Factory-like prawn culture wastewater treatment method

A technology for breeding wastewater and treatment methods, which is applied in animal husbandry wastewater treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve problems such as farm environmental pollution, offshore ecological crisis, and nearby sea area pollution, and achieve improvement The growth environment, significant environmental protection benefits, and the effect of reasonable methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

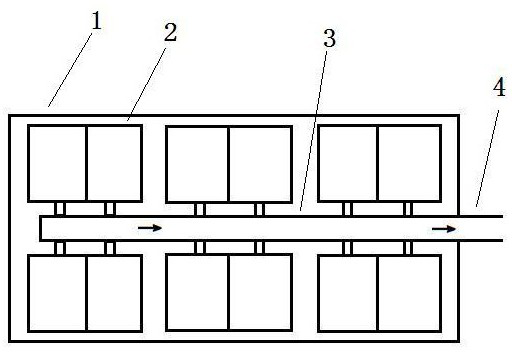

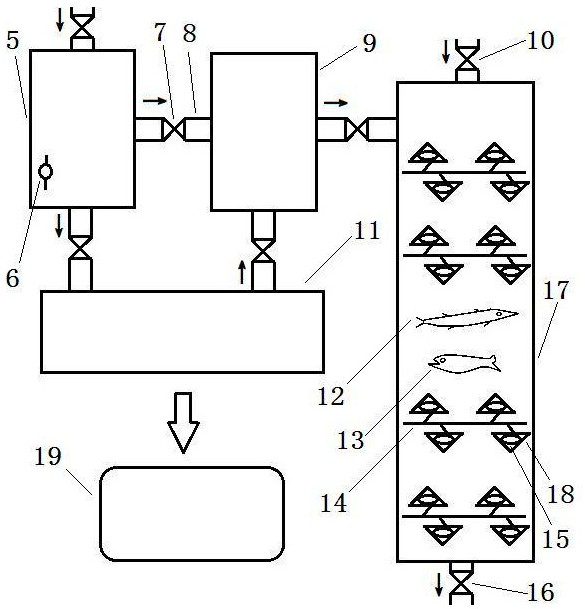

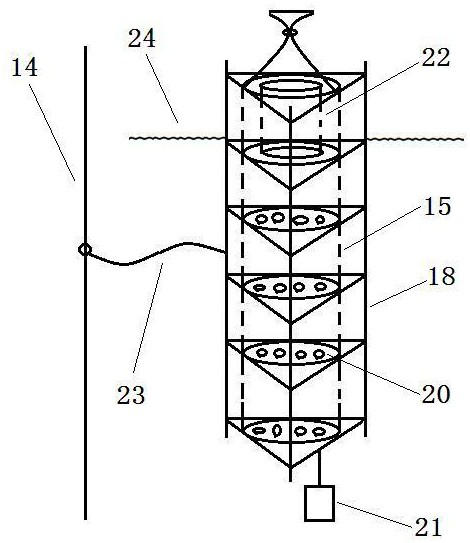

[0040] see figure 1 , figure 2 and image 3 . A kind of treatment method of industrialized prawn culture waste water, comprises the steps:

[0041] (1) Build wastewater treatment facilities outdoors: build an adsorption pond 5, a ventilation pond 9, a sediment recovery pond 11, and a biological purification pond 17 outside the industrialized shrimp farming workshop 1; The pipeline 8 is connected to the ventilation pool 9 and the biological purification pond 17 in turn; the sediment recovery tank 11 is respectively connected to the adsorption pool 5 and the ventilation pool 9 through the water pipeline 8 equipped with the valve 7; between the wastewater treatment facilities, the waste water depends on the water level difference natural flow in and out;

[0042] (2) Add muddy silt from the tidal flat to the workshop wastewater: when the wastewater is discharged from the culture pond 2 of the industrial shrimp farming workshop 1, put muddy silt at the exit 4 of the wastewate...

Embodiment 2

[0053] see figure 1 , figure 2 and image 3 . A method for treating industrialized prawn farming wastewater. On the basis of the technical solution recorded in Example 1, step (1) the adsorption pool 5, the ventilation pool 9 and the sediment recovery pool 11 all use cement pools, which are durable and durable. It is easy to clean and saves cost; step (1) the material of the water pipeline 8 is PVC, which is both anti-corrosion and cheap.

Embodiment 3

[0055] see figure 1 , figure 2 and image 3 . A method for treating industrialized prawn farming wastewater. On the basis of the technical solution recorded in Example 1, step (1) the depth of the ventilation pool 9 is 30 cm, and the wastewater level is 20 cm. Such a shallow water level is conducive to the rapid increase of wastewater dissolved oxygen concentration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com