Preparation method of transfer type heat conduction coating for LED lamp back plate

A thermally conductive coating, LED lamp technology, applied in coatings, devices for coating liquid on surfaces, epoxy resin coatings, etc. The effect of improving heat dissipation efficiency and speeding up heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

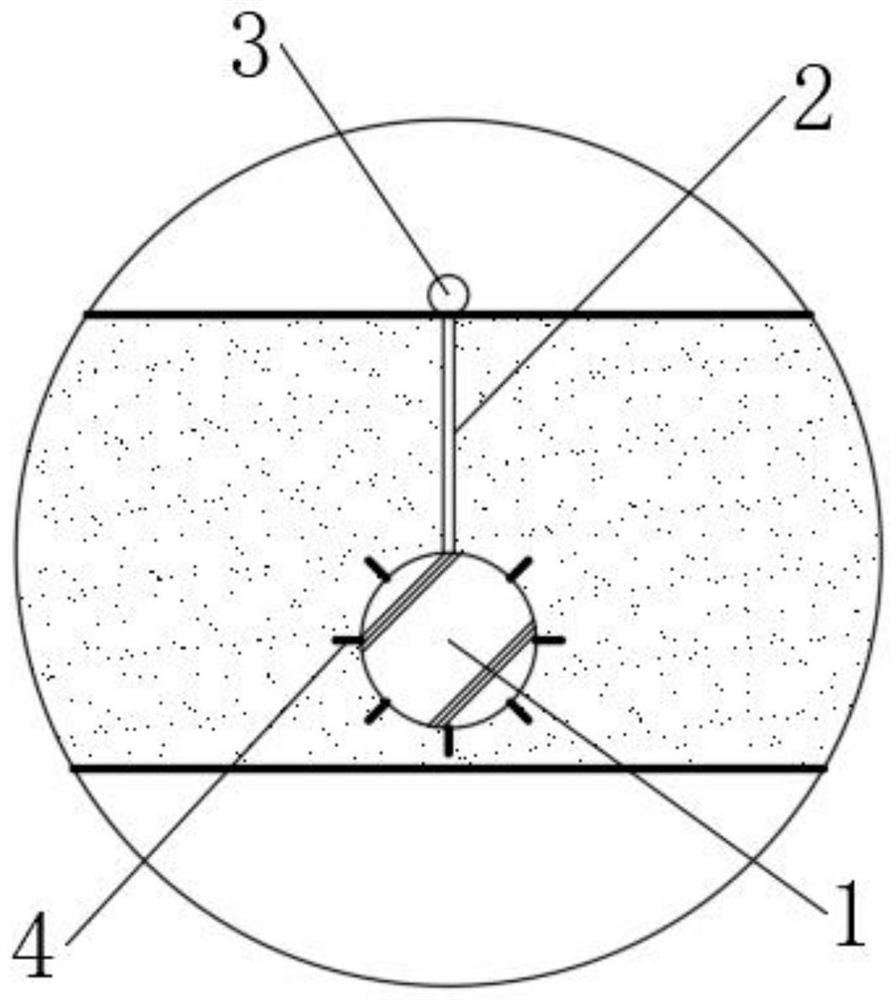

[0042] see figure 1 , a kind of preparation method of transferable heat-conductive coating for LED lamp backboard, comprises the following steps:

[0043] S1. Weigh 30 parts of acrylic resin, 10 parts of epoxy resin, 5 parts of aluminum nitride, 10 parts of thermal conductive monomer, 4 parts of graphite, 10-12 parts of butyl ester, 1 part of dispersant, and 0.5 parts of leveling agent according to the proportion After uniform mixing with 1 part of anti-settling agent, ultrasonically disperse to obtain thermal conductive coating;

