Non-molecular polymeric phase material and preparation method thereof

A molecular, reciprocating rotation technology, applied in the field of non-molecular polymeric phase materials and their preparation, can solve the problems of unstable configuration, incomplete conversion of non-molecular polymerization, etc., and achieve the effects of low cost, low synthesis pressure and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The invention provides a method for preparing a non-molecular polymeric phase material, comprising the following steps:

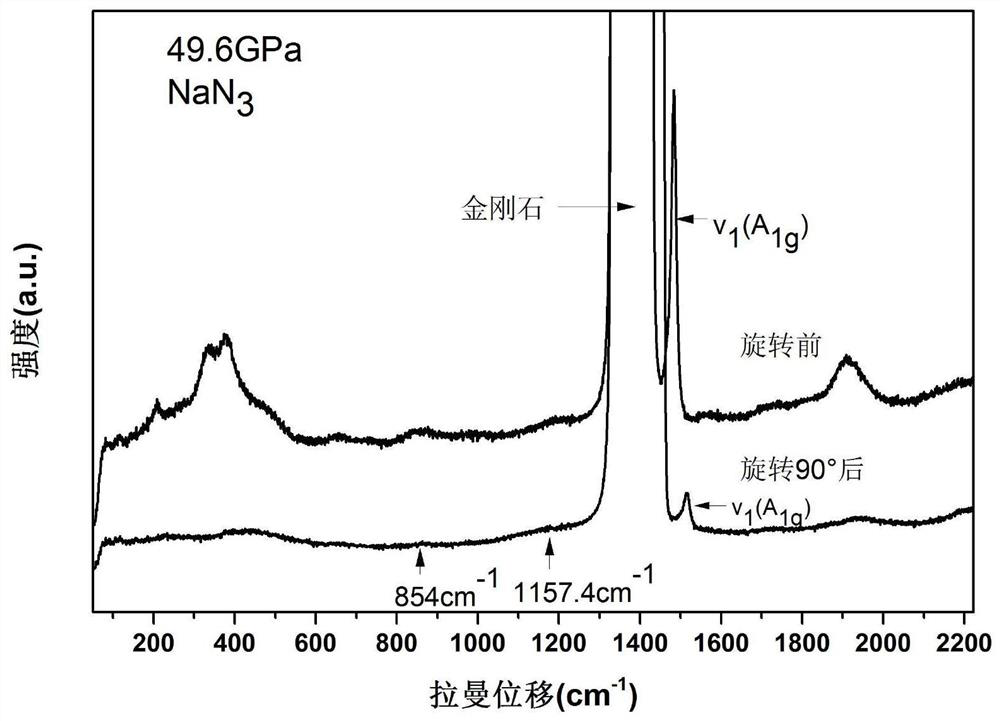

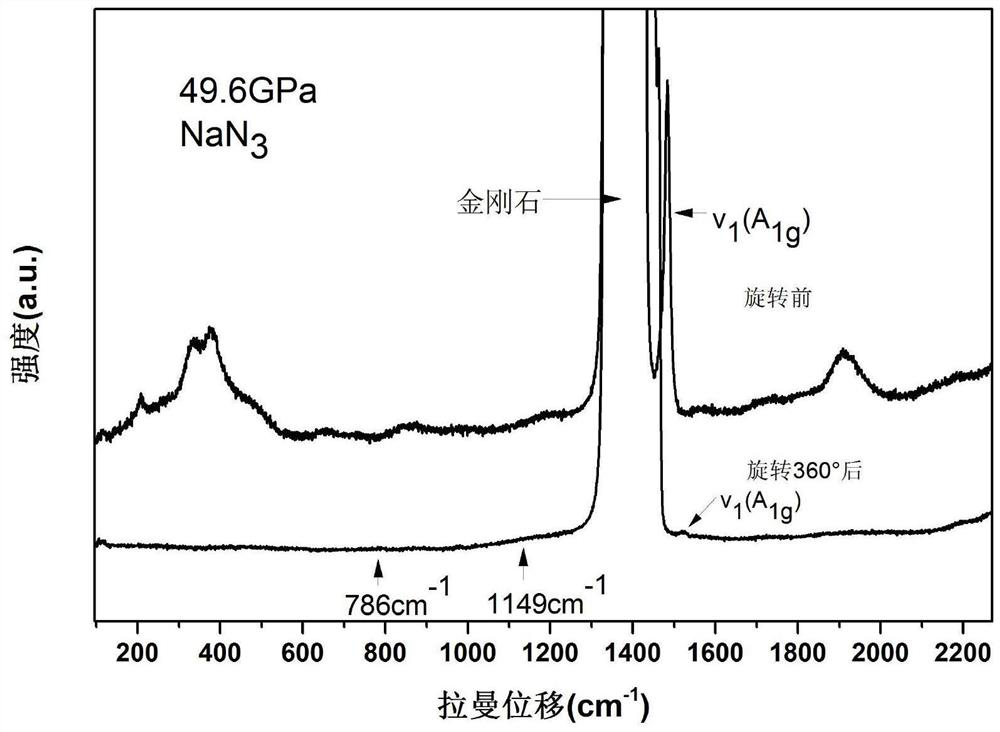

[0020] Put the sodium azide powder in the pressurizing device, after pressurizing to 49.6-51GPa, take 45-90° as a rotation cycle, carry out reciprocating rotation, apply shear stress, and stop when the total angle of reciprocating rotation is ≥405° Spin to obtain a non-molecular polymeric phase material.

[0021] In the present invention, unless otherwise specified, the required preparation materials or devices are commercially available products well known to those skilled in the art.

