A kind of preparation method of natural flexible transparent paper

A transparent paper and flexible technology, which is applied in the field of preparation of natural flexible transparent paper, can solve the problems of high thermal expansion coefficient, slow development of flexible organic synthetic polymer paper, and low processing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

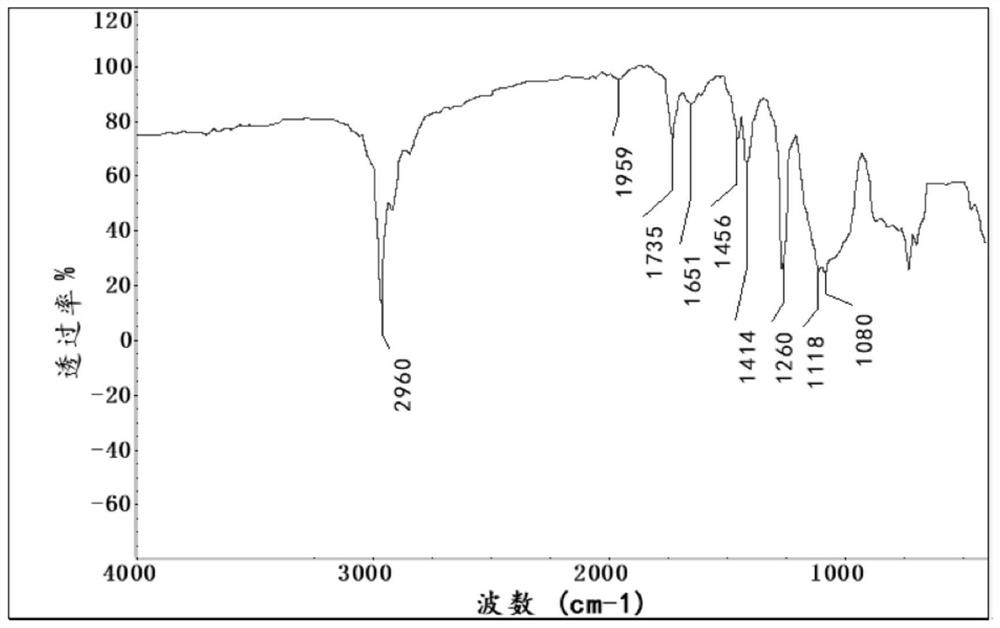

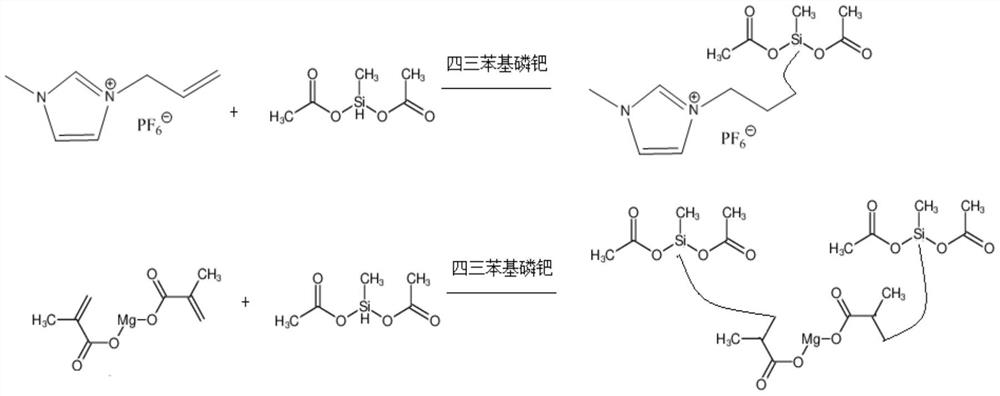

Image

Examples

Embodiment 1

[0031] A kind of preparation method of natural flexible transparent paper, its operation steps are:

[0032]Prepare the dissolved wood pulp into a 0.5% concentration of dissolved wood pulp, then add 20%-80% nano-cellulose suspension, stir and mix evenly, and use a paper sheet machine to copy the wood pulp into base paper. After completion, it will be made into The raw paper is placed in a drying oven at 100°C for 60 minutes, and then the silicon-containing ionic liquid transparent agent is added at a rate of 0.1g / m 2 Evenly spread the amount on the surface of the base paper, and let it stand at 40°C for 60 minutes; then heat the base paper at a temperature of 80°C, a pressure of 0.5MPa, and a time of 5 minutes. After the treatment, the base paper is washed in ethanol, and then repeated After hot pressing for 30 minutes, the natural flexible transparent paper can be obtained.

[0033] The preparation method of described nanocellulose suspension is as follows:

[0034] Add 3kg...

Embodiment 2

[0042] A kind of preparation method of natural flexible transparent paper, its operation steps are:

[0043] Prepare the dissolved wood pulp into a 2.5% concentration of dissolved wood pulp, then add 50% nano-cellulose suspension, stir and mix evenly, and use a paper hand-sheet machine to copy the wood pulp into base paper. After completion, make the base paper Place it in a drying oven at 110°C for 90 minutes, and then put the silicon-containing ionic liquid transparent agent at a rate of 0.5g / m 2 Evenly spread the amount on the surface of the base paper, and let it stand at 50°C for 70 minutes; then heat the base paper at a temperature of 100°C, a pressure of 2.5MPa, and a time of 15 minutes. After the treatment, the base paper is washed in ethanol, and then repeated After hot pressing for 40 minutes, the natural flexible transparent paper can be obtained.

[0044] The preparation method of described nanocellulose suspension is as follows:

[0045] Add 5kg of dissolved woo...

Embodiment 3

[0053] A kind of preparation method of natural flexible transparent paper, its operation steps are:

[0054] Prepare the dissolved wood pulp into a 5% concentration of dissolved wood pulp, then add 80% nano-cellulose suspension, stir and mix evenly, and use a paper sheet machine to copy the wood pulp into base paper. After completion, make the base paper Place in a drying oven at 120°C to dry for 120 minutes, and then put the silicon-containing ionic liquid transparent agent at a rate of 0.8g / m 2 The amount of the base paper is evenly coated on the surface of the base paper, and the base paper is placed at 60°C for 80 minutes; then the base paper is subjected to hot-pressing treatment at a temperature of 120°C, a pressure of 5MPa, and a time of 30 minutes. After the treatment, the base paper is washed in ethanol, and then repeated heating After pressing for 60 minutes, the natural flexible transparent paper can be obtained.

[0055] The preparation method of described nanocel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com