Preparation method of high-cleanliness ultrashort viscose fibers for papermaking

A viscose fiber, high cleanliness technology, used in the field of light industrial textiles, can solve the problems of uneven whiteness inside and outside the viscose fiber tow, inability to remove impurities in the viscose fiber tow, and large damage to the viscose fiber tow. , to achieve the effect of slow forward speed, reduced strength, and reduced damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

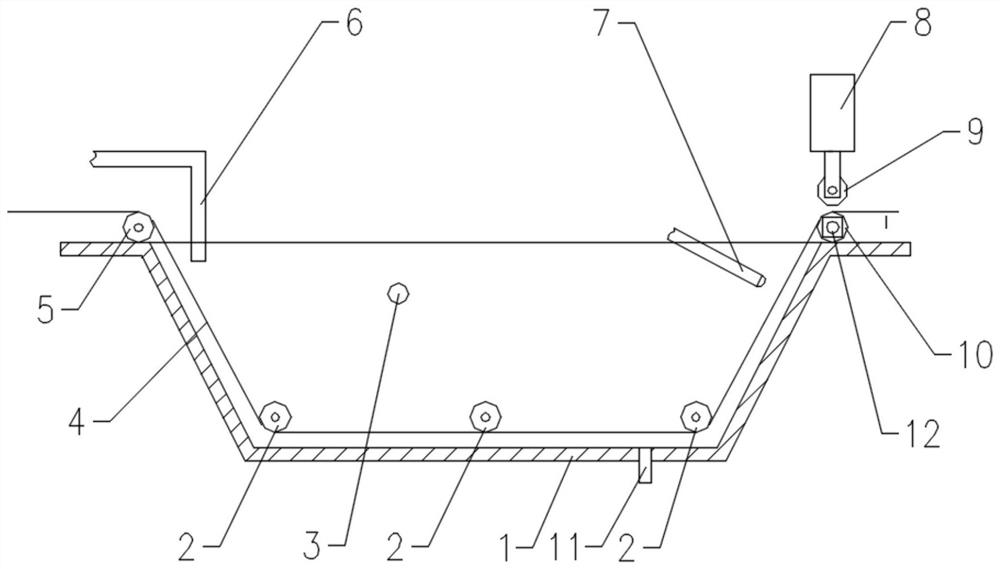

Image

Examples

Embodiment

[0033] Embodiment: a kind of preparation method of ultra-short viscose fiber with high cleanliness for papermaking, described preparation method comprises the following steps:

[0034] (1), bleaching

[0035] Take 6g / L of hydrogen peroxide with a solid content of 30%, 5g / L of TAED, and 2g / L of sodium carbonate, and add them to the bath. The ratio of hydrogen peroxide, TAED, and sodium carbonate is 6:5:2. Sodium 4.8kg, bleach the viscose fiber tow at a temperature of 35°C for 10 minutes, and drain the mixture after the bleaching is completed. The advancing speed of the viscose fiber tow in the bath is 0.8m / min, and the length of each bag of viscose fiber tow is 80m. The viscose fiber tow enters from one end of the bath and then outputs from the other end for 10 minutes. It takes 100 minutes for all the viscose fiber tow in the bag 80m to pass through the bath.

[0036] (2), neutralization

[0037] Fill the bath with water, add 2.4kg of solid citric acid into the bath at a co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com