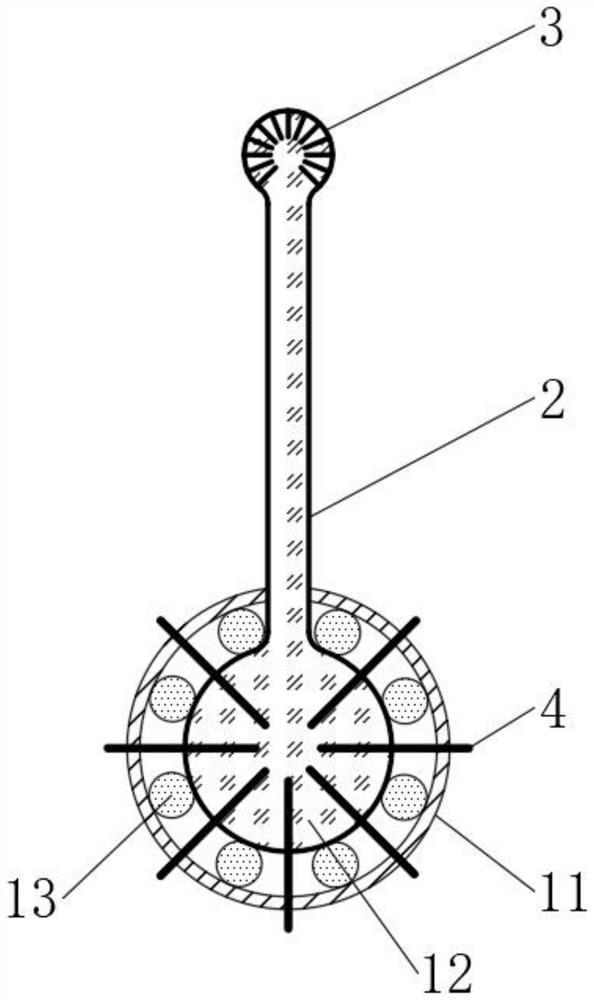

[0044] S2. Take the heat transfer ball accounting for 10% of the mass percentage of the heat-conducting paint, mix it with the heat-conducting paint, and apply it to the LED lamp backboard after vacuum defoaming;

[0045] S3. Use the magnetic plate to force the heat transfer ball to keep evenly "standing" in the heat-conducting coating, and at the same time, heat and cure the heat-conducting coating. The heating temperature is 120°C, and the curing...

Embodiment 2

[0055] see figure 1 , a kind of preparation method of transferable heat-conductive coating for LED lamp backboard, comprises the following steps:

[0056] S1. Weigh 40 parts of acrylic resin, 15 parts of epoxy resin, 8 parts of aluminum nitride, 12 parts of heat conducting monomer, 6 parts of graphite, 11 parts of butyl ester, 2 parts of dispersant, 1 part of leveling agent and After 1.5 parts of the precipitating agent are evenly mixed, ultrasonically disperse to obtain a thermally conductive coating;

[0057] S2. Take the heat transfer ball accounting for 20% of the mass percentage of the heat-conducting paint, mix it with the heat-conducting paint, and apply it to the LED lamp backboard after vacuum defoaming;

[0058] S3. Use the magnetic plate to force the heat transfer ball to keep evenly "standing" in the heat-conducting coating, and at the same time, heat and cure the heat-conducting coating. The heating temperature is 140°C, and the curing time is 75 minutes to obtai...

Embodiment 3

[0061] see figure 1 , a kind of preparation method of transferable heat-conductive coating for LED lamp backboard, comprises the following steps:

[0062] S1. Weigh 50 parts of acrylic resin, 20 parts of epoxy resin, 10 parts of aluminum nitride, 15 parts of heat conducting monomer, 8 parts of graphite, 12 parts of butyl ester, 3 parts of dispersant, 2 parts of leveling agent and After 2 parts of the precipitating agent are evenly mixed, ultrasonically disperse to obtain a thermally conductive coating;

[0063] S2. Take the heat transfer ball accounting for 30% of the mass percentage of the heat-conducting paint, mix it with the heat-conducting paint, and apply it to the LED lamp backboard after vacuum defoaming;

[0064] S3. Use the magnetic plate to force the heat transfer ball to keep evenly "standing" in the heat-conducting coating, and at the same time, heat and cure the heat-conducting coating. The heating temperature is 160°C, and the curing time is 90 minutes to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com