying temperature in the oven is 35°C, and the vacuum degree is...

Embodiment 2

[0037](1) Using metal magnesium powder with a purity of 99.95-99.99% and a particle size of 10-20 μm and nano-hydroxyapatite with a purity of ≥99.9% and a particle size of 150-300 μm as raw materials, magnesium powder and nano-hydroxyapatite by The mass ratio is 3%: 97% for proportioning and weighing.

[0038] (2) Put the powder weighed in step (1) into a stainless steel ball mill jar, and put in an appropriate amount of stainless steel grinding balls according to the ball-to-material ratio of 3:1, wherein the mass ratio of the grinding balls is large ball: medium ball: small ball = 2:8:15, and vacuumize it to 9Pa, the above process is completed in a vacuum glove box; fix it on a planetary ball mill, and ball mill it at a speed of 200r / min for 2h; after the tank temperature drops to room temperature, The tank was evacuated to 9Pa again, and ball milled at a speed of 300 / min for 8 hours.

[0039] (3) Pour the slurry obtained in step (2) into a petri dish in a vacuum glove box,...

Embodiment 3

[0043] (1) Using metal magnesium powder with a purity of 99.95-99.99% and a particle size of 10-20 μm and nano-hydroxyapatite with a purity of ≥99.9% and a particle size of 150-300 μm as raw materials, magnesium powder and nano-hydroxyapatite by The mass ratio is 5%:95% for proportioning and weighing.

[0044] (2) Put the powder weighed in step (1) into a stainless steel ball mill jar, and put in an appropriate amount of stainless steel grinding balls according to the ball-to-material ratio of 3:1, wherein the mass ratio of the grinding balls is large ball: medium ball: small ball = 2:8:15, and vacuumize it to 10Pa, the above process is completed in a vacuum glove box; fix it on a planetary ball mill, and ball mill it at a speed of 300r / min for 2h; after the tank temperature drops to room temperature, The tank was evacuated to 10Pa again, and ball milled at a speed of 400 / min for 8 hours.

[0045] (3) Pour the slurry obtained in step (2) into a petri dish in a vacuum glove bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com