High-performance economical asphalt mixture and construction method thereof

A technology of asphalt mixture and construction method, which is applied in the direction of cohesive pavement paved on site, roads, roads, etc., which can solve the problems of water tightness and anti-rutting, anti-skid, and uneven quality of ultra-thin wear layer materials Problems such as unevenness and poor durability of maintenance surface materials achieve the effects of cheap construction, increased lightweight, and excellent high-temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

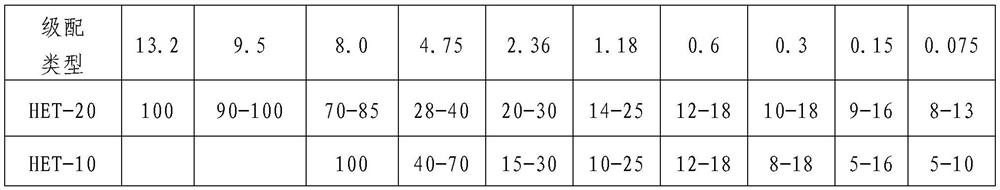

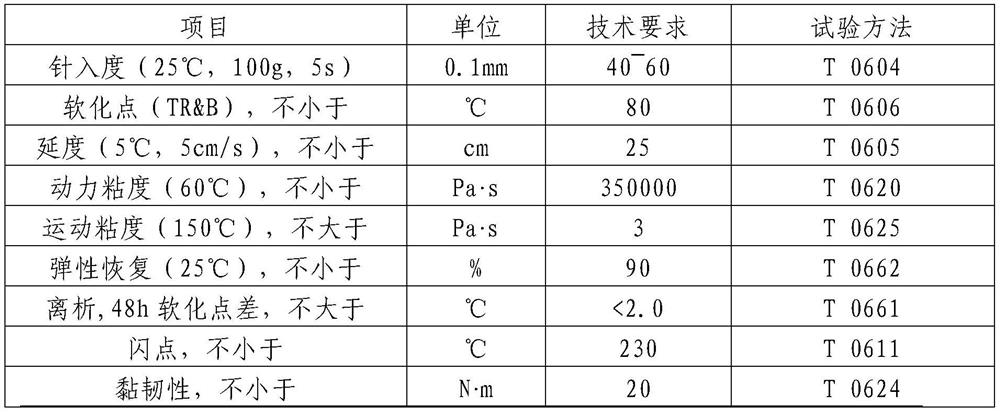

[0086] High-performance asphalt mixture is used as the upper layer. The wear-resistant thin layer is numbered HET-20. The paving thickness is 2.5cm. The mineral materials are 5-10mm diabase coarse aggregate and 0-3mm diabase fine aggregate. , limestone slag composition, the mass fraction is 75%: 16%: 9%, the design gradation is as follows in Table 12; high-viscosity modified asphalt is used, the index meets Table 1, and the asphalt ratio is 6.3%; flocculent lignin fiber is used as Stabilizer, its mass fraction is 0.3% of the total mass of the asphalt mixture; the bonding layer adopts high-performance modified emulsified asphalt.

[0087] Table 12 HET-20 Design Grading

[0088]

[0089] The preparation method of the high-performance and economical wearing layer asphalt mixture comprises the following steps:

[0090] (1) Firstly, the required coarse and fine aggregates are mixed according to the target mixing ratio, transported to the rotary kiln by belt, heated for 12s, hea...

Embodiment example 2

[0099] High-performance asphalt mixture is used as the upper layer. The wear-resistant thin layer is numbered HET-10, and the paving thickness is 1.5cm. The mineral material is composed of 5-10mm basalt coarse aggregate, 0-3mm basalt fine aggregate, and limestone mineral powder. , the mass fraction is 73%: 21%: 6%, and the design gradation is as follows in Table 15; using high-viscosity modified asphalt, the index meets Table 1, and the asphalt ratio is 7.0%; The fraction is 0.4% of the total mass of asphalt mixture;

[0100] Table 15 HET-10 asphalt mixture ore grading

[0101]

[0102] The preparation method of the asphalt mixture includes the following steps: (1) First, mix the required coarse and fine aggregates according to the target mixing ratio, transport them to the rotary kiln by a belt, heat them for 15 seconds, and heat them to 185°C. High-viscoelastic modified asphalt is preheated to 170°C; (2) The aggregate heated by the rotary kiln is screened for the second ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com