Protective cover plate and mobile terminal

A technology for protecting cover plates and soft adhesive layers. It is used in film/sheet adhesives, coatings, telephone communications, etc., and can solve the problems of low hardness and easy scratches.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

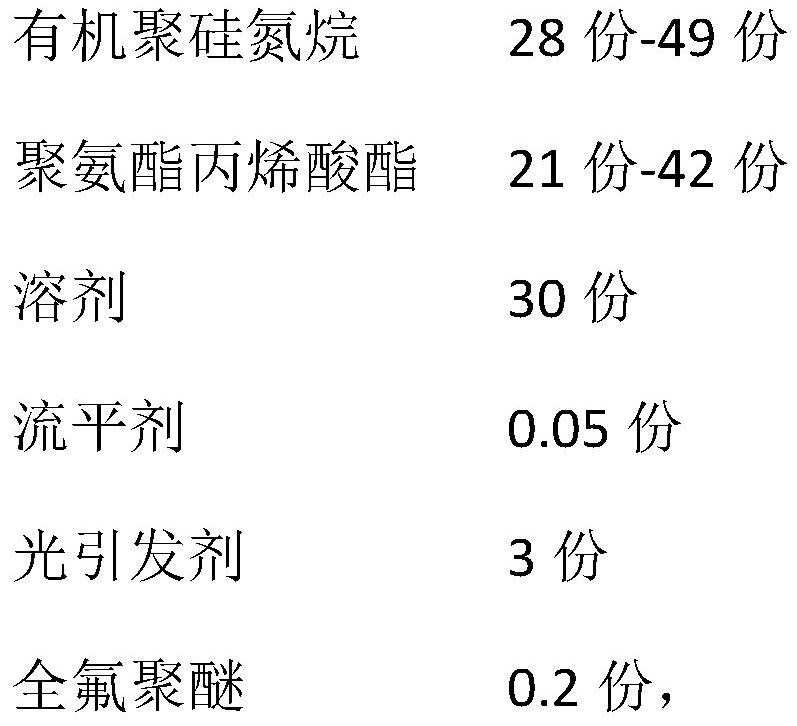

[0049] 1. Hardened layer coating

[0050] Dissolve 49 parts by weight of organopolysilazane 1500RC [DURAZANE] and 21 parts by weight of polyurethane acrylate 6197H [Changxing Chemical; functionality 6] into 30 parts by weight of propylene glycol monomethyl ether solvent, add 0.05 parts by weight for leveling agent BYK-377 [BYK], and add 3 parts by weight of photoinitiator 184 [BASF] and 0.2 parts by weight of perfluoropolyether AF-01 [Lucky] to obtain a hardening solution for later use.

[0051] The above hardening solution was applied to one side of a polyethylene terephthalate film [Lucky; elastic modulus 5000 MPa] with a thickness of 25 μm, and after drying the formed coating at 150° C. for 2 minutes, it was irradiated with 172 nm ultraviolet rays 1min, and then irradiated with 280nm ultraviolet rays for 1min to obtain a hardened layer with a thickness of 1μm.

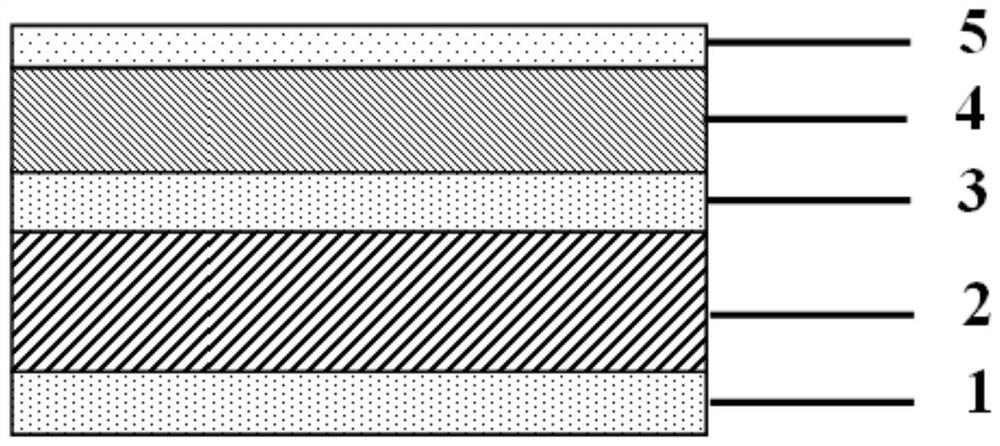

[0052] 2. Fitting of the protective cover

[0053] Use 100 μm OCA glue [Mitsubishi] to bond 50 μm ultra-thin gl...

Embodiment 2

[0055] 1. Hardened layer coating

[0056] Dissolve 42 parts by weight of organopolysilazane 1500SC [DURAZANE] and 28 parts by weight of polyurethane acrylate UA9050 [BASF; functionality 8] into 30 parts by weight of butanone solvent, add 0.05 parts by weight of leveling agent BYK- 307 [BYK], and add 3 parts by weight of photoinitiator 1173 [BASF] and 0.2 parts by weight of perfluoropolyether DAC-HP [Dakin in Japan] to obtain a hardening solution for future use.

[0057] The above hardening solution was applied to one side of a polyethylene terephthalate film [Lucky; elastic modulus of 5873 MPa] with a thickness of 28 μm, and after drying the formed coating at 150° C. Irradiate for 1 min, and then irradiate with 295nm ultraviolet rays for 1 min to obtain a hardened layer with a thickness of 2.5 μm.

[0058] 2. Fitting of the protective cover

[0059] Use 125 μm OCA glue [Mitsubishi] to bond 80 μm ultra-thin glass [Nippon Electric Glass] to the above-mentioned polyethylene ter...

Embodiment 3

[0061] 1. Hardened layer coating

[0062] Dissolve 35 parts by weight of organopolysilazane 1800 [DURAZANE] and 35 parts by weight of polyurethane acrylate CN9013NS [Sartomer; functionality 9] into 30 parts by weight of ethanol solvent, add 0.05 parts by weight of leveling agent TEGORad 2100 [TEGO], and add 3 parts by weight of photoinitiator TPO [BASF] and 0.2 parts by weight of perfluoropolyether CoatFilmUVF-103 [Konu new material] to obtain a hardening solution for future use.

[0063] The above hardening solution was applied to one side of a polyethylene terephthalate film [Lucky; elastic modulus of 6645 MPa] with a thickness of 36 μm, and after drying the formed coating at 150° C. for 2 minutes, it was sprayed with 172 nm ultraviolet rays Irradiate for 1 min, and then irradiate with 320nm ultraviolet rays for 1 min to obtain a hardened layer with a thickness of 4 μm.

[0064] 2. Fitting of the protective cover

[0065] Use 150μm OCA glue [Fuyin Group] to bond 125μm ultr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com