Optical fiber hydrogen-senstive sensor, preparation method and hydrogen leakage detection device

An optical fiber sensor and sensor technology, applied in the field of materials, can solve the problems of inconsistent color standards in human judgment, inability to instantly find leaks, and inability to detect subtle leaks, and achieve the effect of ensuring market size, reliable performance, and reduced production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

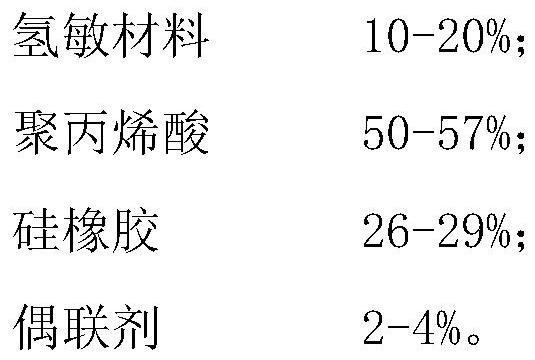

[0063] For the hydrogen-sensitive membrane provided in this embodiment, its raw material formula is shown in Table 1, wherein,

[0064] Titanium dioxide hydrogen sensitive material 15%;

[0065] Binder 85%.

Embodiment 2

[0067] For the hydrogen-sensitive membrane provided in this embodiment, its raw material formula is shown in Table 1, wherein,

[0068] Tungsten trioxide hydrogen sensitive material 15%;

[0069] Binder 85%.

Embodiment 3

[0071] For the hydrogen-sensitive membrane provided in this embodiment, its raw material formula is shown in Table 1, wherein,

[0072] Titanium dioxide hydrogen sensitive material 15%;

[0073] Polyacrylic acid 82%;

[0074] Coupling agent 3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com