Immersion liquid supply system and immersion flow field initial establishment method

A technology of immersion liquid and flow field, which is applied in optics, instruments, optomechanical equipment, etc., can solve the problems that are difficult to eliminate, prolong the consumption time, generate air bubbles and pollutants, and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

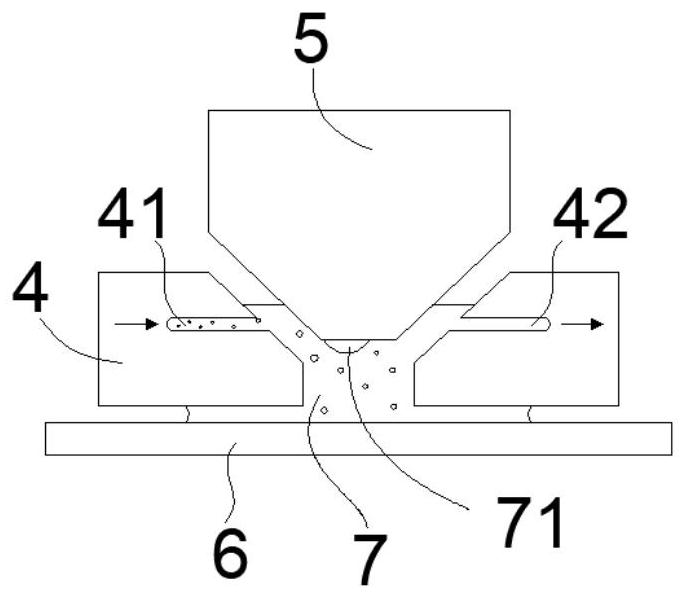

[0031] like figure 1 As shown, the immersion lithography machine includes the terminal objective lens 5 of the projection objective lens system, the substrate 6, and the immersion liquid supply and recovery device arranged around the radially outer side of the terminal objective lens 5 and above the substrate 6; the immersion liquid supply and recovery device 4 passes through the main The liquid injection port 41 provides immersion liquid to the space between the terminal objective lens 5 and the substrate 6 , and the immersion liquid is drawn from the space through the main pumping outlet 42 to form an immersion flow field between the terminal objective lens 5 and the substrate 6 . The exposure laser beam carrying the integrated circuit pattern passes through the terminal objective lens 5 and the immersion flow field 7, and is projected on the substrate 7, so that the photoresist on the surface of the substrate 7 is photosensitively modified, thereby leaving the integrated cir...

Embodiment 2

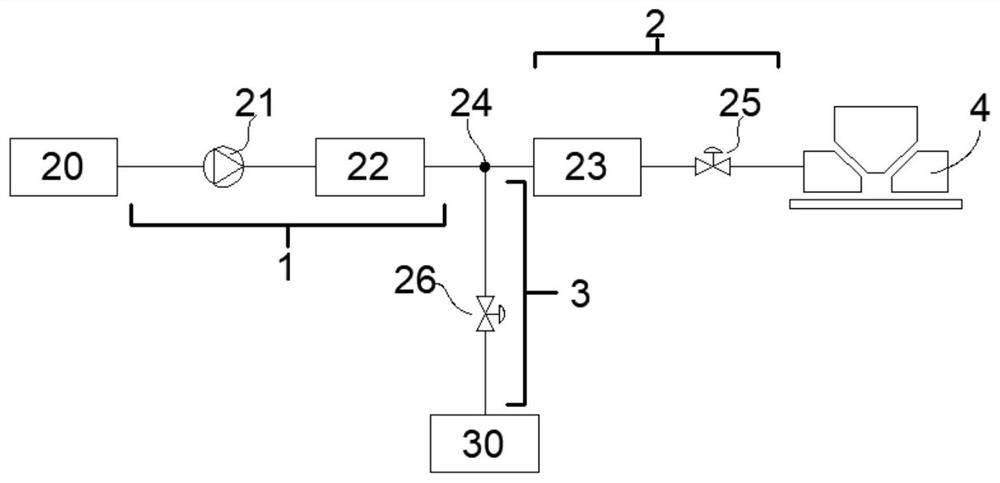

[0037] like Figure 5 As shown, the first flow path 1 includes a power source 21 , an immersion liquid purification component 22 and an immersion liquid flow adjustment component 23 , and the second flow path 2 includes a liquid supply valve 25 . In the initial establishment process of the immersion flow field, firstly close the liquid supply valve 25, open the bypass valve 26, and discharge the immersion liquid to the discharge port through the first flow path 1 and the third flow path 3; wait for the immersion liquid quality and flow parameters After reaching the target range, close the bypass valve 26, open the liquid supply valve 25, so that the immersion liquid is supplied to the immersion liquid supply device 4 through the first flow path 1 and the second flow path 2, and further form an immersion flow field; the other embodiments are the same as Embodiment one.

[0038] Preferably, the length of the pipeline between the connection point 24 and the immersion liquid supp...

Embodiment 3

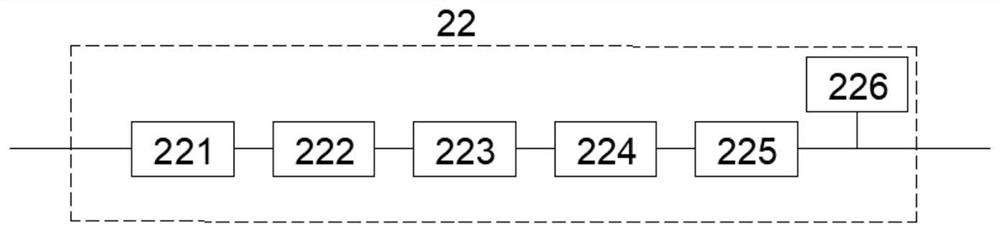

[0041] like Image 6 As shown, the first flow path 1 includes a power source 21, an immersion liquid purification assembly 22, and an immersion liquid flow adjustment assembly 23, and a degasser 221 or a filter 225 is provided downstream of the immersion liquid flow adjustment assembly 23 in the first flow path 1 Or its combination; All the other implementation modes are the same as in Embodiment 2.

[0042] Because factors such as bends and gaps in the pipeline of the immersion liquid flow adjustment component 23 may introduce pollutants such as air bubbles and particles into the immersion liquid, using the immersion liquid supply system of this embodiment can remove pollution such as air bubbles in the immersion liquid again and further improve the reliability of the quality and reliability of the immersion liquid output by the immersion liquid supply system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com