Flue gas treatment system and method

A flue gas treatment system and flue gas treatment technology are applied in separation methods, chemical instruments and methods, and separation of dispersed particles, which can solve the problems of complex equipment structure, high investment and operating costs, and achieve simple reaction principles, low prices, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

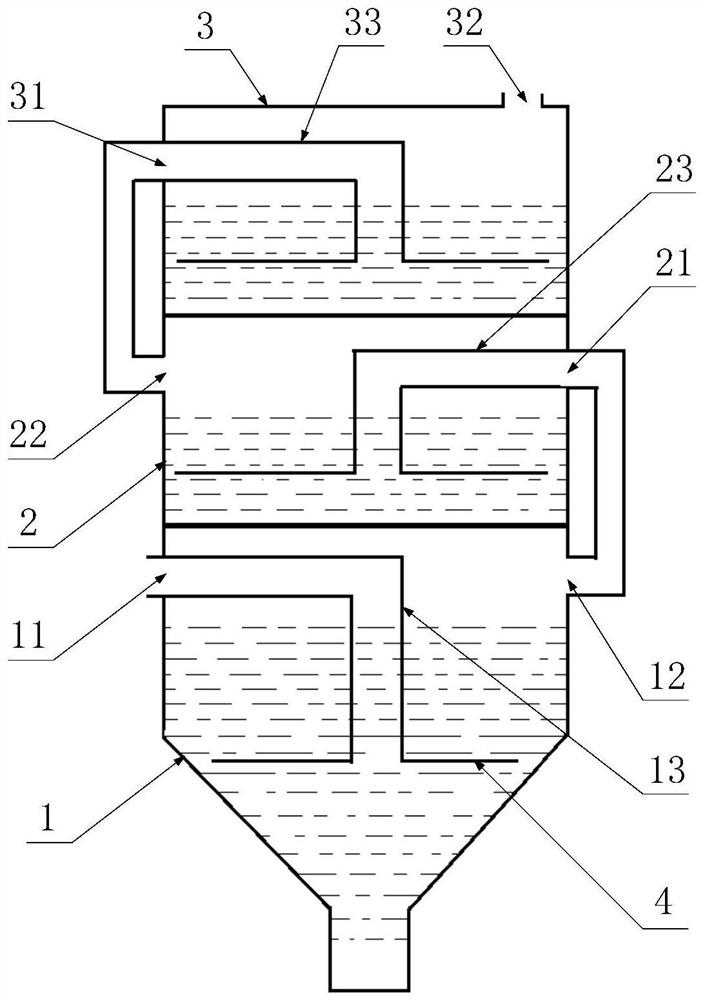

[0032] For ease of understanding, the present invention will be further described below in conjunction with the accompanying drawings.

[0033] see figure 1 , the flue gas treatment system provided by the embodiment of the present invention includes a first box body 1, a second box body 2 and a third box body 3, wherein the first box body 1 contains water, and the liquid level of the first box body 1 The above part is provided with a first inlet 11 and a first outlet 12, and a first conduit 13 is arranged in the first tank 1, one end of the first conduit 13 is connected to the first inlet 11, and the other end is submerged below the liquid surface.

[0034] The structure of the second box body 2 and the third box body 3 is similar to the structure of the first box body 1, but what they are filled with is not water, wherein, urea and sodium hydroxide or sodium carbonate are filled in the second box body 2 The mixed solution, the dilute sulfuric acid solution is filled in the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com