[0022] In the present invention, the pressurizing device is preferably an unbalanced load static high-pressure press; the present invention has no special limitation on the unbalanced load static high-pressure press, and the corresponding device well known in the art is sufficient, specifically a diamond pair Anvil press, the anvil face of the diamond-to-anvil press...

Embodiment 1

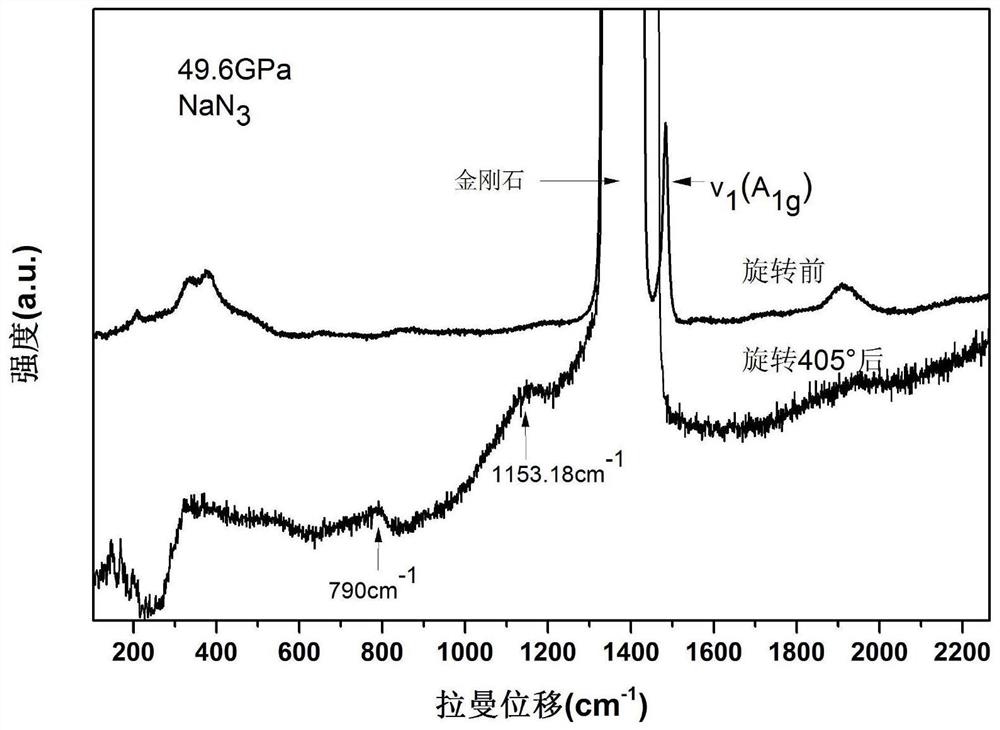

[0029] Use a diamond with an anvil surface of 200 μm to pre-press the rhenium sheet, and drill a circular hole with a diameter of 66 μm in the center of the indentation. The circular hole is used as a sample cavity for loading raw materials, and the excess sodium azide powder is filled Install it into the sample chamber, add two ruby balls with a diameter of 3 μm as the pressure standard, do not add any other medium as the pressure transmission medium, and pressurize at a rate of 4GPa / min. When the pressure is increased to 49.6GPa, the Rotate at a rate of 45° in 10s, 45° is a rotation period, and rotate 405° to obtain a non-molecular polymeric phase material.

[0030] Raman scattering test is carried out to the non-molecular polymeric phase material prepared in this embodiment, the results are shown in figure 1 ;Depend on figure 1 It can be seen that the stretching vibration v1 of azide ion disappears, and the decomposition of sodium azide disappears. At 790cm -1 、1153.18c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com